This is an oversize product. Additional shipping fees may apply.

This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

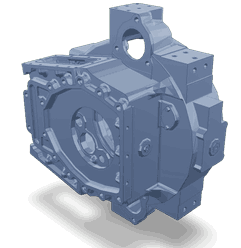

The Flywheel Housing 3102463 by Cummins is a component designed for heavy-duty truck engines. It contributes to efficient engine operation by providing a secure enclosure for the flywheel and related components. This housing is integral to maintaining the balance and performance of the engine, ensuring smooth and reliable operation under demanding conditions.

Basic Concepts of Flywheel Housing

A flywheel housing is a protective casing that encloses the flywheel and other components of the engine’s drive system. Its primary functions include safeguarding the flywheel from external elements, reducing noise, and contributing to the overall balance of the engine. The housing interacts closely with the engine block, transmission, and other drivetrain components, playing a role in the efficient transfer of power and maintaining engine stability 1.

Purpose of the 3102463 Flywheel Housing

The 3102463 Flywheel Housing is specifically designed to enhance the operation of heavy-duty trucks. It contributes to engine balance by securely holding the flywheel in place, which helps in reducing vibrations and ensuring smooth power delivery. Additionally, the housing aids in noise reduction by containing the flywheel and dampening the sound produced during engine operation. Its design also supports overall engine performance by protecting critical components from debris and environmental factors 2.

Key Features

The 3102463 Flywheel Housing boasts several key features that enhance its durability and efficiency. Its robust construction is designed to withstand the rigors of heavy-duty use, while the high-quality materials ensure longevity and reliability. The housing is engineered with precision to fit snugly with other engine components, promoting efficient operation and reducing the likelihood of leaks or failures. Additionally, design elements such as reinforced sections and optimized contours contribute to its strength and performance.

Benefits of Using the 3102463 Flywheel Housing

Utilizing the 3102463 Flywheel Housing offers several advantages. It contributes to improved engine performance by ensuring the flywheel operates within a secure and balanced environment. This results in more efficient power transfer and reduced wear on engine components. Additionally, the housing’s design helps in reducing maintenance needs by protecting internal parts from contaminants and external damage. Enhanced reliability is another benefit, as the robust construction and high-quality materials ensure the housing can endure the stresses of heavy-duty applications.

Installation Process

Proper installation of the 3102463 Flywheel Housing is vital for ensuring optimal performance and longevity. The process involves several steps: first, ensuring the engine is clean and free of debris; second, aligning the housing with the engine block and transmission; third, securing the housing in place using the appropriate fasteners; and finally, conducting a thorough inspection to confirm there are no gaps or misalignments. Best practices include using the correct torque specifications for fasteners and verifying that all connections are tight and secure. Common pitfalls to avoid include over-tightening fasteners, which can lead to damage, and neglecting to check for proper alignment, which can result in performance issues 3.

Troubleshooting Common Issues

Common problems associated with flywheel housings include leaks, cracks, and noise. Leaks can often be traced to improper installation or worn gaskets, and may be addressed by re-sealing or replacing damaged components. Cracks in the housing can result from stress or impact and may require repair or replacement of the housing. Noise issues can arise from loose components or imbalance and may be resolved by inspecting and securing all parts within the housing. Regular inspections and maintenance can help identify and address these issues before they lead to more significant problems.

Maintenance Tips

To ensure the longevity and optimal performance of the 3102463 Flywheel Housing, regular maintenance practices are recommended. This includes periodic inspections for signs of wear, damage, or leaks. Cleaning the housing to remove any buildup of dirt or debris is also important. Additionally, checking and tightening fasteners as needed can help maintain a secure fit and prevent issues such as leaks or noise. Following these maintenance tips can contribute to the reliable operation of the flywheel housing and the overall engine system.

Compatibility and Application

The 3102463 Flywheel Housing is designed for use in specific types of engines and truck models. It is commonly applied in heavy-duty truck engines where robust performance and durability are required. Specific application notes and compatibility information should be consulted to ensure the housing is suitable for the intended engine and vehicle.

