This is an oversize product. Additional shipping fees may apply.

This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

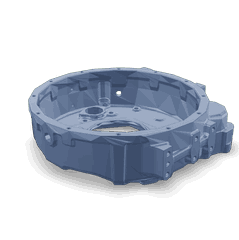

The Cummins 5272408 Flywheel Housing is a critical component for commercial trucks, designed to provide a secure and stable environment for the flywheel, clutch, and transmission. Understanding its purpose and significance is essential for maintaining and optimizing the performance of these vehicles 1.

Basic Concepts of Flywheel Housing

A flywheel housing is a protective enclosure that houses the flywheel, a vital part of the engine’s power transmission system. Its primary functions include safeguarding the flywheel from external elements, ensuring proper alignment with the clutch and transmission, and contributing to the overall stability of the powertrain 2.

Purpose of the 5272408 Flywheel Housing

This Cummins part plays a significant role in the operation of a truck by securely holding the flywheel in place. It interacts with the flywheel to maintain rotational stability, with the clutch to ensure smooth engagement and disengagement of power, and with the transmission to facilitate the transfer of power from the engine to the drivetrain 3.

Key Features

The design and construction of the 5272408 incorporate several features that enhance its functionality and durability. It is typically made from high-strength materials to withstand heavy-duty applications. The housing is engineered to provide structural integrity, ensuring it can support the flywheel and clutch under high torque conditions. Unique design elements may include precision machining for accurate fitment and robust mounting points for secure attachment to the engine block.

Benefits

The 5272408 offers several advantages, including improved durability due to its robust construction, enhanced performance through precise engineering, and reliability in heavy-duty applications. These benefits contribute to the overall efficiency and longevity of the truck’s powertrain, reducing the likelihood of failures and the need for frequent repairs.

Installation Process

Proper installation of the 5272408 involves several steps to ensure it is correctly positioned and secured. Prerequisites include ensuring the engine block is clean and free of debris. Tools required may include torque wrenches for tightening bolts to the manufacturer’s specifications, alignment tools to ensure proper positioning, and possibly a flywheel alignment tool to guarantee the flywheel is correctly seated. Following the manufacturer’s guidelines during installation is crucial for optimal performance and longevity.

Common Issues and Troubleshooting

Typical problems associated with flywheel housings can include misalignment, wear, and damage from external impacts. Diagnostic methods involve visual inspection for signs of wear or damage, checking alignment with the clutch and transmission, and ensuring all mounting bolts are properly torqued. Potential solutions may include realigning components, replacing worn or damaged parts, and ensuring all connections are secure.

Maintenance Tips

Regular maintenance practices for the 5272408 include periodic inspection for signs of wear, ensuring all bolts are tightened to the correct specifications, and cleaning the housing to remove any debris that could affect performance. Inspection intervals should be in accordance with the manufacturer’s recommendations or based on the operating conditions of the truck. Proper care procedures will help maintain the efficiency and reliability of the flywheel housing.

Cummins Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes a wide range of power solutions, including engines, filtration, and related technologies. With a history of innovation and a strong reputation in the commercial truck industry, Cummins products are known for their reliability, performance, and durability. The company’s extensive product range serves various industries, providing solutions that meet the demanding requirements of heavy-duty applications.

Role of 5272408 Flywheel Housing in Engine Systems

The 5272408 is an integral component in the operation of engine systems, serving as the protective enclosure for the flywheel. This housing is designed to secure the flywheel in place while allowing it to rotate freely, which is essential for the smooth transfer of power from the engine to the transmission.

When the engine’s pistons move, they generate rotational force that is transferred to the crankshaft. The flywheel, attached to the crankshaft, stores this rotational energy and smooths out the power delivery to the transmission. The flywheel housing ensures that the flywheel is correctly aligned and protected from external elements that could interfere with its operation.

Additionally, the flywheel housing plays a role in the operation of the clutch system. It provides a mounting surface for the pressure plate and clutch disc, which are essential components for engaging and disengaging the engine from the transmission. The housing must be robust enough to withstand the forces generated during clutch engagement and disengagement.

Furthermore, the flywheel housing often incorporates features for the starter motor engagement. A ring gear is typically attached to the outside of the flywheel, and the housing must allow the starter motor’s pinion gear to mesh with this ring gear to start the engine.

Conclusion

In summary, the 5272408 Flywheel Housing is a key component that ensures the proper function and protection of the flywheel, clutch system, and starter motor engagement within engine systems. Its robust construction, precise engineering, and integration with other engine components contribute to the overall efficiency and reliability of commercial trucks.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.