This is an oversize product. Additional shipping fees may apply.

This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

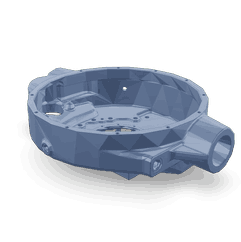

The Cummins 3045201 Flywheel Housing is a critical component designed for use in commercial trucks. It plays a significant role in the operation of these vehicles by providing a secure enclosure for the flywheel and facilitating the interaction between the engine and transmission systems.

Basic Concepts of Flywheel Housing

A flywheel housing is a protective casing that encloses the flywheel, a heavy rotating disc that stores rotational energy and smooths out the power delivery from the engine 1. This housing maintains the flywheel’s position, protects it from external elements, and ensures efficient power transfer between the engine and transmission. It integrates with other engine components by securing the flywheel in place and allowing for the proper engagement of the clutch 2.

Purpose of the 3045201 Flywheel Housing

The 3045201 Flywheel Housing is designed to facilitate the interaction between the flywheel, clutch, and transmission system, ensuring smooth and efficient power transfer. This housing allows for the proper alignment and secure mounting of the flywheel, which is essential for the consistent operation of the clutch and transmission.

Key Features

This part is constructed from durable materials, ensuring it can withstand the rigors of heavy-duty applications. Its design includes precise mounting points for the flywheel and clutch, enhancing the overall performance and reliability of the engine system. Unique characteristics such as reinforced sections and optimized weight distribution contribute to its durability and efficiency 3.

Benefits

The 3045201 Flywheel Housing offers several benefits, including improved engine performance through efficient power transfer and enhanced durability due to its robust construction. Its reliable design ensures consistent operation in heavy-duty applications, contributing to the overall reliability of the truck’s engine system 4.

Installation Process

Installing the 3045201 Flywheel Housing involves several steps to ensure proper integration with the engine system. Begin by preparing the engine bay, ensuring all necessary tools and components are available. Secure the housing in place using the provided mounting hardware, ensuring it is aligned correctly with the flywheel and clutch. Double-check all connections and bolts to confirm they are tightened to the manufacturer’s specifications. Finally, perform a test run to ensure the housing is functioning correctly and there are no issues with the clutch or transmission engagement.

Maintenance Tips

To ensure the optimal performance and longevity of the 3045201 Flywheel Housing, regular maintenance is recommended. Inspect the housing for any signs of wear or damage during routine engine checks. Clean the exterior to remove any debris or buildup that could affect its operation. Lubricate moving parts as necessary to reduce friction and wear. Addressing any issues promptly can help prevent more significant problems down the line.

Troubleshooting Common Issues

Common issues with the 3045201 Flywheel Housing may include misalignment, wear on mounting points, or damage to the housing itself. To troubleshoot these problems, first, ensure the housing is correctly aligned with the flywheel and clutch. Inspect the mounting points for any signs of wear or damage, and replace any worn components as needed. If the housing is damaged, it may need to be replaced to ensure the proper operation of the engine system.

Cummins Overview

Cummins Inc. is a leading manufacturer of diesel engines, known for its high-quality products and innovative solutions in the commercial truck industry. With a history of providing reliable and efficient engine components, Cummins has established a strong reputation for excellence. The 3045201 Flywheel Housing is part of Cummins’ extensive product range, designed to meet the demanding requirements of heavy-duty applications.

Compatibility with Cummins Engines

The Flywheel Housing part 3045201, manufactured by Cummins, is designed to fit seamlessly with several of their engine models. This part is compatible with the L10 MECHANICAL and M11 MECHANICAL engines, ensuring a secure and efficient connection. Additionally, it is suitable for the M11 CELECT PLUS and QSM11 CM570 engines, providing a reliable housing for the flywheel mechanism.

For the L10 MECHANICAL and M11 MECHANICAL engines, the flywheel housing part 3045201 is engineered to match the specific design and requirements of these mechanical engines, ensuring optimal performance and durability. The same part is also suitable for the M11 CELECT PLUS, which benefits from the robust construction and precision engineering of the housing.

In the case of the QSM11 CM570 engine, the flywheel housing part 3045201 is tailored to fit the unique specifications of this model, ensuring that the flywheel operates smoothly and efficiently. This compatibility across different engine types highlights the versatility and reliability of the Cummins flywheel housing part 3045201.

Role of Part 3045201 Flywheel Housing in Engine Systems

The flywheel housing, designated as part 3045201, is an integral component in the engine system, working in concert with various other parts to ensure optimal engine performance and durability.

Integration with the Engine Oil Cooler

The flywheel housing plays a significant role when integrated with the engine oil cooler. The oil cooler is responsible for maintaining the oil at an optimal temperature, which is vital for the lubrication and cooling of engine components. The flywheel housing, by virtue of its positioning and design, helps in shielding the oil cooler from external contaminants and excessive heat. This shielding ensures that the oil cooler operates efficiently, thereby contributing to the overall thermal management of the engine 5.

Structural and Functional Synergy

Beyond thermal management, the flywheel housing also provides structural support to the engine system. It encases the flywheel, which is a heavy, rotating disc that stores rotational energy and smooths out the power delivery from the engine. The housing protects the flywheel from external impacts and vibrations, which could otherwise lead to damage or misalignment.

Moreover, the flywheel housing is often designed with precision to align with other components such as the clutch assembly and the transmission system. This alignment ensures that the rotational energy stored in the flywheel is efficiently transferred to the transmission, facilitating smooth gear changes and consistent power delivery.

Enhanced Engine Stability

The flywheel housing also contributes to the overall stability of the engine. By securely holding the flywheel in place, it reduces the likelihood of mechanical failures that could arise from flywheel misalignment. This stability is particularly important in high-performance engines where precision and reliability are paramount.

Conclusion

In summary, the 3045201 Flywheel Housing is not just a protective enclosure but a component that enhances the functionality and reliability of the engine system, working in harmony with parts like the engine oil cooler to ensure optimal performance.

-

Forbes Aird, Bosch Fuel Injection Systems, HP Books, 2001.

↩ -

Michael Hilgers, Vocational Vehicles and Applications, Springer Nature, 2023.

↩ -

Jon M. Quigley, SAE International’s Dictionary of Testing, Verification and Validation, SAE International, 2023.

↩ -

Libby Osgood, Gayla Cameron, and Emma Christensen, Engineering Mechanics: Statics, Creative Commons, 2024.

↩ -

Cummins Inc., Owners Manual for ISF3.8 CM2220 F110, Bulletin Number 4358481.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.