This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

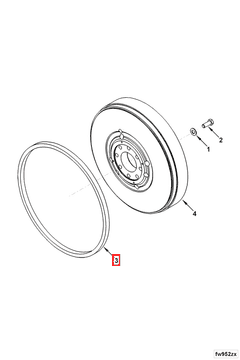

The Flywheel Ring Gear 3905427, manufactured by Cummins, is a component integral to the operation of commercial trucks. Cummins, a well-established name in the automotive industry, is recognized for its commitment to quality and innovation. This part is designed to enhance the efficiency and reliability of truck engines, playing a significant role in their overall performance.

Basic Concepts of Flywheel Ring Gear

Flywheel ring gears are fundamental components in the engine system of vehicles. They are constructed to withstand high levels of stress and wear, ensuring smooth operation of the engine. The Flywheel Ring Gear functions by engaging with the starter motor’s pinion gear during engine start-up, facilitating the transfer of rotational force to the engine. This interaction is vital for the initial cranking of the engine, which leads to its start-up 1.

Role of the Flywheel Ring Gear in Truck Operation

The Flywheel Ring Gear 3905427 is specifically designed to interact with various engine components in commercial trucks. It works in conjunction with the starter motor, transmission, and flywheel, ensuring a seamless transfer of power from the engine to the transmission system. This gear’s role is pivotal in maintaining the engine’s momentum and stability, especially during the start-up phase 2.

Key Features of the Flywheel Ring Gear 3905427

The Flywheel Ring Gear 3905427 is characterized by several key features that enhance its performance and durability. It is constructed from high-quality materials, ensuring resistance to wear and corrosion. The design of this gear includes precise engineering specifications, which allow for optimal engagement with the starter motor’s pinion gear. Additionally, its robust construction ensures longevity and reliable performance under various operating conditions 3.

Benefits of Using the Flywheel Ring Gear 3905427

Utilizing the Flywheel Ring Gear 3905427 in commercial trucks offers several advantages. It contributes to improved engine performance by ensuring efficient power transfer during start-up. The gear’s durable construction and precise engineering enhance the overall reliability and longevity of the engine system. Furthermore, its integration into the engine system can lead to smoother operation and reduced wear on associated components.

Installation and Integration

Proper installation of the Flywheel Ring Gear 3905427 is crucial for its effective functioning within the truck’s engine system. The installation process should include thorough inspection of the gear and associated components for any signs of wear or damage. It is also important to ensure that the gear is correctly aligned with the starter motor’s pinion gear to facilitate smooth engagement. Following manufacturer guidelines during installation is recommended to maintain the integrity and performance of the engine system.

Troubleshooting Common Issues

Common issues with the Flywheel Ring Gear 3905427 may include difficulty in engine start-up or unusual noises during operation. These problems can often be traced back to misalignment, wear, or damage to the gear or associated components. Troubleshooting steps may involve inspecting the gear for signs of wear, ensuring proper alignment, and checking the condition of the starter motor and flywheel. Addressing these issues promptly can help maintain the efficiency and reliability of the engine system.

Maintenance Recommendations

Routine maintenance of the Flywheel Ring Gear 3905427 is important to ensure its optimal performance and longevity. This includes regular inspection for signs of wear or damage, cleaning to remove any debris or contaminants, and ensuring proper alignment with the starter motor’s pinion gear. Adhering to recommended inspection intervals and maintenance procedures can help prevent issues and ensure the continued reliability of the engine system.

Cummins: Manufacturer Overview

Cummins is a renowned manufacturer in the automotive industry, with a history of producing high-quality and innovative components. The company’s reputation is built on its commitment to excellence, reliability, and continuous improvement in automotive technology. Cummins’ products, including the Flywheel Ring Gear 3905427, are designed with a focus on durability, performance, and compatibility with a wide range of commercial truck engines.

Cummins Flywheel Ring Gear 3905427 Compatibility

The Cummins Flywheel Ring Gear part number 3905427 is designed to fit a variety of Cummins engines, ensuring reliable and efficient performance across multiple engine models. Here’s a detailed look at the compatibility of this part with various engine types:

4B3.9 Series

- 4B3.9

6B5.9 Series

- 6B5.9

6C8.3 Series

- 6C8.3

B3.9 Series

- B3.9 G

B4.5 Series

- B4.5

- B4.5 CM2350 B129B

- B4.5 RGT

B5.9 Series

- B5.9 CM2670 B166C

- B5.9 G

- B5.9 GAS PLUS CM556

B6.7 Series

- B6.7 CM2670 B164C

- B6.7 G CMOH

- B6.7S

C Series

- C GAS PLUS CM556

D4.0 Series

- D4.0 CM2620 D103B

F2.8 Series

- F2.8 CM2620 F135B

F3.8 Series

- F3.8 CM2350 F120B

- F3.8 CM2350 F128C

- F3.8 CM2620 F137B

- F3.8 F102

F4.5 Series

- F4.5 CM2620 F139B

- F4.5 CM2620 F141C

G5.9 Series

- G5.9

- G5.9 CM558

This flywheel ring gear is engineered to meet the specific requirements of each engine model, ensuring a perfect fit and optimal performance. Whether you are working with a 4B3.9, a 6B5.9, or any other model listed, the 3905427 flywheel ring gear is a reliable choice for maintaining the integrity and efficiency of your engine.

Role of Part 3905427 Flywheel Ring Gear in Engine Systems

The Flywheel Ring Gear (Part 3905427) is a critical component in the operation of both the Flywheel and Flexplate within an engine system.

In engines equipped with a Flywheel, the Flywheel Ring Gear meshes with the starter motor’s pinion gear during engine start-up. This engagement allows the starter motor to turn the Flywheel, which in turn rotates the crankshaft, initiating the combustion process. The Flywheel also serves to smooth out the power delivery from the engine by storing rotational energy, reducing vibrations, and ensuring a consistent power transfer to the transmission.

In engines utilizing a Flexplate, the Flywheel Ring Gear performs a similar function. The Flexplate is a lighter, often cheaper alternative to the Flywheel, typically used in automatic transmission vehicles. Like the Flywheel, the Flexplate engages with the starter motor’s pinion gear to start the engine. It also helps in dampening vibrations, though it is generally less effective in this role compared to a Flywheel.

While the Fuel Filter, Fuel Filter Plumbing, and Fuel Supply Tube are not directly interacted with by the Flywheel Ring Gear, they play supporting roles in ensuring the engine operates efficiently. The Fuel Filter removes contaminants from the fuel before it reaches the engine, the Fuel Filter Plumbing ensures a secure and leak-free connection between components, and the Fuel Supply Tube delivers the filtered fuel to the engine’s fuel injection system or carburetor.

Together, these components ensure that the engine receives clean fuel and that the Flywheel or Flexplate can effectively transfer power, resulting in smooth and reliable engine operation.

Conclusion

The Flywheel Ring Gear 3905427 by Cummins is a vital component in the efficient and reliable operation of commercial truck engines. Its robust design, precise engineering, and compatibility with a wide range of Cummins engines make it an essential part for maintaining engine performance and longevity. Proper installation, regular maintenance, and prompt troubleshooting of common issues are key to ensuring the optimal functioning of this part within the engine system.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.