This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

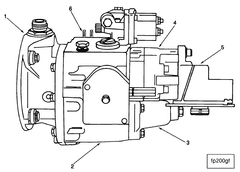

The Cummins 3060180 Fuel Pump is a component designed for use in commercial trucks. It serves to deliver fuel from the tank to the engine, ensuring that the engine receives a consistent supply of fuel under varying operational conditions. This part is significant in maintaining the efficiency and performance of the truck’s engine 1.

Basic Concepts of Fuel Pumps

A fuel pump is a device that moves fuel from the fuel tank to the engine. It operates by creating pressure that pushes the fuel through the lines to the engine. There are several types of fuel pumps, including mechanical, electric, and high-pressure pumps, each suited to different engine requirements and designs 2.

Role of the 3060180 Fuel Pump in Truck Operation

The Cummins 3060180 Fuel Pump plays a specific role in the fuel delivery system of a truck. It ensures that fuel is delivered at a consistent pressure and flow rate, which is vital for the engine’s combustion process. This pump is designed to handle the demands of heavy-duty applications, providing reliable fuel delivery under a range of operating conditions 3.

Key Features of the 3060180 Fuel Pump

The primary features of the Cummins 3060180 Fuel Pump include its robust design, which is built to withstand the rigors of commercial truck use. It is constructed from high-quality materials to ensure durability and longevity. Additionally, the pump incorporates advanced technological aspects that enhance its performance and efficiency.

Benefits of Using the 3060180 Fuel Pump

The Cummins 3060180 Fuel Pump offers several advantages. It contributes to improved fuel efficiency by ensuring that the engine receives a precise amount of fuel. Its reliable operation and durable construction make it suitable for heavy-duty applications, providing consistent performance over time.

Installation and Integration

Proper installation of the Cummins 3060180 Fuel Pump within a truck’s fuel system is important for its effective operation. This process involves ensuring that the pump is correctly positioned and securely attached to the fuel lines. It is also important to verify that the electrical connections are properly made if the pump is electric.

Maintenance and Troubleshooting

Regular maintenance practices are recommended to ensure the longevity and optimal performance of the Cummins 3060180 Fuel Pump. This includes checking for leaks, ensuring electrical connections are secure, and monitoring the pump’s operation for any signs of wear or failure. Troubleshooting tips may involve checking for proper fuel pressure and flow, and addressing any issues promptly to prevent further damage.

Common Issues and Solutions

Common problems associated with fuel pumps, including the Cummins 3060180 model, can include fuel leaks, inconsistent fuel pressure, and electrical issues. Suggested solutions or maintenance actions to address these issues may involve replacing worn seals, adjusting fuel pressure settings, or repairing electrical connections.

Cummins Corporation Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a history of innovation and quality, Cummins serves commercial vehicle, industrial, and power generation markets. The company is known for its commitment to reliability and performance in the commercial vehicle industry.

Cummins Fuel Pump 3060180 Compatibility

The Cummins Fuel Pump part number 3060180 is designed to integrate seamlessly with a variety of engine models, ensuring optimal fuel delivery and engine performance. This fuel pump is engineered to meet the specific needs of different engine configurations, providing reliable operation across multiple applications.

N14 Mechanical Engines

For the N14 Mechanical engines, the Cummins Fuel Pump 3060180 is a critical component that ensures the engine receives the necessary fuel pressure and flow. This part is engineered to fit precisely within the engine’s fuel system, facilitating smooth and efficient operation. The N14 Mechanical engines benefit from this fuel pump’s robust design, which supports high-performance demands and durability.

NH/NT 855 Engines

Similarly, the Cummins Fuel Pump 3060180 is also compatible with the NH/NT 855 engines. This part is tailored to fit within the intricate fuel systems of these engines, ensuring that they receive the appropriate fuel supply for optimal performance. The design of this fuel pump aligns with the specific requirements of the NH/NT 855 engines, providing a reliable and efficient solution for maintaining fuel delivery.

Grouping of Engines

Both the N14 Mechanical and NH/NT 855 engines share common design principles in their fuel systems, which allows the Cummins Fuel Pump 3060180 to be a versatile component across these engine types. This compatibility ensures that technicians and operators can confidently use this part across different engine models, simplifying maintenance and repair processes. The design of the fuel pump is such that it can be easily integrated into the existing fuel systems of these engines, ensuring seamless operation and performance.

Role of Part 3060180 Fuel Pump in Engine Systems

The part 3060180 Fuel Pump is integral to the functionality of engine systems by ensuring a consistent and adequate supply of fuel to the combustion chambers. This component operates in conjunction with several other parts to maintain optimal engine performance.

Integration with Fuel System Components

-

Fuel Tank: The fuel pump draws fuel from the tank, where it is stored. The pump’s efficiency in this process ensures that the fuel delivery system operates smoothly without interruptions.

-

Fuel Filter: Before the fuel reaches the engine, it passes through the fuel filter. The fuel pump provides the necessary pressure to push the fuel through this filter, removing any impurities that could damage the engine components.

-

Fuel Lines: The pump sends pressurized fuel through the fuel lines to the engine. The consistent pressure maintained by the fuel pump is essential for the proper functioning of fuel injectors or carburetors.

-

Fuel Injectors: In modern engines, the fuel pump supplies fuel to the injectors, which spray atomized fuel into the combustion chambers. The precise pressure delivered by the pump ensures that the injectors operate correctly, promoting efficient combustion.

-

Carburetor: In older engine systems, the fuel pump provides the necessary pressure to the carburetor, where fuel is mixed with air before entering the combustion chamber. This ensures a proper air-fuel mixture for combustion.

-

Fuel Pressure Regulator: The fuel pump works in tandem with the fuel pressure regulator to maintain a consistent fuel pressure within the system. This regulator helps in fine-tuning the fuel delivery to meet the engine’s demands under various operating conditions.

-

Engine Control Unit (ECU): The ECU monitors the fuel system and adjusts the fuel pump’s operation based on sensor inputs. This ensures that the engine receives the appropriate amount of fuel for optimal performance and efficiency.

Operational Synergy

The part 3060180 Fuel Pump’s role extends beyond mere fuel delivery. It ensures that the entire fuel system operates in harmony. By providing a steady fuel supply under varying engine loads and speeds, the fuel pump contributes to smooth engine operation, reduced emissions, and improved fuel economy.

Conclusion

In summary, the Cummins 3060180 Fuel Pump is a critical component in the fuel delivery system of commercial trucks. Its robust design, compatibility with various engine models, and integration with other fuel system components ensure efficient and reliable engine performance. Regular maintenance and prompt troubleshooting are essential to maximize the longevity and effectiveness of this part.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.