This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

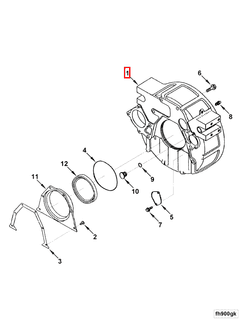

The Cummins 3904717 Flywheel Housing is a component designed for use in commercial trucks. It plays a significant role in the operation of these vehicles by housing the flywheel and interacting with the clutch system. Understanding its purpose and functionality is key to maintaining the efficiency and reliability of truck engines.

Basic Concepts of Flywheel Housing

A flywheel housing is an enclosure that protects the flywheel, a heavy rotating disc that stores rotational energy and smooths out the delivery of power from a motor to its load. In the engine system, the flywheel housing not only safeguards the flywheel but also ensures proper alignment and operation of the clutch. It interfaces with other components such as the flywheel and clutch, playing a role in the transmission of power from the engine to the drivetrain 1.

Purpose of the 3904717 Flywheel Housing

This Cummins part is integral to the operation of a truck. It contributes to maintaining engine balance by securely holding the flywheel in place. This housing facilitates smooth power transmission from the engine to the transmission system, ensuring that the rotational energy is efficiently transferred and utilized.

Key Features

The design and construction of the 3904717 incorporate several features that enhance its performance. It is typically made from durable materials that can withstand the high stresses and temperatures of engine operation. The housing is engineered for structural integrity, ensuring it can maintain its shape and function under demanding conditions. Unique design elements may include precision machining for tight tolerances and robust mounting points for secure attachment to the engine.

Benefits

The 3904717 offers several advantages. It contributes to improved engine efficiency by ensuring that the flywheel operates within the designed parameters. The housing’s durability allows it to withstand the rigors of heavy-duty applications, providing long-term reliability. Its design also enhances the overall performance of the engine by facilitating a smooth and consistent power delivery.

Installation Process

Installing the 3904717 requires careful attention to detail. Preparatory steps include ensuring the engine and surrounding components are clean and free of debris. The necessary tools for installation may vary, but typically include torque wrenches and alignment tools. Best practices involve following the manufacturer’s guidelines for torque specifications and alignment to ensure a secure fit and proper function.

Common Issues and Troubleshooting

Typical problems with the 3904717 may include leaks, cracks, or misalignment. These issues can often be identified through visual inspection or by monitoring the performance of the clutch system. Troubleshooting methods may involve repairing or replacing damaged components, ensuring proper alignment, and verifying that all connections are secure.

Maintenance Tips

Regular maintenance of the 3904717 is important for prolonging its lifespan. This includes routine inspections for signs of wear or damage, cleaning to remove any buildup that could affect performance, and following the manufacturer’s recommendations for when to consider replacement. Proper maintenance helps ensure the housing continues to function effectively within the engine system.

Manufacturer Overview - Cummins

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a strong reputation in the automotive industry, Cummins is known for its commitment to producing high-quality engine components. The company’s history of innovation and excellence underscores its position as a trusted provider of engine technology for commercial applications.

Cummins Flywheel Housing Part 3904717 Compatibility

The Cummins flywheel housing part number 3904717 is designed to fit a variety of Cummins engines, ensuring a secure and efficient connection between the engine and the transmission. This part is critical for maintaining the integrity of the engine’s rotational system and is compatible with the following engine models:

- 4B3.9

- 6B5.9

- B5.9 G

- B5.9 GAS PLUS CM556

- ISB CM550

- QSB5.9 44 CM550

For the B5.9 G and B5.9 GAS PLUS CM556 engines, the flywheel housing part 3904717 ensures a precise fit, facilitating smooth power transfer and reducing the risk of mechanical failure.

Similarly, for the ISB CM550 and QSB5.9 44 CM550 engines, this part provides a robust connection, enhancing the overall performance and longevity of the engine.

The compatibility of the flywheel housing part 3904717 with these engines underscores its versatility and importance in maintaining the operational efficiency of Cummins engines.

Role of Part 3904717 Flywheel Housing in Engine Systems

The flywheel housing, specifically part 3904717, is integral to the operation of engine systems by providing a secure enclosure for the flywheel. This housing is designed to interface with several key components to ensure efficient and reliable engine performance.

Integration with the Flywheel

The primary function of the flywheel housing is to encase the flywheel, which is a heavy, rotating disc that stores rotational energy. The flywheel housing protects the flywheel from external elements and ensures that it operates within a controlled environment. The housing is precisely machined to fit the flywheel snugly, minimizing vibrations and ensuring smooth operation.

Connection to the Clutch Assembly

In manual transmission vehicles, the flywheel housing is directly connected to the clutch assembly. The housing provides a mounting surface for the pressure plate, which is part of the clutch system. The pressure plate applies force to the friction disc, enabling the transmission of power from the engine to the transmission. The flywheel housing ensures that the clutch components are aligned correctly, which is essential for smooth gear changes and efficient power transfer.

Interaction with the Engine Block

The flywheel housing is bolted to the rear of the engine block. This connection is vital for maintaining the structural integrity of the engine. The housing must be robust enough to withstand the torque and vibrations generated by the engine. Proper alignment and secure fastening of the housing to the engine block are necessary to prevent leaks and ensure the longevity of the engine components.

Relationship with the Starter Motor

The flywheel housing also plays a role in the starting mechanism of the engine. The starter motor engages with the flywheel through the starter ring gear, which is often part of the flywheel assembly. The housing provides the necessary space and protection for this interaction, ensuring that the starter motor can engage the flywheel without interference.

Contribution to Vibration Dampening

One of the less obvious but important roles of the flywheel housing is in vibration dampening. By enclosing the flywheel, the housing helps to contain and manage the vibrations produced during engine operation. This contributes to a smoother running engine and reduces wear on connected components.

Support for Ancillary Components

The flywheel housing may also serve as a mounting point for other engine components, such as the exhaust manifold or various sensors. Its sturdy construction makes it an ideal location for securing these parts, ensuring they remain in place and function correctly.

Conclusion

In summary, the 3904717 flywheel housing is a multifaceted component that interacts with several critical engine systems. Its role in protecting the flywheel, supporting the clutch assembly, connecting to the engine block, facilitating the starter motor engagement, dampening vibrations, and providing support for ancillary components underscores its importance in the overall functionality of the engine.

-

Majewski, Addy, and Hannu Jaskelainen. Diesel Emissions and Their Control: Second Edition. SAE International, 2023.

↩

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.