Cummins: A Brief Overview

Cummins Inc. is a leading manufacturer in the heavy-duty truck industry, known for its wide range of engine and power solutions. With a history spanning over a century, Cummins has established a reputation for quality, innovation, and reliability. The company offers a diverse product range that includes engines, filtration systems, and aftermarket parts, all designed to meet the demanding needs of heavy-duty applications. Cummins’ commitment to excellence is reflected in its products, which are engineered to deliver performance, efficiency, and durability in various industries.

Cummins Flywheel Housing Part 3102463 Compatibility

The Cummins flywheel housing part number 3102463 is designed to fit a range of Cummins engines, ensuring a secure and efficient connection between the engine and the transmission. This part is integral to the smooth operation of the engine, providing a housing for the flywheel and ensuring proper alignment and function.

ISX15 Series Engines

The flywheel housing part 3102463 is compatible with several ISX15 series engines, including:

- ISX15 CM2250

- ISX15 CM2250 SN

- ISX15 CM2350 X101

These engines are known for their robust performance and reliability, making the flywheel housing a critical component in maintaining their operational integrity.

QSX15 Series Engines

Similarly, the part is also suitable for the following QSX15 series engines:

- QSX15 CM2250 ECF

- QSX15 CM2350 X105

These engines are designed for heavy-duty applications, and the flywheel housing plays a crucial role in ensuring the engine’s durability and efficiency.

X15 Series Engines

The flywheel housing part 3102463 also fits the following X15 series engines:

- X15 CM2350 X116B

- X15 CM2350 X123B

- X15 CM2450 X134B

These engines are engineered for a variety of applications, from construction to transportation, and the flywheel housing is essential for their performance and longevity.

The compatibility of the flywheel housing part 3102463 across these engines underscores its versatility and importance in the Cummins engine lineup.

Role of Part 3102463 Flywheel Housing in Engine Systems

The flywheel housing, identified by part number 3102463, is integral to the operation and efficiency of various engine systems. It serves as a protective enclosure for the flywheel, which is a key component in the engine’s power transmission system.

Integration with Key Engine Components

-

Flywheel and Clutch Assembly: The flywheel housing encases the flywheel, which stores rotational energy and smooths out the power delivery from the engine to the transmission. It also interfaces with the clutch assembly, ensuring a secure and efficient transfer of power.

-

Transmission System: By housing the flywheel, this component plays a direct role in the transmission system. It ensures that the flywheel is properly aligned and protected, allowing for consistent and reliable gear changes.

-

Engine Mounts and Vibration Dampening: The flywheel housing contributes to the overall stability of the engine by providing a solid mounting point for the flywheel. This helps in reducing vibrations and ensuring smooth operation of the engine.

-

Cooling System Interaction: In some engine designs, the flywheel housing may interact with the engine’s cooling system. It can house passages or fins that aid in dissipating heat from the flywheel and surrounding components, contributing to thermal management.

-

Exhaust System: In certain configurations, the flywheel housing may be positioned close to the exhaust manifold. Its design must account for heat management to prevent any adverse effects on the flywheel and clutch operation.

-

Electrical Components: For engines with starter motors that engage directly with the flywheel, the housing must provide adequate clearance and protection. It ensures that the starter motor can operate without interference while safeguarding internal components from damage.

-

Maintenance and Serviceability: The design of the flywheel housing also impacts maintenance procedures. It must allow for easy access to the flywheel and clutch for inspection, repair, or replacement, without requiring extensive disassembly of the engine.

In summary, the flywheel housing (part 3102463) is a multifaceted component that ensures the proper function and protection of the flywheel within the engine system. Its design and integration with other engine components are essential for the overall performance and reliability of the engine.

Conclusion

The 3102463 Flywheel Housing by Cummins is a critical component in heavy-duty truck engines, designed to enhance engine performance, reduce noise, and ensure reliable operation. Its robust construction, precise engineering, and compatibility with various Cummins engines make it a versatile and essential part of the engine system. Proper installation, regular maintenance, and understanding its role within the engine are key to maximizing its benefits and ensuring the longevity of the engine.

-

Quigley, Jon M. SAE International’s Dictionary of Testing, Verification and Validation. SAE International, 2023.

↩ -

Naunheimer, Harald, et al. Automotive Transmissions Fundamentals Selection Design and Application. Springer Vieweg, 2011.

↩ -

General Information, Bulletin Number 4021632, Operation and Maintenance Manual.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.