This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

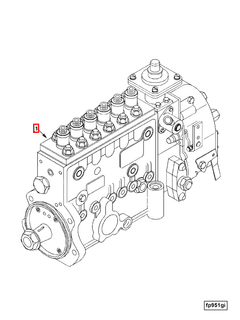

The Cummins 3929602 Fuel Injection Pump is a significant component in the automotive industry, particularly within the realm of diesel engines. Its primary function is to deliver fuel to the engine cylinders in precise amounts and at the correct timing, which is vital for the efficient operation of diesel engines 2.

Basic Concepts of Fuel Injection Pumps

A fuel injection pump is a device that pressurizes fuel and delivers it to the engine’s combustion chambers. It operates by drawing fuel from the tank, pressurizing it, and injecting it into the cylinders at specific intervals. In diesel engines, the fuel injection pump plays a role in the fuel delivery system. There are two main types of fuel injection pumps: mechanical and electronic. Mechanical pumps rely on engine-driven components to control fuel delivery, whereas electronic pumps use sensors and electronic controls to optimize fuel injection based on engine conditions and performance requirements 1.

Purpose of the Cummins 3929602 Fuel Injection Pump

The Cummins 3929602 Fuel Injection Pump is designed to ensure that the diesel engine receives the correct amount of fuel at the precise moment. This component plays a role in the engine’s operation by delivering fuel to the cylinders, which contributes to the engine’s power output, efficiency, and overall performance 2.

Key Features

The Cummins 3929602 Fuel Injection Pump is characterized by its robust design and the use of high-quality materials, which contribute to its durability and performance. It incorporates advanced technological features such as precise fuel metering and electronic controls that enhance its functionality. The pump’s design allows for efficient fuel delivery, which is crucial for optimal engine operation 3.

Benefits

Utilizing the Cummins 3929602 Fuel Injection Pump offers several advantages, including improved fuel efficiency, enhanced engine performance, and increased reliability. The pump’s precise fuel delivery helps to optimize combustion, which can lead to better fuel economy and reduced emissions. Additionally, its robust construction and advanced features contribute to the longevity and dependability of the engine 1.

Operational Mechanism

The Cummins 3929602 Fuel Injection Pump operates through a series of processes that include fuel pressurization, injection timing, and the interaction of various components within the pump. Fuel is drawn into the pump, pressurized, and then injected into the engine cylinders at specific intervals. The pump’s components work in concert to ensure that fuel is delivered in the correct quantity and at the optimal time for combustion 2.

Integration with Engine Management Systems

The Cummins 3929602 Fuel Injection Pump is designed to integrate seamlessly with modern engine management systems. It features electronic controls and sensors that allow it to communicate with the engine’s computer, enabling real-time adjustments to fuel delivery based on engine load, speed, and other operating conditions. This integration enhances the pump’s performance and contributes to the overall efficiency of the engine 3.

Common Issues and Troubleshooting

Like any mechanical component, the Cummins 3929602 Fuel Injection Pump may encounter issues such as leaks, misfires, or irregular engine performance. Troubleshooting these problems often involves inspecting the pump for signs of wear or damage, checking the fuel lines for leaks, and ensuring that the electronic controls are functioning correctly. Regular maintenance and prompt attention to any issues can help to prevent more serious problems down the line 2.

Maintenance and Service

Regular maintenance of the Cummins 3929602 Fuel Injection Pump is important to ensure its continued reliable operation. This includes recommended inspection intervals, cleaning procedures to remove any contaminants that may affect performance, and the replacement of wear parts as needed. Adhering to a maintenance schedule can help to extend the life of the pump and maintain engine performance 1.

Cummins Corporation

Cummins Inc. is a well-established manufacturer in the automotive industry, known for its wide range of diesel engine components and its commitment to innovation and quality. The company has a long history of producing reliable and high-performance parts, and the Cummins 3929602 Fuel Injection Pump is a testament to its dedication to advancing diesel engine technology 3.

Cummins Fuel Injection Pump 3929602 Compatibility

The Cummins Fuel Injection Pump part number 3929602 is a critical component designed to ensure efficient and reliable fuel delivery in various engine configurations. This part is engineered to fit seamlessly with several Cummins engines, ensuring optimal performance and longevity.

Engine Compatibility

-

6B5.9 Series

- The 3929602 fuel injection pump is specifically designed to integrate with the 6B5.9 engine series. This engine is known for its robust performance and is commonly used in heavy-duty applications. The pump’s design ensures precise fuel metering, which is crucial for maintaining the engine’s power output and efficiency.

-

Other Cummins Engines

- While the primary focus is on the 6B5.9 series, the 3929602 fuel injection pump is also compatible with other Cummins engines. This versatility makes it a valuable component for various applications, ensuring that the engine receives the correct amount of fuel for optimal operation.

Installation and Integration

The installation of the Cummins Fuel Injection Pump 3929602 is a straightforward process, designed to fit seamlessly into the engine’s fuel system. The pump is engineered to work with the engine’s existing components, ensuring a smooth and efficient fuel delivery system. Proper installation is crucial for maintaining the engine’s performance and reliability 2.

Integration of Part 3929602 Fuel Injection Pump with Engine Systems

The Part 3929602 Fuel Injection Pump is a sophisticated component that works in concert with several other engine systems to ensure optimal fuel delivery and engine performance.

When integrated with the Base Fuel Pump, the Fuel Injection Pump receives pressurized fuel. The Base Fuel Pump is responsible for drawing fuel from the tank and delivering it to the Fuel Injection Pump at the necessary pressure. This pressurized fuel is then further refined and metered by the Fuel Injection Pump to meet the engine’s demands under varying conditions.

The Fuel Pump Solenoid plays a significant role in the operation of the Fuel Injection Pump. This solenoid controls the flow of fuel to the pump by opening and closing the fuel passage. When the solenoid is activated, it allows fuel to flow into the Fuel Injection Pump, enabling it to begin the injection process. The precise control offered by the solenoid ensures that fuel delivery is both timely and accurate, which is essential for maintaining engine efficiency and performance.

Additionally, the Fuel Shutoff Valve is an integral component in the system. This valve is designed to cut off the fuel supply to the engine when necessary, such as during engine shutdown or in emergency situations. The Fuel Injection Pump must work in harmony with the Fuel Shutoff Valve to ensure a seamless transition when the valve is engaged. This coordination helps prevent fuel wastage and ensures that the engine can be safely and efficiently shut down.

Together, these components form a cohesive system that relies on the Fuel Injection Pump to deliver the right amount of fuel at the right time, ensuring the engine operates smoothly and efficiently 3.

Conclusion

The Cummins 3929602 Fuel Injection Pump is a critical component in diesel engine systems, offering precise fuel delivery, enhanced engine performance, and reliable operation. Its integration with modern engine management systems and compatibility with various Cummins engines make it a valuable asset for maintaining optimal engine efficiency and longevity.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.