This is an oversize product. Additional shipping fees may apply.

This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

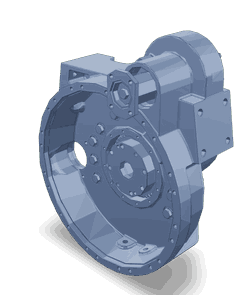

The Flywheel Top Level Assembly Housing, identified by part number 3103857, is a component manufactured by Cummins, a prominent entity in the automotive industry, particularly for its diesel engines and components. This housing is integral to the operation of heavy-duty trucks, enhancing the efficiency and reliability of the vehicle’s engine and transmission system.

Basic Concepts

Flywheels are essential in diesel engines, acting as mechanical devices that store rotational energy. They smooth out the power delivery from the engine to the transmission by compensating for the intermittent power pulses generated by the combustion process. The Flywheel Top Level Assembly Housing is a vital component in this system, providing structural support and facilitating the integration of the flywheel with other engine components.

Purpose and Function

The primary role of the Flywheel Top Level Assembly Housing is to house and support the flywheel, ensuring it operates within the designed parameters. This housing contributes to engine performance by maintaining the flywheel’s alignment and facilitating its interaction with the engine and transmission. It plays a role in the efficient transfer of power from the engine to the transmission, enhancing the overall operation of the truck.

Key Features

The Flywheel Top Level Assembly Housing is engineered with specific features to ensure optimal performance and durability. It is constructed from high-strength materials to withstand the rigors of heavy-duty applications. The design incorporates precise engineering specifications to ensure compatibility with Cummins engines and to facilitate easy installation and maintenance. Key features include robust material composition, meticulous design elements, and adherence to stringent engineering standards.

Benefits

The incorporation of the Flywheel Top Level Assembly Housing into heavy-duty trucks offers several advantages. It contributes to improved engine efficiency by ensuring the flywheel operates smoothly and effectively. The durable construction of the housing enhances the reliability and longevity of the engine and transmission system. Additionally, its design facilitates easier maintenance and troubleshooting, reducing downtime and operational costs.

Installation Process

Installing the Flywheel Top Level Assembly Housing requires careful attention to detail to ensure proper function and integration with the engine and transmission. The process involves aligning the housing with the engine components, securing it in place, and verifying its correct operation. It is important to follow manufacturer guidelines and best practices to ensure a successful installation.

Maintenance and Troubleshooting

Routine maintenance of the Flywheel Top Level Assembly Housing is crucial for ensuring optimal performance and longevity. This includes regular inspections for signs of wear or damage, cleaning, and lubrication as necessary. Troubleshooting common issues may involve checking for proper alignment, ensuring secure fastening, and addressing any signs of wear or damage promptly.

Cummins Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes a wide range of power solutions, including diesel and natural gas engines, as well as related technologies. With a rich history of innovation and a strong reputation in the automotive industry, Cummins is committed to delivering high-quality products and services that meet the demanding requirements of heavy-duty applications.

Engine Compatibility with Flywheel Top Level Assembly Housing

The Flywheel Top Level Assembly Housing, part number 3103857, manufactured by Cummins, is designed to integrate with various engine configurations. This part is compatible with the ISM CM570 and ISM CM570/870 engines, ensuring robust and reliable performance.

ISM CM570

The ISM CM570 engine is a high-performance diesel engine known for its durability and efficiency. The Flywheel Top Level Assembly Housing for this engine is engineered to provide a secure mounting point for the flywheel, ensuring smooth operation and reducing wear and tear. This housing is integral to the engine’s balance and performance, contributing to the overall reliability of the ISM CM570.

ISM CM570/870

The ISM CM570/870 engine is a variant of the ISM CM570, offering enhanced power and torque capabilities. The Flywheel Top Level Assembly Housing for this engine is designed to accommodate the increased demands placed on the engine components. This housing ensures that the flywheel operates within the optimal parameters, maintaining the engine’s efficiency and longevity. The design of this part is critical in supporting the higher performance levels of the ISM CM570/870.

By integrating the Flywheel Top Level Assembly Housing into these engines, Cummins ensures that the engines operate smoothly and efficiently, providing a reliable power source for various applications.

Understanding the Role of Part 3103857 Flywheel Top Level Assembly Housing in Engine Systems

The Flywheel Top Level Assembly Housing, part 3103857, is an integral component in the operation of various engine systems. This housing encases the flywheel, which is a rotating mechanical device that stores rotational energy and smooths out the power delivery from an engine.

Integration with the Flywheel Housing

The flywheel housing, often referred to as the bell housing, is the part of the engine block or transmission that houses the flywheel. The Flywheel Top Level Assembly Housing, part 3103857, fits snugly into this housing, ensuring a secure and precise alignment. This alignment is essential for the efficient transfer of power from the engine to the transmission.

Role in Power Transmission

As the engine’s crankshaft rotates, it drives the flywheel through the flywheel housing. The flywheel, in turn, engages with the starter motor during engine start-up, allowing the engine to crank over. Once the engine is running, the flywheel continues to rotate, storing kinetic energy that helps maintain engine momentum between power strokes.

Interaction with the Clutch System

In manual transmission vehicles, the flywheel housing also interacts with the clutch system. The Flywheel Top Level Assembly Housing ensures that the flywheel is correctly positioned relative to the pressure plate and clutch disc. This precise positioning is vital for smooth clutch engagement and disengagement, which are necessary for gear changes.

Contribution to Engine Stability

The Flywheel Top Level Assembly Housing also contributes to the overall stability of the engine. By securely holding the flywheel in place, it helps reduce vibrations and ensures consistent engine operation. This stability is particularly important in high-performance engines where precision and reliability are paramount.

Support for Ancillary Components

Additionally, the Flywheel Top Level Assembly Housing may support other ancillary components such as the flexplate in automatic transmissions or the dual-mass flywheel in some modern engines. These components rely on the housing for proper installation and function, further emphasizing the housing’s role in the engine system.

Conclusion

The Flywheel Top Level Assembly Housing, part 3103857, plays a significant role in ensuring the efficient and reliable operation of the engine and transmission system. Its precise fit within the flywheel housing and interaction with other components underscore its importance in modern engine designs.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.