This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

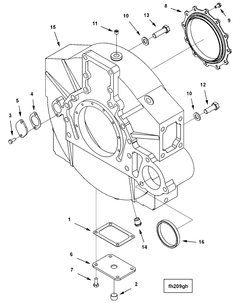

The Cummins 3103894 Flywheel Housing is a component designed to support the operation of commercial trucks. It plays a role in the engine system by providing a secure enclosure for the flywheel, which is integral to the truck’s power transmission and engine balance. Understanding its purpose and significance can help in maintaining and optimizing the performance of commercial trucks.

Basic Concepts of Flywheel Housing

A flywheel housing is a protective casing that encases the flywheel, a heavy rotating disc that stores rotational energy and smooths out the power delivery from the engine. It integrates with the engine block and transmission, ensuring that the flywheel operates within a controlled environment. This housing helps in reducing noise, containing vibrations, and protecting the flywheel from external elements 1.

Purpose of the 3103894 Flywheel Housing

The 3103894 Flywheel Housing is designed to house the flywheel securely, playing a role in the efficient operation of a truck’s engine. It interacts directly with the flywheel, supporting its function in storing rotational energy and balancing the engine’s power output. This housing contributes to engine performance by ensuring the flywheel operates smoothly and efficiently, which is vital for the truck’s overall power delivery and stability 2.

Key Features

The 3103894 Flywheel Housing is characterized by its robust design and the materials used in its construction. It is typically made from durable metals that can withstand high temperatures and mechanical stresses. The housing is designed to fit precisely around the flywheel, ensuring a secure fit and optimal performance. Its design also includes features that facilitate easy installation and maintenance, enhancing its functionality in a commercial truck environment 3.

Benefits

The 3103894 Flywheel Housing offers several benefits, including improved engine efficiency through secure flywheel operation, enhanced durability due to its robust construction, and increased reliability in various operating conditions. These attributes contribute to the overall performance and longevity of the truck’s engine system.

Installation Process

Installing the 3103894 Flywheel Housing involves several steps to ensure it is correctly positioned and secured. The process includes preparing the engine area, aligning the housing with the flywheel, and securing it in place with the appropriate fasteners. It is important to follow manufacturer guidelines to ensure proper installation, which can affect the engine’s performance and the housing’s longevity.

Common Issues and Troubleshooting

Common issues with the 3103894 Flywheel Housing may include misalignment, wear, or damage from external factors. Troubleshooting these problems involves inspecting the housing for signs of damage, ensuring it is correctly aligned with the flywheel, and addressing any wear or corrosion. Regular maintenance and inspections can help identify and resolve these issues before they lead to more significant problems.

Maintenance Tips

To ensure the longevity and optimal performance of the 3103894 Flywheel Housing, regular maintenance is recommended. This includes inspecting the housing for signs of wear or damage, ensuring it is securely fastened, and cleaning it to remove any debris or contaminants. Following these maintenance routines can help prevent issues and ensure the housing continues to support efficient engine operation.

Compatibility and Applications

The 3103894 Flywheel Housing is designed for specific types of trucks and engines, ensuring compatibility and optimal performance. It is commonly used in applications where reliable and efficient engine operation is crucial, contributing to the truck’s overall performance and durability.

Cummins Overview

Cummins Inc. is a leading manufacturer in the commercial truck industry, known for its commitment to quality and innovation. With a history of developing reliable and high-performance engine components, Cummins continues to be a trusted name in the industry, providing solutions that enhance the efficiency and durability of commercial trucks.

Role of Part 3103894 Flywheel Housing in Engine Systems

The flywheel housing, identified by part number 3103894, is an integral component in the assembly and operation of engine systems. It serves as the protective enclosure for the flywheel, which is a key element in the engine’s power transmission system.

Integration with Key Components

-

Flywheel: The primary role of the flywheel housing is to encase the flywheel, safeguarding it from external elements and containing any vibrations produced during engine operation. The flywheel, in turn, stores rotational energy and smooths out the power delivery from the engine’s combustion cycles.

-

Clutch Assembly: The flywheel housing interfaces directly with the clutch assembly. It provides a mounting surface for the pressure plate and facilitates the engagement and disengagement of the clutch. This interaction is essential for the transmission of power from the engine to the transmission system.

-

Torque Converter (in Automatic Transmissions): In engines equipped with automatic transmissions, the flywheel housing interacts with the torque converter. The torque converter uses fluid coupling to transfer engine power to the transmission, and the flywheel housing ensures a secure and vibration-free connection.

-

Engine Block: The flywheel housing is bolted to the engine block, typically at the rear of the engine. This connection is vital for maintaining the structural integrity of the engine and ensuring that all components are aligned correctly.

-

Starter Motor: The flywheel housing also provides a surface for the starter motor to engage with the flywheel’s ring gear. This engagement is necessary for cranking the engine during startup, ensuring smooth and reliable engine ignition.

-

Vibration Dampening: By encapsulating the flywheel, the housing helps in reducing vibrations that could otherwise be transmitted to other engine components. This contributes to the overall smoothness and longevity of the engine’s operation.

-

Sealing and Containment: The housing also plays a role in sealing the flywheel area, preventing contaminants from entering and lubricants from leaking out. This ensures that the flywheel and associated components remain in optimal working condition.

Conclusion

In summary, the flywheel housing (part 3103894) is a multifaceted component that ensures the efficient and reliable operation of the engine by protecting, aligning, and interfacing with several critical engine systems. Regular maintenance and proper installation are key to maximizing its performance and longevity.

-

Berns, K., Dressler, K., Fleischmann, P., Grges, D., Kalmar, R., Sauer, B., Stephan, N., Teutsch, R., & Thul, M. (2018). Proceedings of the 5th Commercial Vehicle Technology Symposium CVT. Springer.

↩ -

Dixon, J. (2010). Modern Diesel Technology Preventive Maintenance and Inspection. Delmar Cengage Learning.

↩ -

Livesey, A. (2000). The Repair of Vehicle Bodies. Elevier.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.