This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

The Fuel Shutoff Valve Lever, identified by part number 3000740, is a component manufactured by Cummins, a well-established name in the automotive industry, particularly in the realm of heavy-duty trucks. This Cummins part plays a significant role in the operational safety and efficiency of heavy-duty trucks by managing the flow of fuel to the engine 1.

Basic Concepts

At its core, the Fuel Shutoff Valve Lever operates on the principle of controlling the fuel supply to the engine. When activated, it interrupts the fuel flow, which is a critical function for safely shutting down the engine in various scenarios. This mechanism ensures that the engine can be stopped promptly and effectively, which is vital for both operational safety and emergency situations 2.

Purpose and Function

The primary purpose of the Fuel Shutoff Valve Lever in a truck is to facilitate a controlled and immediate shutdown of the engine. This function is crucial during emergencies or when the engine needs to be stopped quickly for safety reasons. Additionally, it plays a role in routine operational procedures, allowing for a smooth transition between operational states 3.

Key Features

The 3000740 is designed with several features that enhance its performance and reliability. It is constructed from durable materials to withstand the rigors of heavy-duty truck environments. Its design ensures precise control over fuel flow, and it incorporates features that make it easy to operate under various conditions 4.

Benefits

Incorporating this Cummins part into a truck’s engine system offers several advantages. It enhances safety by providing a reliable means to shut off the engine quickly. It also contributes to better control over engine operations, which can lead to improved fuel efficiency and reduced wear on engine components.

Installation and Usage

Proper installation of the Fuel Shutoff Valve Lever is crucial for its effective operation. It should be installed according to the manufacturer’s guidelines to ensure it functions correctly within the engine system. Users should familiarize themselves with the lever’s operation to ensure they can respond appropriately in situations requiring engine shutdown.

Troubleshooting

Common issues with the Fuel Shutoff Valve Lever may include difficulty in operation or failure to shut off the engine completely. Troubleshooting steps may involve checking for obstructions, ensuring proper installation, and inspecting the lever for wear or damage. Regular checks can help identify and address issues before they lead to more significant problems.

Maintenance

Routine maintenance of the Fuel Shutoff Valve Lever is important to ensure its long-term reliability. This includes regular inspections for wear and damage, cleaning to remove any debris that may affect operation, and lubrication of moving parts to ensure smooth function. Following the manufacturer’s maintenance schedule can help prevent issues and extend the component’s lifespan.

Safety Considerations

When working with the Fuel Shutoff Valve Lever, it is important to follow safety guidelines to prevent accidents. This includes ensuring the engine is off before performing any maintenance or adjustments, wearing appropriate personal protective equipment, and being aware of the lever’s position to avoid unintentional activation.

Cummins Overview

Cummins is a leading manufacturer in the automotive industry, known for its wide range of products, including engines, filtration, and power generation equipment. With a strong reputation for quality and innovation, Cummins has been a trusted name in the industry for many years, providing reliable components for various applications, including heavy-duty trucks.

Compatibility

The Fuel Shutoff Valve Lever, part number 3000740, is a critical component in the operation of various Cummins engines, ensuring precise control over the fuel supply. This lever is designed to interface seamlessly with several engine models, providing reliable and efficient functionality.

V903 Engines

The V903 engine series, known for its robust performance and durability, is one of the key beneficiaries of the 3000740. This part is engineered to fit perfectly within the V903 engine’s architecture, ensuring smooth operation and easy maintenance. The lever’s design allows for precise control over the fuel shutoff mechanism, which is essential for both performance and safety.

Group Compatibility

The 3000740 is not limited to the V903 series alone. It is also compatible with a range of other Cummins engines, providing a versatile solution for various applications. This compatibility extends to engines that share similar design principles and operational requirements, ensuring that the lever can be used across multiple engine types without modification.

The lever’s design ensures that it can be easily integrated into the engine’s fuel system, providing a reliable means of controlling fuel flow. This compatibility is crucial for maintaining engine performance and ensuring that the fuel shutoff mechanism operates as intended.

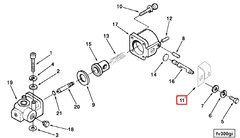

Understanding the Integration of Part 3000740 in Engine Systems

The Part 3000740 is an essential component in the orchestration of fuel management within engine systems. Its primary function is to facilitate the mechanical actuation of the fuel shutoff valve, ensuring precise control over the fuel supply to the engine.

Interaction with the Shutoff Valve

When the Fuel Shutoff Valve Lever is engaged, it directly interacts with the shutoff valve mechanism. This interaction allows for the manual or automated closure of the valve, effectively halting the fuel flow. This is particularly important during engine shutdown procedures or in emergency situations where immediate cessation of fuel is required.

Coordination with the Solenoid Valve

In systems equipped with a solenoid valve, the Fuel Shutoff Valve Lever works in tandem to enhance fuel control. The solenoid valve, which is electrically operated, can be used for fine-tuning the fuel flow. The lever, in this case, provides a mechanical backup or primary actuation method, ensuring reliability even if electrical systems fail.

Role in Valve Operation

The lever is also integral in the broader valve operation within the engine system. It ensures that the valve can be positioned accurately and held in place, whether open for fuel delivery or closed for shutdown. This mechanical precision is vital for the consistent performance and safety of the engine.

Fuel Shutoff Mechanism

In the context of the fuel shutoff mechanism, the lever acts as a pivotal point for initiating the shutoff sequence. It translates manual or automated inputs into physical movements that close the valve, thereby stopping fuel flow. This is a key safety feature, preventing fuel leakage and potential hazards.

Overall System Integration

The integration of the Fuel Shutoff Valve Lever into engine systems is designed to provide a robust and reliable method for controlling fuel flow. It works in concert with other components like the shutoff valve and solenoid valve to ensure that the engine operates efficiently and safely under all conditions.

Conclusion

The Fuel Shutoff Valve Lever (Part #3000740) by Cummins is a vital component in the management of fuel supply to heavy-duty truck engines. Its design and functionality contribute significantly to the safety, efficiency, and reliability of engine operations. Proper installation, maintenance, and understanding of its operation are crucial for maximizing the benefits this part offers.

-

Reif, Konrad Ed. Fundamentals of Automotive and Engine Technology: Standard Drives, Hybrid Drives, Brakes, Safety Systems. Springer Vieweg, 2014.

↩ -

Barton, David C and Fieldhouse, John D. Automotive Chassis Engineering Powertrain Chassis System and Vehicle Body. Elsevier, 2009.

↩ -

Duffy, Owen C and Wright, Gus. Fundamentals of Medium-Heavy Duty Commercial Vehicle Systems. Jones Bartlett Learning, 2016.

↩ -

Maclaurin, Bruce. High Speed Off-Road Vehicles. Wiley, 2018.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.