This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

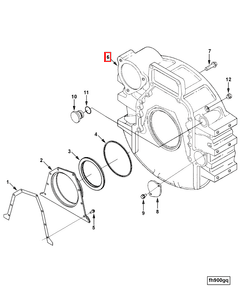

The Flywheel Housing part #3928490, manufactured by Cummins, is a critical component in the operation of heavy-duty truck engines. It ensures efficient power transmission and smooth engine operation within the powertrain system.

Basic Concepts of Flywheel Housing

A flywheel housing is a protective enclosure that houses the flywheel, a key component in the engine’s power transmission system. Its primary functions include safeguarding the flywheel from external elements, facilitating the connection between the engine and transmission, and contributing to the overall stability of the powertrain. Flywheel housings are commonly constructed from durable materials such as cast iron or aluminum, chosen for their strength, heat resistance, and ability to dampen vibrations 1.

Purpose of the 3928490 Flywheel Housing

The 3928490 Flywheel Housing is designed to encase the flywheel securely, playing a role in the engine’s operation by providing a stable mounting point for the flywheel. This housing contributes to smooth engine operation by ensuring precise alignment between the engine and transmission. Additionally, it aids in the efficient transfer of power from the engine to the transmission, enhancing the truck’s performance 2.

Key Features

The 3928490 Flywheel Housing boasts several key features that enhance its performance and durability. Its design incorporates precise engineering to ensure a snug fit around the flywheel, minimizing the risk of misalignment. Constructed from high-quality materials, it offers excellent resistance to wear and corrosion, ensuring longevity in demanding operating conditions. Additionally, the housing may feature integrated mounting points for accessories, further enhancing its versatility and functionality 3.

Benefits

The 3928490 Flywheel Housing offers several benefits that contribute to overall truck performance and reliability. By providing a secure enclosure for the flywheel, it helps reduce vibration and noise, leading to a smoother driving experience. Its robust construction enhances engine efficiency by ensuring precise power transmission, while its durability minimizes the need for frequent replacements, reducing maintenance costs over time 4.

Installation Process

Installing the 3928490 Flywheel Housing requires careful attention to detail to ensure proper fitment and functionality. Begin by preparing the engine bay, ensuring that all necessary tools and components are readily available. Follow the manufacturer’s instructions for removing the old flywheel housing and installing the new one, taking care to align it correctly with the engine and transmission. Use appropriate fasteners and torque specifications to secure the housing in place, and perform a thorough inspection to verify proper installation 5.

Common Issues and Troubleshooting

Despite its robust construction, the 3928490 Flywheel Housing may encounter common issues such as cracks, leaks, or misalignment over time. Regular inspection and maintenance can help identify these issues early, allowing for timely repairs or replacements. In the event of cracks or leaks, assess the extent of the damage and determine whether repair or replacement is necessary. Misalignment issues may require re-alignment or adjustment of the housing to ensure proper operation 6.

Maintenance Tips

To ensure the longevity and optimal performance of the 3928490 Flywheel Housing, routine maintenance practices are essential. Regularly inspect the housing for signs of wear, corrosion, or damage, and address any issues promptly to prevent further deterioration. Follow the manufacturer’s recommended maintenance schedule for inspections and replacements, and keep the housing clean and free from debris to prevent buildup and contamination 7.

Cummins Overview

Cummins Inc. is a renowned manufacturer with a rich history of producing high-quality engine components for the automotive industry. Known for its commitment to quality and innovation, Cummins offers a wide range of products designed to meet the demanding needs of heavy-duty applications. With a reputation for reliability and performance, Cummins continues to be a trusted name in the industry, providing customers with durable and efficient engine solutions 8.

Role of Part 3928490 Flywheel Housing in Engine Systems

The flywheel housing, specifically part 3928490, is an integral component in the assembly and operation of engine systems. It serves as the protective enclosure for the flywheel, which is a heavy rotating disc that stores rotational energy and smooths out the delivery of power from a motor to the transmission.

Integration with Key Components

-

Flywheel: The primary role of the flywheel housing is to encase the flywheel, ensuring it operates within a controlled environment. This housing protects the flywheel from external elements and contains any potential debris that may result from wear and tear.

-

Clutch Assembly: The flywheel housing interfaces directly with the clutch assembly. It provides a mounting surface for the pressure plate, which is a critical component of the clutch system. The pressure plate applies force to the friction disc, enabling the transfer of power from the engine to the transmission.

-

Transmission Bell Housing: The flywheel housing aligns with the transmission bell housing, forming a sealed connection between the engine and transmission. This alignment ensures that the rotational forces are efficiently transmitted without loss of power or introduction of vibrations.

-

Engine Block: The housing is bolted to the engine block, securing the flywheel in place. This connection is vital for maintaining the structural integrity of the engine system and ensuring that all components operate in unison.

-

Starter Motor: The flywheel housing also provides a surface for the starter motor to engage with the flywheel. During engine start-up, the starter motor turns the flywheel, which in turn cranks the engine.

-

Vibration Dampener: In some engine configurations, the flywheel housing may incorporate a vibration dampener. This component helps to reduce the vibrations transmitted from the engine to the rest of the vehicle, enhancing overall smoothness and durability.

Functional Synergy

The flywheel housing works in concert with these components to ensure the engine operates smoothly and efficiently. By providing a secure and protected environment for the flywheel, it allows for consistent power delivery and reliable operation of the clutch system. The precise alignment and secure mounting facilitate the efficient transfer of rotational energy from the engine to the transmission, ultimately contributing to the vehicle’s performance and drivability.

Conclusion

The 3928490 Flywheel Housing is a critical component in the operation of heavy-duty truck engines, ensuring efficient power transmission and smooth engine operation. Its robust construction, precise engineering, and integration with key engine components contribute to overall truck performance and reliability. Regular maintenance and timely troubleshooting are essential to ensure the longevity and optimal performance of this Cummins part.

-

Composite Materials Handbook Volume 4 Metal Matrix Composites, SAE International, 2013

↩ -

Engine Testing: Theory and Practice: Third Edition, A.J. Martyr, SAE International, 2007

↩ -

Controlling Noise and Vibration in Road Vehicles, Matthew Harrison, SAE International, 2004

↩ -

Offroad Vehicle Dynamics Analysis Modelling and Optimization, Hamid Taghavifar and Aref Mardani, Springer, 2017

↩ -

PowerGen QSX15 CM2250 ECF, Bulletin Number 4310663, Operation and Maintenance Manual

↩ -

Composite Materials Handbook Volume 4 Metal Matrix Composites, SAE International, 2013

↩ -

Engine Testing: Theory and Practice: Third Edition, A.J. Martyr, SAE International, 2007

↩ -

Controlling Noise and Vibration in Road Vehicles, Matthew Harrison, SAE International, 2004

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.