This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

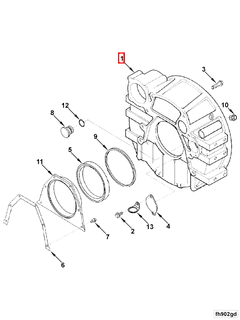

The Cummins 3914004 Flywheel Housing is a component designed for use in commercial trucks. It plays a significant role in the operation of these vehicles by providing a secure mounting point for the flywheel, which is a part of the engine’s power transmission system. This housing ensures the flywheel is correctly positioned and supported, contributing to the overall efficiency and performance of the truck’s engine.

Basic Concepts of Flywheel Housing

Flywheel housings are integral to the engine system, primarily functioning to enclose and support the flywheel. The flywheel, in turn, plays a role in storing rotational energy and smoothing out the power delivery from the engine’s combustion cycles 1. The housing protects the flywheel from external elements and ensures it remains aligned with the engine’s crankshaft. This alignment is vital for the efficient transfer of power from the engine to the transmission system.

Purpose of the Cummins 3914004 Flywheel Housing

The Cummins 3914004 Flywheel Housing is designed to enhance the operation of a truck by securely holding the flywheel in place. This secure mounting allows for consistent and reliable power transmission from the engine to the drivetrain. By maintaining the flywheel’s position and alignment, the housing contributes to the engine’s stability and efficiency, ensuring that the truck operates smoothly under various conditions.

Key Features

The Cummins 3914004 Flywheel Housing is characterized by its robust design and the use of high-quality materials. These features ensure durability and reliability in demanding commercial truck applications. The housing is engineered to withstand the high stresses and vibrations associated with heavy-duty engine operations. Additionally, its design may include features that facilitate easier installation and maintenance, such as alignment dowels or integrated mounting points.

Benefits

The use of the Cummins 3914004 Flywheel Housing offers several advantages. It contributes to improved engine stability by ensuring the flywheel is securely mounted. This stability can lead to enhanced engine performance and efficiency. Furthermore, by reducing the risk of flywheel misalignment or damage, the housing can potentially lead to cost savings for fleet operators through reduced maintenance and repair needs.

Installation Process

Installing the Cummins 3914004 Flywheel Housing requires careful attention to detail to ensure proper alignment and secure mounting. The process involves preparing the engine block, positioning the housing over the flywheel, and securing it in place with the appropriate fasteners. It is important to follow manufacturer guidelines for torque specifications and sequence to ensure the housing is properly installed. Additionally, verifying the alignment of the flywheel with the crankshaft is crucial for optimal engine performance.

Maintenance Tips

To ensure the Cummins 3914004 Flywheel Housing continues to perform optimally, regular maintenance is recommended. This includes inspecting the housing for signs of wear or damage, ensuring all fasteners are tight, and cleaning the housing to remove any debris or contaminants. Regular maintenance can help identify potential issues before they lead to more significant problems, contributing to the longevity and reliability of the component.

Troubleshooting Common Issues

Common issues with the Cummins 3914004 Flywheel Housing may include misalignment, wear, or damage to the housing or flywheel. These problems can manifest as unusual engine vibrations, difficulty starting the engine, or decreased performance. Addressing these issues may involve realigning the flywheel, replacing worn or damaged components, or performing a thorough inspection of the housing and related parts to identify the root cause of the problem.

Compatibility and Applications

The Cummins 3914004 Flywheel Housing is designed for specific applications within the commercial truck industry. It is compatible with certain Cummins engine models, providing a secure and efficient solution for flywheel mounting in these applications. Understanding the specific compatibility and applications of this housing is important for ensuring it is used in the correct engine and truck configurations.

Cummins Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a history spanning over a century, Cummins has established a reputation for quality, reliability, and innovation in the commercial truck industry. The company’s product range includes a variety of engines and components designed to meet the demanding requirements of commercial and industrial applications.

Role of Part 3914004 Flywheel and Flywheel Housing in Engine Systems

In the orchestration of engine systems, the flywheel and its housing are indispensable components that work in harmony with other elements to ensure optimal performance. The flywheel, a heavy rotating disc, is attached to the crankshaft and plays a significant role in storing rotational energy. This stored energy smooths out the power delivery from the engine’s combustion cycles, contributing to a consistent rotational speed 1.

The flywheel housing, which encases the flywheel, provides a secure environment for the flywheel to operate. It is designed to protect the flywheel from external elements and to maintain the integrity of the engine’s rotating assembly.

When the engine is running, the flywheel’s inertia helps to keep the crankshaft rotating between power strokes, which is essential for the operation of the valve train. The valve train, consisting of components like the camshaft, lifters, pushrods, and rocker arms, relies on the consistent rotation of the crankshaft to open and close the engine’s valves at the correct times.

The flywheel also interacts with the clutch system in manual transmissions. As the driver engages the clutch, the flywheel is connected to the transmission input shaft, allowing the engine’s power to be transmitted to the drivetrain. In automatic transmissions, the torque converter takes the place of the clutch, but the flywheel still plays a role in maintaining engine smoothness 2.

Furthermore, the flywheel housing must be precisely aligned with the engine block to ensure that the flywheel operates within the correct clearances. This alignment is vital for the proper function of the starter motor, which engages with the flywheel to crank the engine during startup.

In summary, the flywheel and its housing are integral to the engine’s operation, working in concert with the crankshaft, valve train, clutch or torque converter, and starter motor to deliver a smooth and reliable power output.

Conclusion

The Cummins 3914004 Flywheel Housing is a critical component in the operation of commercial trucks, ensuring the flywheel is securely mounted and aligned. Its robust design and high-quality materials contribute to the engine’s stability, efficiency, and longevity. Proper installation, regular maintenance, and understanding its compatibility with specific engine models are essential for optimal performance and reliability.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.