This is an oversize product. Additional shipping fees may apply.

This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

The Cummins 2888810 Fuel Injection Pump is a critical component in the operation of heavy-duty trucks. It ensures the precise delivery of fuel to the engine cylinders, enhancing engine performance, fuel efficiency, and emissions control. This part is essential for the powertrain system in heavy-duty applications.

Basic Concepts of Fuel Injection Pumps

Fuel injection pumps convert mechanical energy into hydraulic energy to atomize fuel into the combustion chamber. They are crucial for the efficient operation of diesel engines. The difference between mechanical and electronic systems lies in the control mechanism; mechanical systems use physical components and linkages, while electronic systems employ sensors and electronic controls for more precise fuel delivery 1.

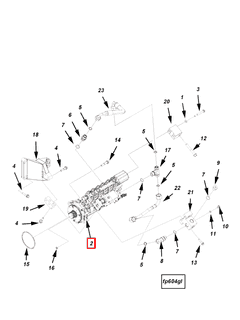

Operation of the Cummins 2888810 Fuel Injection Pump

This Cummins part operates through components such as the pump body, plungers, and cam-driven mechanisms. It pressurizes fuel and delivers it to the engine cylinders in a timed sequence, which is crucial for optimal combustion and engine performance. The pump ensures that fuel is delivered at the correct pressure and timing, contributing to the engine’s efficiency and reliability 2.

Purpose and Role in Truck Operation

In heavy-duty trucks, the Cummins 2888810 Fuel Injection Pump ensures that fuel is delivered in a manner that maximizes combustion efficiency, reduces fuel consumption, and minimizes emissions. It is engineered to meet the demanding requirements of heavy-duty applications, providing consistent and reliable performance under various operating conditions.

Key Features

The Cummins 2888810 Fuel Injection Pump features a robust design and high-quality materials. It incorporates precision-machined components, durable materials, and advanced sealing technologies. These design elements ensure that the pump can withstand heavy-duty use while maintaining optimal performance.

Benefits of Using the Cummins 2888810 Fuel Injection Pump

Using this part offers benefits such as improved engine efficiency through precise fuel delivery, better combustion, and reduced fuel consumption. It also contributes to emissions control by promoting cleaner combustion, thereby reducing the environmental impact of heavy-duty trucks. The pump’s durable construction and reliable performance result in potential cost savings for fleet operators by minimizing maintenance and repair needs 3.

Troubleshooting Common Issues

Common issues with the Cummins 2888810 Fuel Injection Pump may include leaks, inconsistent fuel delivery, and mechanical failures. Early identification of these problems can prevent more significant issues. Troubleshooting steps may involve inspecting for leaks, checking fuel delivery consistency, and assessing the condition of mechanical components.

Maintenance Tips

Regular maintenance is recommended to ensure optimal performance and longevity of the Cummins 2888810 Fuel Injection Pump. This includes conducting regular inspections to identify wear or damage, cleaning the pump and its components to prevent contamination, and replacing worn or damaged parts as needed.

Cummins Corporation Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a history of innovation and a commitment to quality, Cummins serves customers in approximately 190 countries and territories through a network of more than 600 company-owned and independent distributor facilities and more than 7,200 dealer locations. The company’s product range includes engines for on-highway, off-highway, and power generation applications, demonstrating its expertise and leadership in the diesel engine and power generation industries.

Cummins Fuel Injection Pump 2888810 Compatibility

The Cummins Fuel Injection Pump part number 2888810 is designed to be compatible with a range of Cummins engines, ensuring efficient and reliable fuel delivery. This part is engineered to fit seamlessly with the following engines:

- QSK50 CM2150 MCRS

- QSK60 CM850 MCRS

These engines share common design elements that make the 2888810 fuel injection pump a suitable match. The compatibility of this part with these engines is rooted in its robust construction and precise engineering, which aligns with Cummins’ stringent quality standards.

Role of Part 2888810 Fuel Injection Pump in Engine Systems

The part 2888810 Fuel Injection Pump is an integral component within the fuel delivery system of an engine. Its primary function is to deliver precise amounts of fuel into the combustion chamber at the exact moment required for optimal engine performance.

When the fuel injection pump receives fuel from the fuel tank via the fuel pump, it pressurizes the fuel to a high level. This pressurized fuel is then delivered to the fuel injectors. The fuel injectors atomize the fuel into a fine mist and spray it into the combustion chamber.

The timing and quantity of fuel delivery are controlled by the engine’s electronic control unit (ECU), which receives signals from various sensors such as the crankshaft position sensor, camshaft position sensor, and mass airflow sensor. These sensors provide data on engine speed, load, and air intake, allowing the ECU to make real-time adjustments to fuel delivery.

The fuel injection pump works in conjunction with other components such as the fuel filter, which ensures that any contaminants in the fuel are removed before they reach the pump. The fuel pressure regulator maintains consistent fuel pressure within the system, ensuring stable fuel delivery under varying engine conditions.

Conclusion

The Cummins 2888810 Fuel Injection Pump plays a significant role in ensuring that the engine receives the correct amount of fuel at the right time, contributing to efficient combustion, reduced emissions, and improved overall engine performance. Regular maintenance and prompt troubleshooting of common issues are essential for maintaining the pump’s efficiency and reliability.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.