This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

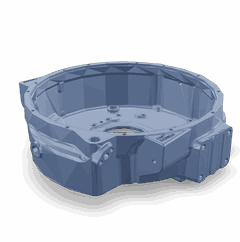

The Flywheel Housing 3352862, manufactured by Cummins, is a significant component in the engine systems of heavy-duty trucks. Cummins, a well-established name in the automotive industry, is renowned for its high-quality engine components designed to enhance performance and reliability. This part is integral to the efficient operation of heavy-duty trucks, ensuring smooth transmission of power and durability under demanding conditions.

Basic Concepts of Flywheel Housing

A flywheel housing is a protective enclosure that houses the flywheel, a key component in the engine’s power transmission system. Its primary functions include safeguarding the flywheel from external elements, facilitating the connection between the engine and transmission, and contributing to the overall stability of the engine system. The flywheel housing integrates with various components such as the clutch, transmission, and engine block, playing a vital role in the seamless operation of these parts 1.

Purpose of Flywheel Housing 3352862

The Flywheel Housing 3352862 is designed to support the flywheel, which stores rotational energy and smooths out the power delivery from the engine to the transmission. This housing ensures that the flywheel operates within a protected environment, reducing the risk of damage from debris or excessive wear. It also plays a role in aligning the flywheel with the clutch and transmission, ensuring efficient power transfer and contributing to the overall performance and reliability of the truck’s engine system.

Key Features

The Flywheel Housing 3352862 boasts several design and construction features that enhance its performance and durability. These include a robust material composition that resists wear and corrosion, precise engineering to ensure a perfect fit with the flywheel and other components, and a design that facilitates easy installation and maintenance. These features contribute to the housing’s ability to withstand the rigors of heavy-duty truck operation.

Benefits

The advantages provided by the Flywheel Housing 3352862 include improved engine efficiency through reliable power transmission, reduced wear on connected components due to its protective function, and enhanced overall performance of the truck’s engine system. Its durable construction also contributes to the longevity of the flywheel and associated components, offering cost-effective maintenance over the vehicle’s lifespan.

Installation Process

Proper installation of the Flywheel Housing 3352862 involves several steps to ensure it functions correctly within the engine system. The process includes preparing the engine block, aligning the housing with the flywheel and transmission, securing it in place with the appropriate fasteners, and verifying the alignment and fit. Necessary tools for this procedure include torque wrenches, alignment tools, and possibly a flywheel alignment tool, depending on the specific truck model. Precautions include ensuring the engine is cool before beginning work and following the manufacturer’s guidelines for torque specifications and alignment.

Common Issues and Troubleshooting

Typical problems associated with flywheel housings can include misalignment, wear, or damage from external elements. Potential causes range from improper installation to operational stress or environmental factors. Recommended troubleshooting steps involve inspecting the housing for signs of wear or damage, checking the alignment with the flywheel and transmission, and ensuring all fasteners are securely tightened to the manufacturer’s specifications. Addressing these issues promptly can prevent more significant problems and ensure the continued efficient operation of the truck’s engine system.

Maintenance Tips

Regular maintenance practices for the Flywheel Housing 3352862 include inspecting it for signs of wear or damage during routine engine checks, ensuring all fasteners are tight, and cleaning the housing to remove any debris that could cause abrasion or interference with its function. Following the manufacturer’s recommended maintenance schedule and guidelines can help ensure the longevity and optimal performance of the flywheel housing and the engine system as a whole.

Cummins Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a history spanning over a century, Cummins has established a strong reputation for quality, reliability, and customer satisfaction in the automotive industry. Its product range includes engines and components for heavy-duty trucks, among other applications, demonstrating a commitment to innovation and excellence in engine technology. Cummins’ components are known for their durability, efficiency, and performance, making them a preferred choice for professionals in the automotive and heavy-duty truck sectors.

Compatibility of Flywheel Housing 3352862

The Flywheel Housing 3352862 is designed to interface with several Cummins engine models, ensuring smooth operation and efficient power transfer. This part is engineered to work seamlessly with the following engines:

6C8.3 Engine Series

The 6C8.3 engine series benefits from the robust design of the Flywheel Housing 3352862. This housing is engineered to withstand the rigors of heavy-duty applications, providing a stable platform for the flywheel and ensuring that the engine’s rotational components operate without undue stress. The compatibility of this part with the 6C8.3 series underscores its versatility and reliability in demanding environments.

Other Compatible Engines

While the primary focus here is on the 6C8.3 series, it is important to note that the Flywheel Housing 3352862 is also compatible with other Cummins engines. This part’s design allows it to fit various engine configurations, making it a versatile choice for maintenance and repair across multiple models. The housing’s precision engineering ensures that it meets the specific requirements of each engine type, providing a secure and efficient connection between the flywheel and the engine block.

Role of Flywheel Housing 3352862 in Engine Systems

The flywheel housing, identified by part number 3352862, is an integral component in the operation of engine systems. It serves as the enclosure for the flywheel, which is a heavy rotating disc that stores rotational energy and smooths out the delivery of power from a motor to its load.

When the engine’s pistons move, they create rotational force that is transferred to the flywheel via the crankshaft. The flywheel housing encases this flywheel, providing a secure and stable environment for it to operate within. This housing is typically bolted to the engine block and transmission, ensuring a rigid connection that minimizes vibrations and maintains alignment.

Moreover, the flywheel housing is designed to accommodate the clutch assembly, which is essential for transmitting power from the engine to the transmission. Within this housing, the pressure plate, clutch disc, and release bearing are housed, allowing for the engagement and disengagement of the clutch. This is vital for smooth gear changes and efficient power transfer.

Additionally, the flywheel housing often includes provisions for mounting the starter motor. The starter motor engages with the flywheel’s ring gear to crank the engine during startup. The housing must be robust enough to withstand the forces generated during this process.

In summary, the Flywheel Housing 3352862 plays a significant role in maintaining the structural integrity and functional efficiency of the engine system. It ensures the proper operation of the flywheel, clutch assembly, and starter motor, contributing to the overall performance and reliability of the engine.

Conclusion

The Flywheel Housing 3352862 is a critical component in the engine systems of heavy-duty trucks, designed to enhance performance and reliability. Its robust construction, precise engineering, and compatibility with various Cummins engines make it a versatile and dependable choice for professionals in the automotive and heavy-duty truck sectors. Proper installation, maintenance, and troubleshooting are essential to ensure the longevity and optimal performance of this part, contributing to the overall efficiency and reliability of the engine system.

-

Reif, Konrad, ed. Gasoline Engine Management Systems and Components. Springer Vieweg, 2015.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.