This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

The Cummins 3914871 Fuel Injection Pump is a component designed for use in heavy-duty trucks, manufactured by Cummins Inc. This pump is integral to the operation of diesel engines, ensuring efficient fuel delivery to the engine cylinders. Cummins Inc., a well-established name in the automotive industry, is known for its commitment to innovation and quality in manufacturing fuel injection systems and other automotive components 1.

Basic Concepts of Fuel Injection Pumps

A fuel injection pump is a device that delivers fuel to the engine’s combustion chambers at precise moments and in specific quantities. In diesel engines, this pump plays a role in the fuel delivery system by atomizing the fuel and injecting it into the cylinders under high pressure. This process differs from other fuel delivery systems, such as carburetors, by providing more controlled and efficient fuel delivery, which is crucial for the performance and efficiency of diesel engines 2.

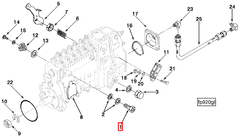

Operation of the Cummins 3914871 Fuel Injection Pump

The Cummins 3914871 operates through a series of mechanical and hydraulic processes. It consists of several components, including a cam-driven plunger, a high-pressure fuel line, and injectors. The pump’s operation begins when the engine’s camshaft rotates, driving the plunger within the pump. This action creates high-pressure fuel, which is then delivered to the injectors. The injectors, in turn, spray the fuel into the engine cylinders at the optimal moment for combustion.

Role in Truck Operation

The Cummins 3914871 plays a significant role in the overall operation of a heavy-duty truck. By ensuring precise fuel delivery, it contributes to the engine’s performance and efficiency. The pump’s ability to deliver fuel at the right pressure and timing enhances the engine’s power output and fuel economy, making it a vital component in the truck’s powertrain system 3.

Key Features

The Cummins 3914871 is characterized by its robust design and the use of high-quality materials. It incorporates advanced technological aspects, such as precise manufacturing tolerances and durable components, to ensure reliable operation under the demanding conditions typical of heavy-duty truck applications.

Benefits

The use of the Cummins 3914871 offers several benefits, including improved fuel efficiency, enhanced engine performance, and increased reliability. Its precise fuel delivery system allows for more efficient combustion, leading to better fuel economy and reduced emissions. Additionally, the pump’s durable construction and advanced technology contribute to its reliability and longevity.

Troubleshooting and Maintenance

Common issues with the Cummins 3914871 may include fuel delivery problems, such as leaks or inconsistent fuel pressure. Troubleshooting steps may involve checking for leaks, ensuring proper fuel line connections, and inspecting the pump’s components for wear or damage. Regular maintenance practices, such as cleaning the fuel system and replacing worn parts, are crucial for ensuring the pump’s longevity and optimal performance.

Integration with Engine Management Systems

The Cummins 3914871 is designed to integrate with modern engine management systems. This integration allows for optimized fuel delivery and engine performance by enabling the engine control unit (ECU) to adjust fuel injection timing and quantity based on real-time engine conditions. This synergy between the pump and the engine management system enhances the engine’s efficiency and responsiveness.

Environmental Impact

The use of the Cummins 3914871 contributes to reduced environmental impact by improving fuel efficiency and reducing emissions. Its precise fuel delivery system ensures more complete combustion, leading to lower emissions of pollutants. Additionally, the pump’s efficiency in fuel delivery helps in reducing overall fuel consumption, contributing to a smaller carbon footprint.

Cummins Inc.

Cummins Inc. is a leading manufacturer in the automotive industry, with a reputation for innovation and quality. The company has a long history of developing advanced fuel injection systems and other automotive components. Cummins’ commitment to research and development ensures that its products, including the 3914871, meet the highest standards of performance, reliability, and environmental responsibility.

Role of Part 3914871 Fuel Injection Pump in Engine Systems

The 3914871 Fuel Injection Pump is a pivotal component in the orchestration of fuel delivery within engine systems. It works in concert with several other components to ensure efficient and precise fuel distribution, which is essential for optimal engine performance.

Integration with the Base Fuel Pump

The Base Fuel Pump serves as the initial stage in the fuel delivery process, drawing fuel from the tank and pressurizing it to a level suitable for further processing. The 3914871 takes over from this point, receiving the pressurized fuel and refining its delivery. It precisely meters the fuel and injects it into the combustion chamber at the exact moment required for efficient combustion. This synergy between the base fuel pump and the fuel injection pump ensures a consistent and reliable fuel supply, which is fundamental for stable engine operation.

Interaction with Fuel Injectors

Once the fuel is metered by the 3914871, it is delivered to the Fuel Injectors. These injectors are responsible for spraying the fuel into the combustion chamber in a fine mist, maximizing the surface area for combustion. The injection pump’s role here is to provide the injectors with fuel at the correct pressure and timing, ensuring that the fuel is atomized effectively and combusts efficiently.

Coordination with Engine Control Unit (ECU)

The Engine Control Unit (ECU) plays a significant role in the operation of the 3914871. The ECU monitors various engine parameters such as engine speed, load, and temperature. Based on this data, it sends signals to the fuel injection pump to adjust the fuel delivery accordingly. This real-time feedback loop allows for precise control over fuel injection, optimizing performance, fuel economy, and emissions.

Relationship with Fuel Rail and Pressure Regulator

The Fuel Rail distributes the pressurized fuel from the injection pump to each individual injector. The Pressure Regulator, often integrated into the fuel rail or the injection pump itself, maintains a consistent fuel pressure within the system. The 3914871 must work in harmony with these components to ensure that the fuel pressure remains within the desired range, facilitating smooth and reliable fuel delivery to the injectors.

Contribution to Overall Engine Efficiency

By ensuring that the fuel is delivered at the precise moment and in the exact quantity required, the 3914871 contributes significantly to the overall efficiency of the engine. It helps in achieving a better air-fuel mixture, which leads to more complete combustion, reduced emissions, and improved fuel economy. Additionally, it plays a part in enhancing the engine’s responsiveness and power output by providing consistent and reliable fuel delivery under varying operating conditions.

Conclusion

The Cummins 3914871 Fuel Injection Pump is a critical component in the efficient operation of diesel engines in heavy-duty trucks. Its precise fuel delivery system, robust design, and integration with modern engine management systems contribute to enhanced engine performance, fuel efficiency, and reduced environmental impact. Regular maintenance and troubleshooting are essential for ensuring the longevity and optimal performance of this Cummins part.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.