This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

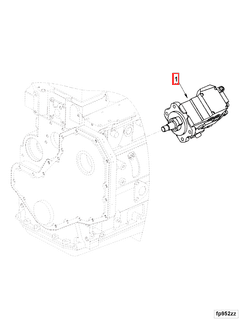

The Cummins 3946371 Fuel Injection Pump is a critical component designed for use in commercial trucks. It ensures efficient fuel delivery to the engine, contributing to the performance and reliability of diesel engines in heavy-duty applications. This part is integral to the broader fuel system, which is essential for optimal engine operation .

Basic Concepts of Fuel Injection Pumps

A fuel injection pump delivers fuel to the engine’s combustion chambers by pressurizing it and injecting it at precise moments to optimize combustion. In diesel engines, this component ensures that fuel is delivered at the correct pressure and timing, which is vital for efficient engine operation . There are two primary types of fuel injection systems: mechanical and electronic. Mechanical systems use physical components and cam-driven mechanisms to control fuel delivery, whereas electronic systems employ sensors and computer controls to manage injection timing and quantity .

Purpose and Function of the 3946371 Fuel Injection Pump

The Cummins 3946371 Fuel Injection Pump is designed to enhance the fuel delivery process in commercial trucks. It ensures that fuel is pressurized and delivered to the engine’s injectors at the optimal time and pressure. This precise fuel delivery contributes to better engine performance, increased fuel efficiency, and reduced emissions. The pump works in conjunction with other components of the fuel system to maintain consistent engine operation under varying load conditions .

Key Features

The Cummins 3946371 Fuel Injection Pump features advanced components that ensure reliable operation in demanding environments. It is constructed with high-quality materials to withstand heavy-duty use and includes precision-machined parts that enhance its accuracy and durability. Its robust build and efficient fuel delivery system distinguish it from other fuel injection pumps .

Benefits of Using the 3946371 Fuel Injection Pump

Utilizing the Cummins 3946371 Fuel Injection Pump offers several advantages. It provides improved fuel efficiency, which is crucial for reducing operating costs in commercial trucking. The pump also enhances engine performance by ensuring precise fuel delivery, leading to smoother operation and increased power output. Furthermore, its reliable design contributes to the overall durability and longevity of the engine, making it a valuable component for fleet operators .

Installation and Integration

Proper installation of the Cummins 3946371 Fuel Injection Pump is vital for ensuring its effective operation. It should be integrated into the truck’s engine system following manufacturer guidelines to ensure compatibility and optimal performance. Considerations for installation include proper alignment, secure mounting, and correct connection to the fuel lines and engine components. Attention to these details during installation will help prevent issues and ensure the pump functions as intended .

Maintenance and Service

Routine maintenance and service are essential for the longevity and optimal performance of the Cummins 3946371 Fuel Injection Pump. Regular inspections should be conducted to check for wear and tear on components. Cleaning the pump and replacing filters as needed will help maintain its efficiency. Additionally, following the manufacturer’s recommended service intervals for more comprehensive maintenance tasks will ensure the pump continues to operate reliably .

Troubleshooting Common Issues

Common problems associated with fuel injection pumps can include irregular fuel delivery, decreased engine performance, and increased emissions. Symptoms such as hard starting, misfires, or a decrease in power output may indicate issues with the pump. Potential causes can range from clogged fuel filters to worn-out pump components. Troubleshooting steps should include checking fuel lines for leaks, inspecting the pump for physical damage, and ensuring all connections are secure. Addressing these issues promptly can help maintain the pump’s performance and prevent further complications .

Performance Enhancements

There are several ways to enhance the performance of the Cummins 3946371 Fuel Injection Pump. Upgrades such as high-performance injectors or precision-machined components can improve fuel delivery and engine efficiency. Additionally, ensuring the pump is part of a well-maintained fuel system, including clean fuel and properly functioning sensors, can contribute to overall engine performance. These enhancements can lead to better fuel economy, increased power, and reduced emissions .

Cummins Corporation Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes a wide range of power solutions. Founded in 1919, the company has a long-standing reputation for innovation and quality in the commercial truck industry. Cummins offers a comprehensive product range, including engines, filtration systems, and fuel systems, designed to meet the demanding needs of heavy-duty applications. The company’s commitment to excellence and customer satisfaction has established it as a trusted name in the industry .

Role of Part 3946371 Fuel Injection Pump in Engine Systems

The 3946371 Fuel Injection Pump is integral to the efficient operation of engine systems by ensuring precise fuel delivery. This component interfaces with several key systems and components within the engine, optimizing performance and fuel economy .

Interaction with the Common Rail System

In engines equipped with a common rail fuel system, the Fuel Injection Pump plays a significant role in maintaining consistent fuel pressure. It works in conjunction with the high-pressure fuel pump to deliver fuel to the common rail, where it is stored under high pressure. The pump ensures that the fuel injectors receive a steady supply of pressurized fuel, allowing for precise control over the injection timing and quantity .

Coordination with Fuel Injectors

The Fuel Injection Pump is directly linked to the fuel injectors. It provides the necessary pressure to atomize the fuel into fine particles as it is injected into the combustion chamber. This atomization is essential for efficient combustion, reducing emissions, and enhancing engine performance. The pump’s ability to deliver fuel at the right pressure and timing is vital for the injectors to function correctly .

Integration with the Engine Control Unit (ECU)

The Fuel Injection Pump operates in close coordination with the Engine Control Unit (ECU). The ECU monitors various engine parameters such as load, speed, and temperature, and adjusts the fuel delivery accordingly. The pump responds to signals from the ECU, modulating the fuel pressure and flow to meet the engine’s demands under different operating conditions .

Relationship with the Fuel Filter and Fuel Tank

Upstream of the Fuel Injection Pump, the fuel filter plays a role in removing impurities from the fuel before it reaches the pump. Clean fuel ensures the pump operates efficiently and prolongs its lifespan. Downstream, the fuel tank supplies the raw fuel that the pump pressurizes. The pump draws fuel from the tank, filters it, and then delivers it to the injection system .

Impact on Combustion Efficiency

By ensuring precise fuel delivery, the Fuel Injection Pump directly influences combustion efficiency. Proper fuel atomization and timing lead to more complete combustion, which translates to better fuel economy and reduced emissions. The pump’s role in maintaining optimal fuel pressure is therefore fundamental to the overall efficiency of the engine .

Influence on Engine Performance

The performance of the engine is significantly affected by the Fuel Injection Pump. Consistent fuel pressure and precise delivery contribute to smooth engine operation, reduced knocking, and improved throttle response. The pump’s reliability and efficiency are key factors in maintaining high engine performance standards .

Conclusion

The Cummins 3946371 Fuel Injection Pump is a vital component that interacts with various engine systems to ensure optimal fuel delivery, enhancing both performance and efficiency. Its precise fuel delivery, robust design, and integration with other engine components make it an essential part of the fuel system in commercial trucks .

: Khajepour, A. (2023). *Synthesis Lectures on Advances in Automotive Technology*. Springer.

: Ribbens, W. B. (2003). *Understanding Automotive Electronics*. Elsevier Science.

: Stone, R. (2012). *Introduction to Internal Combustion Engines, Fourth Edition*. Macmillan.SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.