This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

The Cummins 3915959 Fuel Injection Pump is a critical component in the operation of commercial trucks. It is designed to deliver precise amounts of fuel to the engine, ensuring efficient combustion and optimal performance. This part is integral to the functionality of diesel engines, particularly in heavy-duty applications where reliability and efficiency are paramount.

Basic Concepts of Fuel Injection Pumps

A fuel injection pump is a device that pressurizes and delivers fuel to the engine’s combustion chambers. In diesel engines, the pump plays a role in the fuel delivery system by atomizing fuel into a fine mist, which then mixes with air for combustion 3. There are two primary types of fuel injection systems: mechanical and electronic. Mechanical systems rely on physical components and cam-driven mechanisms to control fuel delivery, while electronic systems use sensors and computer controls to manage fuel injection more precisely 1.

Purpose and Function of the Cummins 3915959 Fuel Injection Pump

This Cummins part is engineered to deliver fuel to the engine under high pressure. It ensures that the fuel is atomized correctly, which is crucial for efficient combustion. By maintaining consistent fuel delivery, the pump contributes to the engine’s power output and overall performance. It operates in synchronization with the engine’s rotation, injecting fuel at the precise moment required for combustion 2.

Key Features of the Cummins 3915959 Fuel Injection Pump

The Cummins 3915959 Fuel Injection Pump boasts several key features that enhance its performance. Its design includes high-precision components that ensure accurate fuel metering. The pump incorporates durable materials to withstand the rigors of heavy-duty use. Additionally, it features advanced sealing technologies to prevent fuel leaks and maintain system integrity.

Benefits of Using the Cummins 3915959 Fuel Injection Pump

Utilizing this Cummins part offers several advantages. It contributes to improved fuel efficiency by ensuring that fuel is delivered precisely when needed. This results in better engine performance and reduced fuel consumption. The pump’s reliable operation also enhances the overall reliability of the engine, leading to fewer downtimes and lower maintenance costs 4.

Troubleshooting Common Issues

Common issues with the Cummins 3915959 Fuel Injection Pump may include poor engine performance, irregular idling, and fuel delivery problems. To troubleshoot these issues, it is important to perform a systematic diagnosis. This may involve checking for fuel leaks, inspecting the pump’s components for wear, and ensuring that the pump is properly calibrated. Regular maintenance and timely replacement of worn-out parts can prevent many of these issues.

Maintenance and Care

To ensure the longevity and optimal performance of the Cummins 3915959 Fuel Injection Pump, regular maintenance is necessary. This includes routine checks for leaks, cleaning the pump and its components, and replacing any worn-out parts. Adhering to the manufacturer’s recommended maintenance schedule will help maintain the pump’s efficiency and reliability.

Integration with Engine Management Systems

The Cummins 3915959 Fuel Injection Pump is designed to integrate seamlessly with modern engine management systems. Proper calibration and compatibility with these systems are important for ensuring that the pump operates efficiently. This integration allows for precise control over fuel delivery, enhancing the engine’s performance and emissions compliance.

Environmental and Efficiency Considerations

The Cummins 3915959 Fuel Injection Pump plays a role in reducing emissions and improving fuel efficiency in commercial trucks. By ensuring precise fuel delivery, it helps the engine operate more cleanly and efficiently. This contributes to meeting environmental regulations and reducing the overall carbon footprint of heavy-duty trucks 3.

Cummins: A Brief Overview

Cummins Inc. is a renowned manufacturer in the commercial truck industry, known for its commitment to innovation and quality. With a rich history of producing reliable diesel engines and components, Cummins has established a strong reputation for excellence. The company continually invests in research and development to enhance the performance and efficiency of its products, ensuring they meet the demanding requirements of modern commercial applications.

Compatibility of Cummins Fuel Injection Pump 3915959

The Cummins Fuel Injection Pump part number 3915959 is a critical component in the fuel delivery system of various engines. This part is designed to ensure precise fuel metering and injection timing, which are essential for optimal engine performance and efficiency. Below is a detailed overview of the engines with which this fuel injection pump is compatible.

6C8.3 Engine Series

The Cummins 6C8.3 engine is a robust and reliable power unit often utilized in heavy-duty applications. The 6C8.3 engine series benefits significantly from the precise fuel delivery provided by the 3915959 fuel injection pump. This compatibility ensures that the engine operates with the necessary fuel efficiency and power output, making it suitable for demanding tasks.

