This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

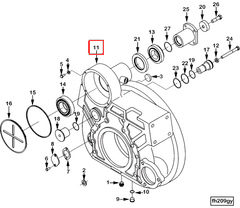

The Cummins 3106132 Flywheel Housing is a component designed to support the flywheel in commercial trucks. It plays a role in ensuring the smooth operation of the engine by providing a secure mounting point for the flywheel and facilitating the transmission of rotational energy from the engine to the transmission system.

Basic Concepts of Flywheel Housing

A flywheel housing is a part of the engine system that encases the flywheel, which is a heavy wheel attached to the crankshaft. Its primary functions include supporting the flywheel, protecting it from external elements, and ensuring the proper alignment of the flywheel with other components such as the clutch and pressure plate. The flywheel housing integrates with the engine block and transmission, playing a role in the efficient transfer of power 1.

Purpose of the 3106132 Flywheel Housing

This Cummins part is specifically designed to support the flywheel in Cummins engines. It facilitates smooth engine operation by providing a stable and secure environment for the flywheel. This housing ensures that the flywheel is correctly aligned with the clutch assembly, which is vital for the efficient transfer of power from the engine to the transmission. Additionally, it helps in reducing vibrations and noise, contributing to a smoother driving experience.

Key Features

This part is constructed from durable materials, typically cast iron or aluminum, which offer excellent strength and resistance to wear. Its design includes precise machining to ensure a perfect fit with the engine block and other components. Unique characteristics such as reinforced mounting points and integrated cooling fins enhance its performance and durability, making it suitable for heavy-duty applications.

Benefits

The use of the 3106132 Flywheel Housing offers several benefits. It contributes to improved engine efficiency by ensuring the flywheel operates within optimal parameters. The housing’s design helps in reducing vibrations, which can lead to a more comfortable driving experience and less wear on other components. Additionally, its durable construction enhances the overall longevity of the engine system 2.

Installation Process

Installing this part involves several steps to ensure proper fitting and function. Preparatory steps include cleaning the mating surfaces on the engine block and transmission to ensure a smooth fit. The necessary tools for installation may include torque wrenches, socket sets, and alignment tools. Best practices involve following the manufacturer’s guidelines for torque specifications and alignment to prevent issues such as leaks or misalignment 3.

Common Issues and Troubleshooting

Common issues with this part may include cracks, leaks, or misalignment. Cracks can occur due to material fatigue or improper installation, while leaks may result from gasket failure or misalignment. Misalignment can lead to inefficient power transfer and increased wear on the clutch system. Troubleshooting steps include visual inspection for cracks, checking gaskets for proper seating, and ensuring all mounting bolts are torqued to the manufacturer’s specifications.

Maintenance Tips

Regular maintenance of the 3106132 Flywheel Housing involves periodic inspection for signs of wear or damage. Cleaning the housing to remove any debris or buildup is also important. If cracks or leaks are detected, prompt repair or replacement is recommended to prevent further damage. Additionally, ensuring that all mounting bolts are tightened to the correct specifications during routine maintenance can help in maintaining the housing’s integrity.

Compatibility and Applications

This part is designed for specific Cummins engine models and is commonly used in various commercial truck applications. Its compatibility ensures that it fits seamlessly with the engine block and transmission, providing reliable performance in heavy-duty environments.

Cummins Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a history spanning over a century, Cummins is renowned for its commitment to quality and innovation in the commercial truck industry. The company’s extensive product range and reputation for durability and performance make it a preferred choice for commercial vehicle manufacturers and operators.

ISM CM876 Flywheel Housing Compatibility

The Flywheel Housing part number 3106132, manufactured by Cummins, is a component that fits seamlessly with the ISM CM876 engine. This part is designed to ensure the smooth operation and longevity of the engine by providing a robust housing for the flywheel.

The ISM CM876 engine, known for its reliability and efficiency, benefits from the precision engineering of the Flywheel Housing part 3106132. This part is specifically engineered to match the ISM CM876’s design, ensuring a perfect fit and optimal performance.

In addition to the ISM CM876, the Flywheel Housing part 3106132 is also compatible with other Cummins engines within the same engine family. This compatibility extends to engines that share similar design and operational characteristics, ensuring that the housing fits securely and functions as intended.

The Flywheel Housing part 3106132 is a testament to Cummins’ commitment to quality and precision, providing a reliable solution for maintaining the integrity and performance of the engine.

Role of Part 3106132 Flywheel Housing in Engine Systems

The Flywheel Housing (part 3106132) is integral to the operation of the Flywheel Top Level Assembly Housing. This component serves as a protective enclosure for the flywheel, which is a key element in the engine’s power transmission system.

When the engine operates, the flywheel stores rotational energy and smooths out the power delivery between the engine’s combustion cycles. The flywheel housing encases this mechanism, ensuring that the flywheel operates within a controlled environment. This housing also interfaces with other critical components such as the clutch assembly and the transmission system.

In the flywheel top-level assembly housing, the flywheel housing aligns precisely with the crankshaft, allowing for efficient transfer of rotational energy. It also provides a mounting point for the flywheel, securing it in place while allowing for the necessary rotational movement. Additionally, the housing facilitates the attachment of the clutch pressure plate, which engages and disengages the flywheel to transmit power to the transmission.

Overall, the flywheel housing plays a role in maintaining the structural integrity and functional efficiency of the flywheel assembly within the engine system.

Conclusion

The 3106132 Flywheel Housing is a critical component in Cummins engines, ensuring the smooth operation and longevity of the engine by providing a robust housing for the flywheel. Its durable construction, precise design, and compatibility with various Cummins engine models make it an essential part for maintaining the integrity and performance of the engine system.

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.