This is an oversize product. Additional shipping fees may apply.

This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

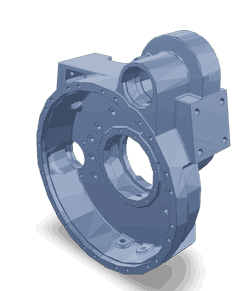

The Cummins 3899975 Flywheel Housing is a component designed for use in heavy-duty trucks. It serves a significant role in the operation of these vehicles by providing a secure mounting point for the flywheel and facilitating the transfer of power from the engine to the transmission. Understanding its purpose and functionality is key to maintaining the efficiency and reliability of heavy-duty truck engines.

Basic Concepts of Flywheel Housing

A Flywheel Housing is an integral part of a truck’s engine system. Its primary functions include enclosing the flywheel, providing a mounting surface for the transmission, and contributing to the structural integrity of the engine assembly. The housing works in conjunction with the flywheel to smooth out the power delivery from the engine, ensuring consistent operation despite the inherent fluctuations in power output during the combustion cycle 1.

Purpose of the 3899975 Flywheel Housing

The 3899975 Flywheel Housing plays a role in the operation of a truck by securely attaching the flywheel to the engine block. This connection is vital for the transmission of rotational force from the engine to the transmission system. The housing also helps in dampening vibrations produced by the engine, contributing to a smoother operation and reducing wear on connected components 2.

Key Features

The design and construction of the 3899975 Flywheel Housing incorporate several features that enhance its functionality. It is typically made from durable materials such as cast iron or aluminum, chosen for their strength and resistance to wear. The housing is engineered to provide a precise fit with the engine block and transmission, ensuring optimal performance and longevity. Its design may also include features for improved heat dissipation and vibration damping 3.

Benefits

The advantages provided by the 3899975 Flywheel Housing include improved engine efficiency through reduced friction and enhanced power transmission. Its durable construction contributes to the overall reliability of the engine system, while its design helps in minimizing vibrations, leading to a smoother operation of the vehicle 4.

Installation Process

Proper installation of the 3899975 Flywheel Housing involves several steps. It begins with ensuring the engine block is clean and free of any debris. The housing should be aligned correctly with the engine and transmission before being secured in place. Tools required may include torque wrenches for tightening bolts to the manufacturer’s specifications, ensuring a secure and proper fit 5.

Maintenance and Troubleshooting

Maintaining the 3899975 Flywheel Housing involves regular inspections for signs of wear or damage. Common issues may include cracks in the housing or excessive wear on the mounting surfaces. Troubleshooting tips include checking for proper alignment and securing of the housing, as well as ensuring that all bolts are tightened to the correct specifications to prevent loosening over time 6.

Compatibility and Applications

The 3899975 Flywheel Housing is designed for specific types of engines and truck models. Its applications in the industry are notable for enhancing the performance and reliability of heavy-duty trucks. Detailed information on compatibility and specific applications will be provided separately to ensure accurate installation and use 7.

Cummins Corporation Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes a wide range of power solutions. With a history spanning over a century, Cummins has established a reputation for quality and innovation in the automotive and heavy-duty truck industry. Its product range includes engines, filtration systems, and other components designed to enhance the performance and efficiency of vehicles 8.

Integration of Part 3899975 Flywheel Housing with Engine Systems

The 3899975 Flywheel Housing is an essential component in the assembly and operation of the flywheel system within an engine. Its primary function is to encase and support the flywheel, which is a key element in the engine’s power transmission system.

Flywheel Top-Level Assembly Housing

In the flywheel top-level assembly housing, the 3899975 Flywheel Housing acts as the foundational structure. It securely holds the flywheel in place, ensuring that it is correctly aligned with the engine’s crankshaft. This alignment is vital for the efficient transfer of rotational energy from the engine to the transmission system. The housing also provides a stable environment for the flywheel to operate, minimizing vibrations and ensuring smooth engine performance 9.

Housing

As a part of the broader housing system, the 3899975 Flywheel Housing contributes to the overall integrity and stability of the engine’s mechanical components. It interfaces with other housing components, such as the bell housing, to create a cohesive unit that supports the flywheel’s function. This integration is important for maintaining the precision and reliability of the engine’s power delivery 10.

Flywheel

Directly interacting with the flywheel, the 3899975 Flywheel Housing plays a significant role in the flywheel’s operation. The housing must be designed to accommodate the flywheel’s size and weight, ensuring that it can withstand the forces generated during engine operation. It also facilitates the connection between the flywheel and the clutch system, which is essential for the engagement and disengagement of the engine’s power to the transmission 11.

Conclusion

In summary, the 3899975 Flywheel Housing is a key component in the assembly and functionality of the flywheel system. Its role in supporting and aligning the flywheel, integrating with other housing components, and facilitating the connection to the clutch system underscores its importance in the engine’s overall performance.

-

Saiful Bari, Diesel Engine Combustion, Emissions and Condition Monitoring, InTech, 2013.

↩ -

Julian Happian-Smith, An Introduction to Modern Vehicle Design, Butterworth-Heinemann, 2002.

↩ -

Paul Dempsey, Troubleshooting and Repairing Diesel Engines, 5th Edition, McGraw-Hill, 2018.

↩ -

Ed Sobey, A Field Guide to Automotive Technology, Chicago Review Press, 2009.

↩ -

Cummins Inc., ISB6.7 G CM2180 B118, Service Manual (5411104).

↩ -

Cummins Inc., ISB6.7 G CM2180 B118, Service Manual (5411104).

↩ -

Cummins Inc., ISB6.7 G CM2180 B118, Service Manual (5411104).

↩ -

Cummins Inc., ISB6.7 G CM2180 B118, Service Manual (5411104).

↩ -

Cummins Inc., ISB6.7 G CM2180 B118, Service Manual (5411104).

↩ -

Cummins Inc., ISB6.7 G CM2180 B118, Service Manual (5411104).

↩ -

Cummins Inc., ISB6.7 G CM2180 B118, Service Manual (5411104).

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.