This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

The Fuel Drain Tube Assembly (Part #3009848) by Cummins is designed to facilitate the draining of fuel from the system in commercial trucks. This component is crucial for maintaining the efficiency and reliability of the vehicle’s fuel system, ensuring that fuel can be safely and efficiently removed when necessary.

Basic Concepts of Fuel Drain Tube Assembly

The operation of the Fuel Drain Tube Assembly is based on fundamental principles of fluid dynamics and system safety. This assembly is integral to the fuel system, allowing for the controlled release of fuel when draining is required. It ensures that fuel can be expelled from the system without causing spills or unsafe conditions, thereby enhancing both safety and efficiency in fuel management 1.

Purpose of the Fuel Drain Tube Assembly

The primary function of the Fuel Drain Tube Assembly is to provide a means for draining fuel from the system in a controlled manner. This is particularly important during maintenance procedures or when fuel needs to be removed for safety reasons. The assembly helps in maintaining the integrity of the fuel system by allowing for the safe removal of fuel, which can prevent contamination and ensure that the system operates efficiently 2.

Key Features

The Fuel Drain Tube Assembly is characterized by several key features that enhance its performance. Its design is engineered to fit seamlessly within the truck’s fuel system, ensuring a secure and reliable connection. The materials used in its construction are chosen for their durability and resistance to the corrosive effects of fuel, ensuring long-term reliability. Additionally, the assembly may include unique characteristics such as a built-in filter to prevent debris from entering the fuel system during draining.

Benefits

The advantages offered by the Fuel Drain Tube Assembly include improved fuel system efficiency, ease of maintenance, and enhanced reliability. By providing a dedicated pathway for fuel drainage, it simplifies maintenance procedures and reduces the risk of fuel spills. This contributes to a safer working environment and ensures that the fuel system remains clean and efficient. The reliability of the assembly also means that truck operators can trust in its performance, reducing downtime and maintenance costs 3.

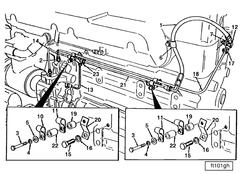

Installation Process

Installing the Fuel Drain Tube Assembly requires careful attention to detail to ensure proper function and safety. The process involves securing the assembly within the fuel system, ensuring all connections are tight and secure. Tools and equipment required may include wrenches and sealants to ensure a leak-proof installation. It is important to follow manufacturer guidelines to avoid common installation errors that could compromise the system’s integrity.

Troubleshooting Common Issues

Common problems associated with the Fuel Drain Tube Assembly may include leaks, blockages, or difficulties in draining fuel. Troubleshooting these issues involves checking for proper installation, ensuring all connections are secure, and inspecting the assembly for signs of wear or damage. Regular maintenance and inspection can help identify potential issues before they become serious problems, ensuring the continued efficiency and safety of the fuel system.

Maintenance Tips

To ensure optimal performance and longevity of the Fuel Drain Tube Assembly, regular maintenance is recommended. This includes inspecting the assembly for signs of wear or damage, cleaning it to remove any buildup, and ensuring all connections remain tight and secure. Following these maintenance tips can help prevent common issues and ensure the assembly continues to function efficiently.

About Cummins

Cummins Inc. is a global power leader that designs, manufactures, and distributes a wide range of power solutions, including engines, filtration, and emissions solutions. With a strong reputation in the commercial truck industry, Cummins is known for its commitment to quality, innovation, and customer satisfaction. The company’s extensive product range and focus on technological advancement make it a trusted partner for commercial vehicle operators worldwide.

Compatibility with Cummins Engines

N14 Mechanical

The N14 Mechanical engine, known for its robust design and durability, integrates the Fuel Drain Tube Assembly as a vital part of its fuel management system. This assembly ensures that contaminants are effectively drained, maintaining the engine’s efficiency and longevity.

NH/NT 855

Similarly, the NH/NT 855 engines benefit from the inclusion of the Fuel Drain Tube Assembly. This part is meticulously designed to fit within the intricate fuel systems of these engines, providing a reliable method for removing water and sediment. This ensures that the engine operates smoothly and efficiently, minimizing the risk of contamination-related issues.

By incorporating the Fuel Drain Tube Assembly, both the N14 Mechanical and NH/NT 855 engines maintain their operational integrity, ensuring that the fuel system remains clean and free from contaminants. This part is a testament to Cummins’ commitment to providing high-quality, reliable components for their engines.

Role of the Fuel Drain Tube Assembly in Engine Systems

The Fuel Drain Tube Assembly is an integral component in the fuel system of various engine setups. Its primary function is to facilitate the safe and efficient drainage of fuel from the system, ensuring that any excess or contaminated fuel is removed to maintain optimal engine performance.

In conjunction with fuel tubing, the Fuel Drain Tube Assembly allows for the controlled release of fuel from the system. This is particularly important during maintenance procedures, where it is necessary to drain the fuel tank or lines to perform repairs or inspections. The assembly interfaces directly with the fuel tubing, providing a secure connection point that prevents fuel leaks and ensures a consistent flow during the drainage process.

Additionally, the assembly works in tandem with the fuel filter and fuel pump. When draining the system, the Fuel Drain Tube Assembly helps to clear any debris or water that may have accumulated in the fuel lines, which can otherwise impede the fuel pump’s efficiency and clog the fuel filter. This ensures that clean fuel is delivered to the engine, promoting better combustion and overall engine health.

Conclusion

The Fuel Drain Tube Assembly (Part #3009848) by Cummins plays a significant role in maintaining the integrity and efficiency of the fuel system by enabling safe and effective fuel drainage. Its compatibility with various Cummins engines, such as the N14 Mechanical and NH/NT 855, underscores its importance in ensuring optimal engine performance. Regular maintenance and proper installation are essential to maximize the benefits of this component, contributing to the overall reliability and safety of commercial truck operations.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.