This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

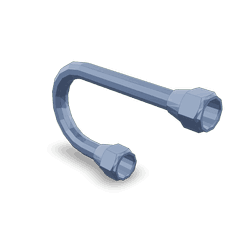

The Fuel Supply Tube 201763 by Cummins is a specialized component designed for use in commercial trucks. Its purpose is to ensure a consistent and reliable supply of fuel from the tank to the engine, which is vital for the efficient operation of the vehicle. This component is part of Cummins’ commitment to providing high-quality, durable parts that enhance the performance and reliability of commercial trucks.

Purpose and Function

The Fuel Supply Tube 201763 plays a role in the fuel system by facilitating the transfer of fuel from the tank to the engine. It is engineered to withstand the pressures and temperatures associated with fuel delivery, ensuring a steady flow of fuel that is necessary for optimal engine performance. The tube is designed to connect seamlessly with other components in the fuel system, promoting efficient fuel delivery and reducing the risk of leaks or interruptions in fuel supply 1.

Key Features

The Fuel Supply Tube 201763 is constructed from high-quality materials that offer excellent resistance to corrosion and wear. Its design includes reinforced sections to handle the pressures within the fuel system, and it features smooth internal surfaces to minimize fuel flow resistance. Additionally, the tube is equipped with precise fittings that ensure a secure connection to other fuel system components, enhancing overall system integrity 2.

Benefits

One of the primary advantages of the Fuel Supply Tube 201763 is its contribution to improved fuel efficiency. By ensuring a consistent and uninterrupted fuel supply, it helps the engine operate more efficiently. The durable construction of the tube also contributes to its reliability and longevity, reducing the need for frequent replacements and maintenance. This can lead to cost savings and increased uptime for commercial truck operators 3.

Installation and Compatibility

Proper installation of the Fuel Supply Tube 201763 is crucial for its effective operation. It should be installed according to the manufacturer’s guidelines to ensure it is securely connected and properly aligned within the fuel system. Compatibility information for specific truck models and engine types will be provided separately to ensure the correct application of this component 4.

Maintenance and Troubleshooting

Routine maintenance of the Fuel Supply Tube 201763 involves checking for signs of wear or damage, ensuring all connections are secure, and verifying that there are no leaks in the fuel system. Common issues may include fuel leaks or reduced fuel flow, which can often be traced back to loose connections or damaged sections of the tube. Troubleshooting steps may involve tightening connections, replacing damaged sections, or, in some cases, replacing the entire tube if significant wear is detected 1.

Safety Considerations

When handling and working with the Fuel Supply Tube 201763, it is important to follow safety precautions to prevent accidents. This includes working in a well-ventilated area, avoiding open flames or sparks near the fuel system, and wearing appropriate personal protective equipment. Additionally, ensuring that the fuel system is depressurized before beginning any work can help prevent fuel spills and reduce the risk of injury 2.

Cummins Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a history of innovation and quality, Cummins has established a reputation for producing reliable and high-performance automotive components. The Fuel Supply Tube 201763 is just one example of Cummins’ commitment to enhancing the efficiency and reliability of commercial vehicles through superior component design and manufacturing 3.

Integration with Other Components

The Fuel Supply Tube 201763 is integral to the fuel delivery system, connecting and facilitating the flow between various components:

-

Aeroquip Firesleeve Hose and Stratoflex Firesleeve Hose: These high-temperature, flexible hoses are often connected to the Fuel Supply Tube to facilitate the transfer of fuel from the tank to the filter. The firesleeve design provides protection against potential fuel leaks and offers resistance to high temperatures, ensuring safe and efficient fuel delivery 4.

-

Aeroquip Fuel Filter Hose and Stratoflex Fuel Filter Hose: Similar to the firesleeve hoses, these fuel filter hoses connect the Fuel Supply Tube to the fuel filter. They are designed to withstand the pressures and temperatures within the fuel system, ensuring that fuel is delivered cleanly and without contaminants 1.

-

Fuel Filter: The Fuel Supply Tube delivers fuel to the fuel filter, where impurities and contaminants are removed. This ensures that only clean fuel reaches the engine, preventing damage to sensitive components such as injectors and carburetors 2.

-

Fuel Mounting Filter: In some engine systems, a secondary fuel mounting filter may be employed. The Fuel Supply Tube plays a role in transporting fuel to this additional filter, further enhancing the purity of the fuel before it reaches the engine 3.

Overall Function

The seamless integration of the Fuel Supply Tube with these components ensures a reliable and uninterrupted fuel supply. This is vital for maintaining engine performance, reducing the risk of fuel-related issues, and enhancing the overall efficiency of the engine system. The Fuel Supply Tube’s role in connecting and facilitating the flow between these components underscores its importance in the fuel delivery network 4.

Conclusion

The Fuel Supply Tube 201763 by Cummins is a critical component in the fuel delivery system of commercial trucks. Its design and construction ensure a consistent and reliable fuel supply, contributing to improved engine performance and efficiency. Proper installation, maintenance, and adherence to safety precautions are essential for maximizing the benefits of this Cummins part.

-

Dempsey, Paul. Troubleshooting and Repairing Diesel Engines. McGraw-Hill, 2008.

↩ ↩ ↩ -

Boyce, Meherwan P. Gas Turbine Engineering Handbook 4th Edition. Butterworth-Heinemann, 2011.

↩ ↩ ↩ -

Hick, Hannes, Klaus Kupper, and Helfried Sorger. Systems Engineering for Automotive Powertrain Development. Springer, 2021.

↩ ↩ ↩ -

Bennett, Sean, and Ian Andrew Norman. Heavy Duty Truck Systems Fifth Edition. Delmar Cengage Learning, 2011.

↩ ↩ ↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.