This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

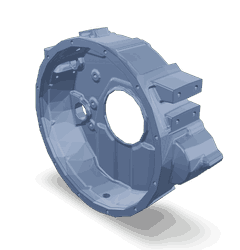

The Cummins 5288315 Flywheel Housing is a critical component designed for heavy-duty trucks. It ensures a secure mounting point for the flywheel and facilitates the interaction between the engine and transmission, contributing to the vehicle’s performance and reliability 1.

Basic Concepts of Flywheel Housing

A flywheel housing is essential for the engine system, designed to encase the flywheel. It supports the flywheel and clutch assembly, ensuring alignment and secure placement. The housing interacts with the flywheel, clutch, and transmission, maintaining structural integrity and aiding in the smooth operation of the clutch mechanism 2.

Purpose of the 5288315 Flywheel Housing

The 5288315 Flywheel Housing is engineered to enhance the operation of heavy-duty trucks. It ensures the flywheel and clutch operate within a precisely aligned and protected environment, reducing vibrations and maintaining stability during power transmission 3.

Key Features

This part boasts several key features that enhance its functionality and durability. It is constructed from high-quality materials to withstand heavy-duty use. The design ensures optimal alignment and fit within the engine system, with robust mounting points and secure attachment mechanisms to maintain stability under high torque conditions 4.

Benefits

Installing the 5288315 Flywheel Housing offers several benefits. It provides a solid foundation for the flywheel and clutch assembly, enhancing engine stability. Precise alignment reduces wear on clutch components, and the housing protects related components from excessive vibrations and misalignment, increasing their longevity 5.

Installation Process

Installing this Cummins part requires careful attention to detail. Ensure the engine is cool and the vehicle is securely supported. Disconnect the battery to prevent electrical issues. Remove the old flywheel housing, noting any gaskets or seals that need replacement. Position the new housing, ensuring correct alignment with the engine and transmission. Secure it with appropriate fasteners and reconnect any electrical connections or hoses. Perform a thorough inspection before restarting the engine 6.

Troubleshooting Common Issues

Common issues with flywheel housings include leaks, misalignment, or excessive wear. Identify symptoms such as unusual noises, vibrations, or fluid leaks. Inspect the housing for damage or wear, ensure all fasteners are tight, and check for proper alignment. If leaks are present, inspect and replace damaged gaskets and seals. Regular maintenance and inspections can prevent many issues 7.

Maintenance Tips

To prolong the life of the 5288315 Flywheel Housing, perform regular maintenance. Conduct routine inspections for wear, leaks, or misalignment. Clean the housing and surrounding components to remove debris. Ensure all fasteners are tight and the housing remains securely attached. Replace any damaged or excessively worn parts to prevent further issues 8.

Cummins Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes a wide range of power solutions, including diesel and natural gas engines, and related technologies. With a history spanning over a century, Cummins has established a strong reputation in the automotive industry for producing reliable and high-performance diesel engines and components. Their product range includes engines for on-highway and off-highway applications, filtration systems, and aftermarket parts, all designed to meet the demanding needs of various industries 9.

The Cummins part 5288315, known as the Flywheel Housing, is designed to work with several of Cummins’ engine models, including the B5.9 CM2670 B166C, ISB3.9 CM2220 B107, ISB5.9 CM2880 B127, QSB3.9 CM2880 B138, and QSB5.9 CM2880 B139 engines.

For the B5.9 CM2670 B166C and ISB3.9 CM2220 B107 engines, the Flywheel Housing ensures a secure connection between the flywheel and the engine block, facilitating smooth operation and efficient power transfer.

In the case of the ISB5.9 CM2880 B127, QSB3.9 CM2880 B138, and QSB5.9 CM2880 B139 engines, the Flywheel Housing maintains the integrity of the engine’s rotational components. This part is engineered to withstand high stresses and torques encountered during engine operation, ensuring durability and reliability.

By integrating the Flywheel Housing into these engines, Cummins guarantees robust and dependable performance, enhancing the overall efficiency and longevity of the engine systems 10.

Role of Part 5288315 Flywheel Housing in Engine Systems

The 5288315 Flywheel Housing is integral to engine systems, providing a secure enclosure for the flywheel. It aligns precisely with the crankshaft, ensuring smooth power transmission from the engine to the transmission system.

When installed, the Flywheel Housing encapsulates the flywheel, connected to the crankshaft via bolts. This arrangement allows for efficient transfer of rotational energy generated by the engine’s pistons. The housing also maintains the alignment of the clutch assembly, essential for proper engagement and disengagement during gear changes.

Additionally, the Flywheel Housing contributes to the structural integrity of the engine system by providing a robust mounting point for the clutch pressure plate. This ensures the clutch system operates under minimal stress, enhancing the durability and reliability of the entire drivetrain 11.

Conclusion

The 5288315 Flywheel Housing is a key component that facilitates the seamless interaction between the engine, flywheel, and transmission, ensuring optimal performance and longevity of the engine system. Regular maintenance and proper installation are crucial to maximizing its benefits and ensuring the reliable operation of heavy-duty trucks.

-

Gilles, T. (2020). Automotive Service: Inspection, Maintenance, Repair: 2nd Edition. Cengage Learning.

↩ -

Fijalkowski, B.T. (2011). Automotive Mechatronics Operational and Practical Issues Volume 1. Springer.

↩ -

Crolla, D. (2015). Crolla Encyclopedia. Wiley.

↩ -

Fischer, R., Kucukay, F., Jurgens, G., Najork, R., & Pollak, B. (2015). The Automotive Transmission Book Powertrain. Springer.

↩ -

Gilles, T. (2020). Automotive Service: Inspection, Maintenance, Repair: 2nd Edition. Cengage Learning.

↩ -

Fijalkowski, B.T. (2011). Automotive Mechatronics Operational and Practical Issues Volume 1. Springer.

↩ -

Crolla, D. (2015). Crolla Encyclopedia. Wiley.

↩ -

Fischer, R., Kucukay, F., Jurgens, G., Najork, R., & Pollak, B. (2015). The Automotive Transmission Book Powertrain. Springer.

↩ -

Gilles, T. (2020). Automotive Service: Inspection, Maintenance, Repair: 2nd Edition. Cengage Learning.

↩ -

Fijalkowski, B.T. (2011). Automotive Mechatronics Operational and Practical Issues Volume 1. Springer.

↩ -

Fischer, R., Kucukay, F., Jurgens, G., Najork, R., & Pollak, B. (2015). The Automotive Transmission Book Powertrain. Springer.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.