This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

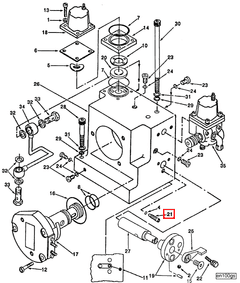

The Fuel Pump Adjusting Screw (Part #3063889) by Cummins is a component designed to fine-tune the operation of fuel pumps in heavy-duty trucks. This screw plays a role in ensuring the fuel system operates efficiently, contributing to the overall performance and reliability of the vehicle.

Purpose and Function

The Fuel Pump Adjusting Screw is integral to the fuel system of heavy-duty trucks. It allows for the precise regulation of fuel delivery to the engine. By adjusting the screw, operators can optimize fuel flow, which directly influences engine performance. This adjustment capability ensures that the engine receives the correct amount of fuel under varying operating conditions, thereby enhancing efficiency and power output 1.

Key Features

The Fuel Pump Adjusting Screw is characterized by its robust design and the use of high-quality materials. It is crafted to withstand the demanding conditions typical of heavy-duty truck operations. The screw features a precise threading mechanism that allows for fine adjustments, ensuring accurate fuel delivery. Additionally, its construction includes corrosion-resistant materials, which enhance its durability and longevity in harsh environments 2.

Benefits

Incorporating the Fuel Pump Adjusting Screw into the fuel system offers several advantages. It contributes to improved fuel efficiency by ensuring that the engine receives the optimal amount of fuel. This precise control over fuel delivery also enhances engine performance, allowing for smoother operation and increased power. Furthermore, the screw’s design and materials ensure reliability, even in demanding operating conditions, which is crucial for the sustained performance of heavy-duty trucks 3.

Installation and Adjustment

Proper installation and adjustment of the Fuel Pump Adjusting Screw are vital for optimal performance. The installation process involves securing the screw into the fuel pump assembly according to the manufacturer’s specifications. Adjustment should be performed with careful attention to the engine’s requirements and operating conditions. It is important to follow the recommended procedures to ensure that the fuel delivery is correctly calibrated for the best engine performance 4.

Troubleshooting and Maintenance

Common issues with the Fuel Pump Adjusting Screw may include improper fuel delivery or engine performance irregularities. Troubleshooting steps involve checking the screw’s position and ensuring it is correctly installed. Regular maintenance, such as inspecting for wear or damage and ensuring the screw is free from debris, is recommended to maintain its functionality. Keeping the screw and surrounding components clean and well-lubricated can also contribute to its longevity and consistent performance.

Safety Considerations

When working with the Fuel Pump Adjusting Screw, it is important to observe safety precautions. This includes ensuring the engine is off and the fuel system is depressurized before beginning any work. Use appropriate personal protective equipment, such as gloves and safety glasses, to protect against potential hazards. Follow all manufacturer guidelines for handling, installation, and maintenance to ensure safe and effective operation.

Cummins Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes a wide range of power solutions, including engines, filtration, and emissions technologies. With a history of innovation and a commitment to quality, Cummins has established a strong reputation in the automotive industry. The company’s product offerings are designed to meet the demanding requirements of heavy-duty applications, ensuring reliability and performance in various operating conditions. Cummins’ dedication to quality and innovation is evident in its components, including the Fuel Pump Adjusting Screw.

Compatibility of Fuel Pump Adjusting Screw (Part 3063889)

The Cummins Fuel Pump Adjusting Screw, identified by part number 3063889, is a component in the fuel delivery system of certain Cummins engines. This part is designed to fine-tune the fuel pump’s operation, ensuring optimal fuel delivery and engine performance.

L10 Mechanical Engine

In the L10 Mechanical engine, the Fuel Pump Adjusting Screw plays a role in maintaining the precise fuel pressure required for efficient combustion. This engine, known for its robust design and reliability, benefits from the careful calibration provided by the adjusting screw. Proper adjustment ensures that the engine operates within its designed parameters, enhancing both performance and longevity.

N14 Mechanical Engine

Similarly, in the N14 Mechanical engine, the Fuel Pump Adjusting Screw is integral to the engine’s fuel management system. The N14 engine, renowned for its power and durability, relies on this component to maintain the correct fuel delivery rate. The adjusting screw allows for the fine-tuning of the fuel pump, which is crucial for achieving the desired balance between performance and fuel efficiency.

Grouping of Engines

Both the L10 and N14 Mechanical engines share a common need for precise fuel management, making the Fuel Pump Adjusting Screw a critical part for both. The design and function of the screw are tailored to meet the specific requirements of these engines, ensuring that they can operate efficiently and reliably under various conditions.

By understanding the importance of the Fuel Pump Adjusting Screw in these engines, mechanics and technicians can ensure that their maintenance and repair procedures are thorough and effective, ultimately contributing to the longevity and performance of the engines.

Role of Part 3063889 Fuel Pump Adjusting Screw in Engine Systems

The Fuel Pump Adjusting Screw is integral to the fine-tuning and optimal performance of various engine systems. This component is specifically designed to interact with the fuel pump, ensuring that the fuel delivery system operates within precise parameters.

When integrated with the fuel pump, the adjusting screw allows for meticulous calibration of the fuel pressure. This is essential for maintaining the correct fuel flow rate, which directly influences engine performance and fuel efficiency. By making slight adjustments to the screw, technicians can ensure that the fuel pump delivers the optimal amount of fuel under varying engine loads and conditions.

In conjunction with the pace module, the Fuel Pump Adjusting Screw plays a role in synchronizing the fuel delivery with the engine’s operational demands. The pace module regulates the timing and amount of fuel injected into the combustion chamber. The adjusting screw ensures that the fuel pump’s output aligns perfectly with these regulations, thereby enhancing overall engine responsiveness and stability.

The interaction between the adjusting screw and the fuel injection system is also noteworthy. Proper fuel pressure, as adjusted by the screw, ensures that the fuel injectors operate efficiently. This results in a more consistent and precise fuel spray, which is vital for combustion efficiency and reducing emissions.

Overall, the Fuel Pump Adjusting Screw is a key component in ensuring that the fuel delivery system within engine systems operates harmoniously, leading to improved performance, efficiency, and reliability.

Conclusion

The Fuel Pump Adjusting Screw (Part #3063889) by Cummins is a critical component for the efficient operation of fuel systems in heavy-duty trucks. Its precise adjustment capabilities ensure optimal fuel delivery, enhancing engine performance and reliability. The robust design and high-quality materials of this part contribute to its durability and effectiveness in demanding conditions. Proper installation, adjustment, and maintenance are essential for maximizing the benefits of this component, ensuring the sustained performance of heavy-duty engines.

-

Dixon, J. (2014). Modern Diesel Technology: Heating, Ventilation, Air Conditioning, Refrigeration, 2nd Edition. Cengage Learning.

↩ -

Garrett, T.K., Newton, K., & Steeds, W. (2001). The Motor Vehicle. Reed Educational and Professional Publishing Ltd.

↩ -

Hilgers, M. (2023). Electrical Systems and Mechatronics, Second Edition. Springer Vieweg.

↩ -

Gillespie, T.D. (2021). Fundamentals of Vehicle Dynamics. SAE International.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.