This is an oversize product. Additional shipping fees may apply.

This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

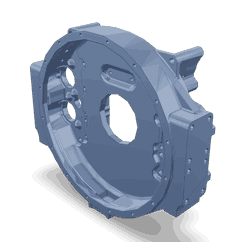

The Cummins 3176637 Flywheel Housing is a vital component in heavy-duty trucks, playing a significant role in the engine system. This part is designed to ensure the efficient operation of the engine by providing a secure enclosure for the flywheel, which is integral to the engine’s functionality.

Basic Concepts of Flywheel Housing

A flywheel housing is a protective casing that encases the flywheel, a heavy rotating disc that stores rotational energy and smooths out the delivery of power from a motor to its load 1. The primary functions of the flywheel housing include protecting the flywheel from external elements, reducing noise, and containing any potential debris that may result from wear or failure. It integrates with other engine components by securing the flywheel in place and ensuring that the rotational energy is efficiently transferred throughout the engine system.

Purpose of the 3176637 Flywheel Housing

The 3176637 Flywheel Housing is specifically engineered to support the flywheel in Cummins engines. It plays a role in the operation of a truck by providing a robust and secure environment for the flywheel. This ensures smooth engine operation by maintaining the flywheel’s alignment and protecting it from damage. The housing also contributes to the overall stability and efficiency of the engine by facilitating the consistent transfer of rotational energy.

Key Features

The 3176637 Flywheel Housing boasts several key features that enhance its performance and reliability. Its durable construction ensures longevity under heavy-duty conditions, while its precise engineering guarantees a perfect fit with Cummins engines. Additionally, the housing is designed to be compatible with various Cummins engine models, making it a versatile component for fleet management and maintenance.

Benefits

The benefits of the 3176637 Flywheel Housing include improved engine performance, enhanced durability, and reliable operation under demanding conditions. By providing a secure and protected environment for the flywheel, this housing contributes to the overall efficiency and stability of the engine. Its robust construction ensures that it can withstand the rigors of heavy-duty use, offering long-term reliability for truck operators.

Installation Process

Installing the 3176637 Flywheel Housing involves several steps to ensure proper fit and function. Begin by preparing the engine area, ensuring that all necessary tools and components are on hand. Carefully align the housing with the engine block and secure it in place using the appropriate fasteners. It is important to follow the manufacturer’s guidelines to ensure that the housing is installed correctly and that all connections are tight and secure. After installation, perform a thorough inspection to confirm that the housing is properly aligned and that there are no leaks or misalignments.

Common Issues and Troubleshooting

Common issues associated with the 3176637 Flywheel Housing may include leaks, cracks, or misalignment. To address these problems, begin by conducting a visual inspection of the housing for any signs of damage or wear. If leaks are detected, check the gaskets and seals for proper installation and condition. Cracks in the housing may require replacement of the part, while misalignment issues can often be resolved by realigning the housing and ensuring that all fasteners are tightened to the manufacturer’s specifications.

Maintenance Tips

To ensure the longevity and optimal performance of the 3176637 Flywheel Housing, regular maintenance is recommended. This includes periodic inspections for signs of wear or damage, cleaning the housing to remove any debris or buildup, and lubricating moving parts as necessary. Following the manufacturer’s maintenance schedule will help prevent issues and ensure that the housing continues to function efficiently.

Cummins Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes a wide range of power solutions, including engines, filtration, and emissions solutions. With a history spanning over a century, Cummins has established a strong reputation in the commercial truck industry for producing reliable and high-performance engines. The company’s commitment to innovation and quality has made it a preferred choice for fleet operators and maintenance professionals worldwide 2.

Role of Part 3176637 Flywheel Housing in Engine Systems

The 3176637 Flywheel Housing is an integral component in the assembly and operation of various engine systems. It serves as the primary mounting point for the flywheel, which is a key element in the engine’s power transmission system 3.

When integrating the flywheel housing with the Engine Block Mounting (EBM) Housing, it ensures a secure and stable connection. This housing is designed to align precisely with the engine block, providing a robust foundation for the flywheel to operate efficiently.

The flywheel itself is mounted within the flywheel housing, and this arrangement is essential for the smooth operation of the engine. The flywheel housing not only supports the flywheel but also helps in managing the rotational energy, which is vital for the engine’s start-stop cycles and overall performance.

Additionally, the flywheel housing interfaces with the Transmission Adapter. This connection is significant as it allows for the seamless transfer of power from the engine to the transmission system. The precision fit between the flywheel housing and the transmission adapter ensures that there is minimal energy loss during this transfer, contributing to the engine’s efficiency and reliability.

Conclusion

In summary, the 3176637 Flywheel Housing plays a significant role in the integration and functionality of the flywheel, EBM Housing, and Transmission Adapter within the engine system. Its design and placement are essential for the effective operation and durability of the engine components it connects.

-

Happian-Smith, Julian. An Introduction to Modern Vehicle Design. Butterworth-Heinemann, 2002.

↩ -

Bartz, Wilfried J. Engine Oils and Automotive Lubrication Mechanical Engineering Book 80. CRC Press, 2019.

↩ -

Hu, Haoran, Simon J Baseley, and Xubin Song. Advanced Hybrid Powertrains for Commercial Vehicles Second Edition. SAE International, 2021.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.