This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

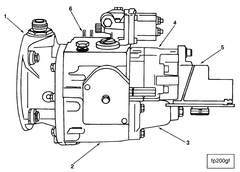

The Cummins Fuel Pump Assembly 3060178 is engineered to enhance the operational efficiency of commercial trucks by ensuring a reliable fuel supply from the tank to the engine. This component is essential for maintaining the truck’s performance and efficiency across various driving conditions.

Basic Concepts of Fuel Pump Assembly

Fuel pump assemblies, including the 3060178, are critical for transporting fuel from the tank to the engine, ensuring a consistent fuel supply necessary for combustion. Fuel pumps can be mechanical, driven by the engine’s camshaft or crankshaft, or electric, powered by the vehicle’s electrical system. Consistent fuel pressure and flow are vital for optimal engine performance, directly influencing fuel atomization and combustion efficiency 1.

Purpose of the 3060178 Fuel Pump Assembly

This Cummins part ensures that fuel is delivered to the engine under a variety of driving conditions. It maintains a steady fuel pressure, which is necessary for the engine to operate efficiently and effectively. This assembly adapts to different load conditions and driving scenarios, contributing to the overall performance and reliability of the truck.

Key Features

The 3060178 is characterized by its robust design and high-quality materials, enhancing its durability and reliability. It is engineered to integrate seamlessly with the truck’s fuel system, ensuring efficient fuel delivery. This assembly may incorporate advanced features such as improved filtration systems or enhanced pressure regulation mechanisms, contributing to its superior performance.

Benefits

The advantages of the 3060178 include improved fuel efficiency, enhanced engine performance, and increased reliability and durability. By ensuring a consistent fuel supply, this assembly optimizes the engine’s combustion process, leading to better fuel economy. Its robust construction and advanced features contribute to its longevity and dependable operation.

Installation and Integration

Proper installation of the 3060178 involves several steps to ensure it functions correctly within the truck’s fuel system. This process may require specific tools and preparations, such as ensuring the fuel tank is clean and free of contaminants. Following the manufacturer’s guidelines for installation is crucial for seamless integration and optimal performance.

Troubleshooting Common Issues

Common problems associated with fuel pump assemblies can include fuel delivery inconsistencies or pump failures. Diagnostic steps may involve checking for proper fuel pressure, inspecting electrical connections, and assessing the condition of the fuel filter. Addressing these issues promptly can help maintain the efficiency and reliability of the truck’s fuel system.

Maintenance Tips

Regular maintenance of the 3060178 is important for ensuring its longevity and optimal performance. This may include periodic inspections, cleaning the fuel system components, and replacing the assembly if signs of wear or failure are detected. Adhering to recommended maintenance schedules can help prevent unexpected failures and ensure consistent engine performance.

Cummins: A Brief Overview

Cummins Inc. is a well-established company in the commercial truck industry, known for its commitment to innovation and quality. With a diverse product range that includes engines, filtration systems, and power generation equipment, Cummins has built a reputation for delivering reliable and high-performance solutions. The company’s focus on technological advancement and customer satisfaction underscores its position as a leader in the industry 2.

Compatibility of Cummins Fuel Pump Assembly 3060178

The Cummins Fuel Pump Assembly 3060178 is designed to fit seamlessly with several engine models, ensuring optimal fuel delivery and engine performance. This part is engineered to meet the specific requirements of the N14 MECHANICAL and NH/NT 855 engines, providing a reliable solution for maintaining the efficiency and longevity of these engines.

N14 MECHANICAL Engines

The N14 MECHANICAL engine series is known for its robust design and durability, often used in heavy-duty applications. The Cummins Fuel Pump Assembly 3060178 is specifically tailored to integrate with the N14 MECHANICAL engines, ensuring that the fuel delivery system operates smoothly and efficiently. This compatibility is crucial for maintaining the engine’s performance and preventing potential issues related to fuel supply.

NH/NT 855 Engines

Similarly, the NH/NT 855 engines benefit from the precise engineering of the Cummins Fuel Pump Assembly 3060178. These engines are widely used in various industrial and commercial applications, and the fuel pump assembly is designed to fit these engines perfectly. This ensures that the fuel system functions correctly, contributing to the overall reliability and efficiency of the NH/NT 855 engines.

By ensuring that the Cummins Fuel Pump Assembly 3060178 is compatible with both the N14 MECHANICAL and NH/NT 855 engines, Cummins provides a reliable and efficient solution for maintaining the performance of these engines. This compatibility is essential for operators who rely on these engines for their daily operations, ensuring that they can maintain productivity without the worry of fuel system failures.

Role of Part 3060178 Fuel Pump Assembly in Engine Systems

The 3060178 Fuel Pump Assembly is integral to the efficient operation of engine systems, ensuring a consistent supply of fuel to the combustion chambers. This assembly interfaces with several key components to maintain optimal engine performance.

Integration with Fuel System Components

-

Fuel Pump: The 3060178 assembly houses the fuel pump, which is responsible for drawing fuel from the tank and pressurizing it to the required levels for injection into the engine. The pump’s operation is synchronized with the engine’s demand, ensuring that fuel delivery is both timely and precise.

-

Fuel Lines and Tubing: The assembly is connected to the fuel lines and tubing, which transport fuel from the tank to the engine. These connections must be secure to prevent leaks and ensure that fuel flow is uninterrupted. The assembly includes fittings that mate with the fuel lines, facilitating a smooth transition from the pump to the delivery system.

-

Fuel Filter: Often integrated within the assembly, the fuel filter screens out impurities from the fuel before it reaches the engine. This protects the injectors and other sensitive components from damage caused by contaminants.

-

Pressure Regulator: The assembly may also include a pressure regulator, which maintains a consistent fuel pressure within the system. This is essential for the injectors to operate correctly, as variations in pressure can lead to inefficient combustion and reduced engine performance.

-

Electrical Connections: The fuel pump within the assembly is powered by electrical connections from the vehicle’s battery. These connections must be reliable to ensure that the pump operates whenever the engine is running.

-

Sensors and Monitoring: Some advanced assemblies include sensors that monitor fuel pressure and temperature. These sensors provide feedback to the engine control unit (ECU), allowing for adjustments to be made in real-time to optimize fuel delivery and engine performance.

By understanding how the 3060178 Fuel Pump Assembly interacts with these components, engineers and mechanics can better diagnose issues, perform maintenance, and ensure that the fuel system operates at peak efficiency.

Conclusion

The Cummins Fuel Pump Assembly 3060178 plays a crucial role in the efficient operation of commercial trucks by ensuring a reliable and consistent fuel supply to the engine. Its robust design, compatibility with key engine models, and integration with various fuel system components make it a vital part of maintaining engine performance and reliability. Regular maintenance and proper installation are essential for maximizing the benefits of this assembly.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.