This is an oversize product. Additional shipping fees may apply.

This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

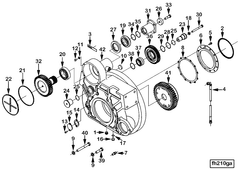

The Flywheel Top Level Assembly Housing, identified by part number 4973868, is a component manufactured by Cummins, a well-established name in the commercial truck industry. This housing is integral to the operation of heavy-duty trucks, contributing to the efficiency and reliability of the engine system.

Basic Concepts

To understand the Flywheel Top Level Assembly Housing, it is important to grasp the fundamental concepts of flywheels and their housings. A flywheel is a mechanical device that stores rotational energy and smooths out the delivery of power from a source to a load. The housing encases the flywheel, providing structural support and protection. In the context of an engine, the flywheel plays a role in maintaining rotational energy, which is essential for the smooth operation of the engine, especially during the power strokes of the combustion cycle 1.

Function and Operation

The Flywheel Top Level Assembly Housing operates within the engine system by interacting with several key components, including the crankshaft and the clutch. When the engine is running, the flywheel stores energy during the power stroke and releases it during the other strokes, helping to maintain a consistent rotational speed. This housing ensures that the flywheel is securely mounted and aligned, facilitating efficient energy transfer and reducing vibrations 2.

Purpose of the Flywheel Top Level Assembly Housing

The specific role of the Flywheel Top Level Assembly Housing (Part #4973868) in a truck is to provide a stable and secure environment for the flywheel. It aids in the storage and transmission of energy during engine cycles, ensuring that the engine operates smoothly and efficiently. By housing the flywheel, it also protects other engine components from potential damage due to flywheel malfunction.

Key Features

The Flywheel Top Level Assembly Housing is designed with several key features that enhance its performance and durability. These include a robust material composition, typically involving high-strength alloys, which provide resistance to wear and corrosion. The design elements incorporate precise engineering specifications to ensure optimal fit and function within the engine system. Additionally, the housing is crafted to withstand high temperatures and mechanical stresses, contributing to its longevity 3.

Benefits

The benefits of the Flywheel Top Level Assembly Housing include improved engine efficiency, as it helps maintain consistent rotational energy. This results in smoother engine operation and reduced wear on connected components such as the crankshaft and clutch. Furthermore, the housing contributes to the overall performance of the truck by ensuring that the flywheel functions correctly, which is vital for the engine’s reliability and durability.

Installation Process

Installing the Flywheel Top Level Assembly Housing involves several steps. First, the engine must be prepared by ensuring that all relevant components are clean and free from debris. The housing should then be aligned with the flywheel and secured in place using the appropriate fasteners. It is important to follow the manufacturer’s guidelines to ensure proper torque specifications are met. Additionally, mechanics should verify that the housing is correctly aligned with the crankshaft and clutch to prevent future issues.

Troubleshooting Common Issues

Common issues with the Flywheel Top Level Assembly Housing may include misalignment, wear, or damage to the housing itself. Symptoms of these problems can manifest as unusual engine vibrations, difficulty in shifting gears, or inconsistent engine performance. Troubleshooting steps involve inspecting the housing for signs of wear or damage, ensuring proper alignment with the flywheel and crankshaft, and verifying that all fasteners are securely tightened. If issues are detected, repairs or replacements may be necessary to restore optimal function.

Maintenance Tips

To ensure the longevity and optimal performance of the Flywheel Top Level Assembly Housing, regular maintenance is recommended. This includes periodic inspections for signs of wear or damage, cleaning the housing to remove any debris or buildup, and ensuring that all fasteners are tight. Additionally, applying the appropriate lubrication to moving parts can help reduce friction and wear. Following these maintenance tips will help maintain the efficiency and reliability of the housing and the overall engine system.

Cummins Overview

Cummins is a renowned manufacturer in the commercial truck industry, with a history of producing high-quality engine components. The company offers a wide range of products designed to meet the demanding requirements of heavy-duty applications. Cummins is known for its commitment to innovation, reliability, and performance, making it a trusted name among truck manufacturers and fleet operators.