Compatibility Grouping

The Cummins Fuel Injection Pump 3915959 is not limited to a single engine model but is designed to fit within a specific group of engines that share similar design and operational parameters. This grouping ensures that the pump can effectively manage the fuel requirements of these engines, providing consistent performance across the board.

Engine Grouping

The 3915959 fuel injection pump is compatible with the following engines:

- 6C8.3 Series: This series includes various models that benefit from the precise fuel injection capabilities of the 3915959 pump. The compatibility ensures that these engines maintain optimal performance levels.

Application Considerations

When installing the Cummins Fuel Injection Pump 3915959, it is crucial to consider the specific requirements of the engine it will be paired with. Proper installation and calibration are essential to ensure that the pump delivers the correct fuel pressure and timing, which directly impacts engine performance and longevity. Technicians and operators should refer to the manufacturer’s guidelines for detailed installation and maintenance procedures to maximize the pump’s effectiveness 4.

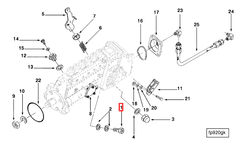

Role of Part 3915959 Fuel Injection Pump in Engine Systems

The part 3915959 Fuel Injection Pump is integral to the efficient operation of modern engine systems. It works in concert with several key components to ensure optimal fuel delivery and engine performance.

Interaction with the Base Fuel Pump

The base fuel pump is responsible for drawing fuel from the tank and delivering it to the fuel injection pump. The part 3915959 Fuel Injection Pump then takes over, pressurizing the fuel to the levels required for injection into the engine cylinders. This pressurized fuel is essential for achieving the fine mist needed for efficient combustion.

Fuel Rail and Injectors

Once pressurized by the fuel injection pump, the fuel travels through the fuel rail, a distribution pipeline that supplies fuel to each injector. The part 3915959 ensures consistent pressure across the rail, allowing each injector to deliver an accurate amount of fuel at the precise moment. This timing is vital for maintaining engine efficiency and reducing emissions.

Engine Control Unit (ECU)

The Engine Control Unit (ECU) monitors various engine parameters and adjusts the operation of the part 3915959 Fuel Injection Pump accordingly. Sensors provide real-time data on engine load, speed, and other factors, allowing the ECU to fine-tune fuel delivery for optimal performance under varying conditions.

High-Pressure Fuel System

In many advanced engine systems, the part 3915959 is part of a high-pressure fuel system that includes components like the common rail. This system allows for even more precise control over fuel injection, enhancing both performance and fuel economy.

Return System

Excess fuel not injected into the cylinders is returned to the tank via the return system. The part 3915959 Fuel Injection Pump manages this return flow, ensuring that the system operates within safe pressure limits and maintains efficiency.

Integration with Turbochargers

In turbocharged engines, the part 3915959 Fuel Injection Pump must work in harmony with the turbocharger to deliver the right amount of fuel to match the increased air intake. This ensures that the engine receives the optimal air-fuel mixture, maximizing power output while minimizing the risk of knocking or other performance issues.

By understanding how the part 3915959 Fuel Injection Pump interacts with these components, engineers and mechanics can better diagnose issues, perform maintenance, and optimize engine performance.

Conclusion

The Cummins 3915959 Fuel Injection Pump is a vital component in the efficient operation of commercial truck engines. Its precise fuel delivery capabilities ensure optimal engine performance, improved fuel efficiency, and reduced emissions. Regular maintenance and proper integration with engine management systems are essential for maximizing the benefits of this Cummins part. Understanding its role within the engine system allows for better troubleshooting, maintenance, and overall optimization of engine performance.

-

Bonnick, Allan, and Derek Newbold. A Practical Approach to Motor Vehicle Engineering and Maintenance, Third Edition. Elsevier Ltd, 2011.

↩ -

Caines, Arthur J, Roger F Haycock, and John E Hillier. Automotive Lubricants Reference Book. SAE International, 2004.

↩ -

Hilgers, Michael. Fuel Consumption and Consumption Optimization, Second Edition. Springer Nature, 2023.

↩ ↩ -

Cummins Inc. Operation and Maintenance Manual. Bulletin Number 5613394, QSK38 CM2350 K138M.

↩ ↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.