This is an oversize product. Additional shipping fees may apply.

This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

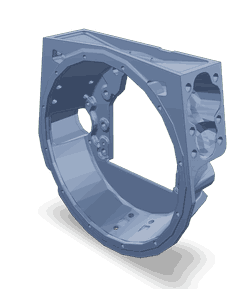

The Cummins 3101771 Flywheel Housing is a critical component designed for use in commercial trucks. It plays a significant role in the operation of these vehicles by housing the flywheel, which is integral to the engine’s functionality. Understanding its purpose and significance is key to maintaining and optimizing the performance of commercial trucks.

Basic Concepts of Flywheel Housing

A flywheel housing is a protective enclosure that houses the flywheel, a heavy rotating disc that stores rotational energy. This housing plays a role in the engine system by providing a secure environment for the flywheel, shielding it from external elements and ensuring smooth operation. It also facilitates the integration of the flywheel with other engine components, such as the clutch and transmission, contributing to the overall efficiency and performance of the engine 1.

Purpose and Role of the 3101771 Flywheel Housing

The 3101771 Flywheel Housing is specifically designed to accommodate the flywheel in Cummins engines. It plays a role in the operation of a truck by ensuring the flywheel is securely held in place, allowing for efficient energy transfer between the engine and the transmission. This housing contributes to engine performance by maintaining the alignment and integrity of the flywheel, which is crucial for smooth gear changes and consistent power delivery 2.

Key Features

The 3101771 Flywheel Housing is characterized by several key features that enhance its functionality. It is constructed from durable materials to withstand the rigors of commercial truck operation. Its design includes precise machining to ensure a perfect fit with the flywheel and other engine components. Additionally, it features mounting points and alignment dowels that facilitate accurate installation and operation.

Benefits of Using the 3101771 Flywheel Housing

Utilizing the 3101771 Flywheel Housing offers several benefits. It contributes to improved engine efficiency by providing a secure and stable environment for the flywheel. Its durable construction enhances the longevity of the component, reducing the need for frequent replacements. Moreover, its design ensures compatibility with specific Cummins engines, optimizing performance and reliability.

Installation Process

Installing the 3101771 Flywheel Housing requires careful attention to detail. The process involves ensuring the engine is properly prepared, with all necessary components cleaned and inspected. Tools such as torque wrenches and alignment tools are required to secure the housing in place and ensure it is correctly aligned with the flywheel and other engine components. Following manufacturer guidelines for torque specifications and alignment is crucial for a successful installation 3.

Troubleshooting Common Issues

Common issues with the 3101771 Flywheel Housing may include misalignment, wear, or damage. Troubleshooting these problems involves inspecting the housing for signs of damage, ensuring it is correctly aligned with the flywheel, and checking for proper installation. Solutions may range from realigning the component to replacing damaged parts, depending on the issue identified.

Maintenance Tips

To prolong the lifespan of the 3101771 Flywheel Housing, regular maintenance is recommended. This includes inspecting the housing for signs of wear or damage, cleaning it to remove any debris or contaminants, and ensuring it remains properly aligned with the flywheel. Regular maintenance helps prevent issues and ensures the housing continues to function effectively.

Compatibility and Application

The 3101771 Flywheel Housing is designed for specific Cummins engines and truck models. It is important to consult compatibility information to ensure the housing is suitable for the intended application. Specific application notes may include requirements for engine preparation or additional components to ensure optimal performance.

About Cummins

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a history of innovation and quality, Cummins has established a reputation for reliability and performance in the commercial truck industry. The 3101771 Flywheel Housing is a testament to Cummins’ commitment to providing high-quality components that enhance the efficiency and durability of commercial trucks.

Understanding the Integration of Part 3101771 Flywheel Housing in Engine Systems

The flywheel housing, designated as part 3101771, is an integral component in the assembly and operation of various engine systems. Its primary function is to encase and support the flywheel, which plays a significant role in stabilizing the engine’s rotational energy.

Interaction with Key Engine Components

Flywheel

The flywheel housing securely holds the flywheel in place. The flywheel, in turn, stores rotational energy and smooths out the power delivery from the engine’s combustion cycles. This interaction ensures consistent engine operation and reduces vibrations 4.

Clutch Assembly

In manual transmission systems, the flywheel housing interfaces with the clutch assembly. The pressure plate, which is part of the clutch assembly, exerts force on the flywheel to engage or disengage the clutch. The housing provides the necessary structural support for this mechanism.

Torque Converter (Automatic Transmissions)

In automatic transmission systems, the flywheel housing may interact with the torque converter. The torque converter uses fluid coupling to transfer engine power to the transmission. The housing ensures that the flywheel remains aligned and securely positioned during this process.

Engine Mounts

The flywheel housing is often bolted to the engine block and connected to the transmission bell housing. This connection is vital for maintaining the structural integrity of the engine and transmission assembly. The housing helps distribute the forces generated by the engine throughout the mounting system.

Starter Motor

During engine start-up, the starter motor engages with the flywheel, which is housed within the flywheel housing. The housing provides a stable platform for this engagement, ensuring that the starter motor can effectively crank the engine.

Role in Engine Balance and Noise Reduction

The flywheel housing also contributes to the overall balance of the engine. By securely holding the flywheel, it helps minimize rotational imbalances that could lead to increased wear on engine components and excessive noise. Additionally, the housing can incorporate damping materials or designs to further reduce noise and vibration transmitted to the chassis.

Thermal Management

In some engine designs, the flywheel housing may incorporate features for thermal management. These features help dissipate heat generated by the flywheel and clutch assembly, contributing to the overall reliability and performance of the engine system.

Maintenance and Inspection

Regular inspection of the flywheel housing is essential for identifying potential issues such as cracks, wear, or misalignment. Proper maintenance ensures that the housing continues to perform its function effectively, supporting the flywheel and other connected components.

Conclusion

In summary, the flywheel housing (part 3101771) plays a multifaceted role in engine systems, interacting with various components to ensure smooth operation, structural integrity, and efficient power transmission. Its design and construction are critical to the performance and longevity of commercial truck engines.

-

Awari, G.K., Kumbhar, V.S., & Tirpude, R.B. (2011). Automotive Systems Principles and Practice. CRC Press.

↩ -

Reif, K. (Ed.). (2015). Gasoline Engine Management Systems and Components. Springer Vieweg.

↩ -

Hilgers, M. (2023). Chassis and Axles. Springer Vieweg.

↩ -

Sheng, G. (2012). Vehicle Noise, Vibration and Sound Quality. SAE International.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.