Cummins Engine Compatibility with Flywheel Top Level Assembly Housing Part 4973868

The Flywheel Top Level Assembly Housing part 4973868, manufactured by Cummins, is designed to fit seamlessly with a range of Cummins engines. This part is integral to the engine’s operation, ensuring the flywheel assembly is securely housed and functions correctly. Below is a detailed look at the compatibility of this part with specific Cummins engine models.

ISM CM570 and QSM11 CM570

The ISM CM570 and QSM11 CM570 engines share a similar architecture, making the Flywheel Top Level Assembly Housing part 4973868 a suitable fit for both. This part ensures that the flywheel assembly is properly aligned and secured, contributing to the smooth operation and longevity of the engine.

ISM11 CM876 SN

The ISM11 CM876 SN engine, while different in specifications and design from the ISM CM570 and QSM11 CM570, also accommodates the Flywheel Top Level Assembly Housing part 4973868. This part is engineered to fit the unique requirements of the ISM11 CM876 SN, ensuring that the flywheel assembly operates efficiently and reliably within this engine model.

Grouping of Engines

The ISM CM570 and QSM11 CM570 engines can be grouped together due to their similar design and operational characteristics. This grouping highlights the interchangeability of the Flywheel Top Level Assembly Housing part 4973868 between these two engine models. On the other hand, the ISM11 CM876 SN, despite being part of the same family, has distinct features that necessitate a specific fit for the flywheel housing part.

Engine Compatibility Summary

- ISM CM570

- QSM11 CM570

- ISM11 CM876 SN

These engines, while differing in some specifications, are all compatible with the Flywheel Top Level Assembly Housing part 4973868. This compatibility ensures that the flywheel assembly is securely housed, contributing to the overall performance and durability of the engine.

Role of Part 4973868 Flywheel Top Level Assembly Housing in Engine Systems

The Part 4973868 Flywheel Top Level Assembly Housing is an integral component in the operation of engine systems, specifically designed to interface with the flywheel and housing. This assembly ensures the flywheel is securely mounted and aligned within the engine system, facilitating smooth rotational motion that is essential for the engine’s operation.

Integration with the Flywheel

The primary function of the Part 4973868 is to provide a stable and precise mounting point for the flywheel. The flywheel, a heavy rotating disc, stores rotational energy and smooths out the power delivery from the engine’s combustion cycles. The housing component of the assembly ensures that the flywheel is held in the correct position, minimizing vibrations and ensuring consistent engine performance.

Connection to the Housing

The housing, which forms part of the engine block or a separate component, is designed to encapsulate and protect the flywheel and other rotating components. The Part 4973868 Flywheel Top Level Assembly Housing interfaces directly with this housing, providing a secure and vibration-dampening connection. This integration is vital for maintaining the integrity of the engine’s rotational dynamics and protecting internal components from undue stress.

Ensuring Smooth Operation

By securely mounting the flywheel within the housing, the Part 4973868 plays a significant role in ensuring the smooth operation of the engine. It helps in maintaining the alignment of the flywheel with the crankshaft, which is essential for efficient power transmission. This alignment is crucial for the proper functioning of the clutch system, as it ensures that the flywheel engages smoothly with the clutch disc, facilitating gear changes and power delivery to the transmission system.

Vibration Dampening

One of the key benefits of the Part 4973868 is its role in vibration dampening. The assembly is designed to absorb and dissipate vibrations generated by the flywheel’s rotation. This is particularly important in high-performance engines where the flywheel operates at higher speeds and generates more vibrations. By reducing these vibrations, the assembly contributes to the overall smoothness and longevity of the engine system.

Support for Ancillary Components

Beyond its primary role with the flywheel and housing, the Part 4973868 also provides support for other ancillary components within the engine system. This includes components such as the starter motor, which relies on a stable flywheel position to engage effectively, and various sensors that monitor the flywheel’s speed and position. The assembly ensures that these components operate within their designed parameters, contributing to the engine’s overall reliability and performance.

Conclusion

The Flywheel Top Level Assembly Housing (Part #4973868) by Cummins is a critical component in the operation of heavy-duty truck engines. It ensures the flywheel is securely mounted and aligned, facilitating smooth rotational motion and efficient power transmission. The housing provides structural support, protects internal components, and contributes to the overall performance and reliability of the engine system. Regular maintenance and proper installation are essential to maximize the benefits of this part.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.