This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

The Cummins 3021951 Fuel Pump Aftercooler Body is a specialized component designed for heavy-duty trucks, particularly those equipped with Cummins engines. This part plays a crucial role in the fuel system by ensuring that the fuel delivered to the engine is at an optimal temperature, thereby contributing to the engine’s efficiency and performance 1.

Basic Concepts

To understand the function of the Cummins 3021951 Fuel Pump Aftercooler Body, it is important to grasp its role in the aftercooling process. This process involves cooling the fuel after it has been pressurized by the fuel pump. Cooling the fuel before it enters the engine enhances combustion efficiency, reduces the risk of fuel system component wear, and improves overall engine performance 2.

Purpose and Function

The primary function of the 3021951 Fuel Pump Aftercooler Body is to aid in the cooling of fuel. After the fuel has been pressurized, it passes through the aftercooler body where it is cooled before entering the engine. This cooling process helps maintain the fuel at an optimal temperature, leading to more efficient combustion and reduced engine wear. By ensuring that the fuel is at the right temperature, this component enhances the engine’s performance and efficiency 3.

Key Features

The Cummins 3021951 Fuel Pump Aftercooler Body is characterized by its robust design and the materials used in its construction. It is engineered to withstand the high pressures and temperatures associated with heavy-duty truck fuel systems. The design ensures efficient cooling of the fuel, and its construction from durable materials contributes to its longevity and reliability in demanding applications.

Benefits

Utilizing the Cummins 3021951 Fuel Pump Aftercooler Body in a truck’s fuel system can lead to several benefits. These include improved fuel efficiency due to more efficient combustion, enhanced engine performance as a result of optimal fuel temperature, and increased reliability of the fuel system components. The aftercooler body contributes to the overall durability and efficiency of the engine, making it a valuable component in heavy-duty truck applications.

Installation and Integration

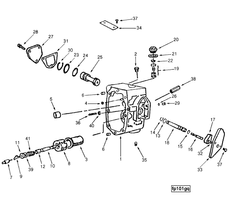

Proper installation of the Cummins 3021951 Fuel Pump Aftercooler Body is essential for ensuring its effective operation within the truck’s fuel system. Installation should follow manufacturer guidelines to ensure compatibility with the truck’s fuel system and to avoid any issues that could arise from improper installation. Considerations for installation include ensuring that all connections are secure and that the component is properly aligned within the fuel system.

Maintenance and Troubleshooting

Maintaining the Cummins 3021951 Fuel Pump Aftercooler Body is important for ensuring its continued effective operation. Regular inspections for signs of wear or damage can help identify potential issues before they lead to more significant problems. Troubleshooting common issues, such as reduced cooling efficiency or leaks, may involve checking for blockages within the cooling system or ensuring that all connections are secure. Addressing these issues promptly can help maintain the performance and reliability of the fuel system.

Cummins Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes a wide range of power solutions, including engines, filtration, emissions solutions, and related technologies. With a history of innovation and a commitment to quality, Cummins has established a reputation for producing reliable and efficient power solutions. The company’s product offerings cater to various industries, including transportation, construction, and power generation, demonstrating Cummins’ versatility and expertise in the automotive industry.

Compatibility with Cummins Engines

The Cummins part 3021951, a Fuel Pump Aftercooler Body, is designed to integrate seamlessly with several engine models, ensuring optimal performance and reliability. This component is specifically engineered to fit the K38 and K50 engines, providing a robust solution for managing fuel delivery and cooling.

For the K38 engine, the Fuel Pump Aftercooler Body is a critical part of the fuel system, ensuring that the fuel is delivered at the correct pressure and temperature. This is essential for maintaining the engine’s efficiency and longevity. The design of the part ensures that it can handle the specific demands of the K38 engine, including its unique fuel requirements and operational conditions.

Similarly, the K50 engine benefits from the precise engineering of the 3021951 part. The Fuel Pump Aftercooler Body is tailored to work with the K50’s fuel system, ensuring that the engine operates smoothly and efficiently. The part’s design allows it to effectively manage the cooling of the fuel, which is crucial for preventing overheating and maintaining the engine’s performance.

The V28 engine also utilizes the 3021951 part, highlighting its versatility and effectiveness across different engine types. The Fuel Pump Aftercooler Body is engineered to meet the specific needs of the V28 engine, ensuring that the fuel is delivered and cooled in a manner that supports the engine’s operational requirements. This part’s compatibility with the V28 engine underscores its broad applicability and reliability in various engine configurations.

Role of Part 3021951 Fuel Pump Aftercooler Body in Engine Systems

The Part 3021951 Fuel Pump Aftercooler Body is an integral component in the efficient operation of various engine systems. It interfaces seamlessly with several key components to ensure optimal performance and reliability.

Integration with Fuel Pump Systems

In systems involving the Fuel Pump, the aftercooler body plays a significant role in maintaining the temperature of the fuel. By cooling the fuel before it reaches the pump, it ensures that the fuel is at an optimal temperature, which enhances the efficiency and longevity of the pump. This is particularly important in high-performance engines where fuel temperature can significantly affect engine output and reliability.

Coordination with Fuel Pump & ACC Drive

When integrated with the Fuel Pump & ACC Drive, the aftercooler body aids in stabilizing the fuel temperature, which is essential for the consistent operation of the ACC drive. This stabilization helps in maintaining a steady fuel flow, which is vital for the precise control of engine acceleration and deceleration.

Functionality in Fuel Pump and Drive Systems

In Fuel Pump and Drive configurations, the aftercooler body ensures that the fuel delivered to the pump is cool enough to prevent vaporization. This is important for maintaining the fuel’s density and ensuring that the pump can deliver the required pressure without cavitation, which can lead to pump failure.

Role in Fuel Pump Stand Audit Kit

Within the Fuel Pump Stand Audit Kit, the aftercooler body is used to assess the thermal performance of the fuel system. It helps in identifying any potential issues related to fuel temperature, which can be indicative of larger problems within the fuel delivery system.

Application in Injector Stand Audit Kit

In the Injector Stand Audit Kit, the aftercooler body ensures that the fuel injected into the engine is at the correct temperature. This is essential for precise fuel atomization and combustion, which directly impacts engine efficiency and emissions.

Significance in Master Fuel Pump Systems

For the Master Fuel Pump, the aftercooler body is vital in preventing thermal stress on the pump. By ensuring that the fuel remains within the optimal temperature range, it helps in prolonging the life of the pump and maintaining consistent fuel delivery across varying operating conditions.

General Pump and Fuel Systems

Across general Pump and Fuel systems, the aftercooler body acts as a thermal buffer. It helps in dissipating excess heat from the fuel, which is particularly important in high-stress environments where fuel temperatures can rise rapidly.

Uncalibrated Fuel Systems

Even in Uncalibrated Fuel systems, the aftercooler body provides a baseline level of thermal management. This is beneficial in preventing unexpected failures and ensuring that the fuel system operates within safe parameters, even without precise calibration.

Conclusion

The Cummins 3021951 Fuel Pump Aftercooler Body is a critical component in the fuel systems of heavy-duty trucks, particularly those equipped with Cummins engines. Its role in cooling the fuel before it enters the engine contributes to enhanced combustion efficiency, reduced engine wear, and improved overall performance. Proper installation, maintenance, and understanding of its function are essential for maximizing the benefits of this component in demanding applications.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.