This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction to Cummins 3968188 Fuel Transfer Pump

Cummins, a leader in the automotive and heavy-duty truck industry, offers high-quality engine components, including the Cummins 3968188 Fuel Transfer Pump. This part is essential for commercial trucks, ensuring engines receive a consistent fuel supply for optimal performance and efficiency. Designed to meet the demanding requirements of commercial truck engines, the 3968188 model ensures reliable fuel delivery under various operating conditions 1.

Basic Concepts of a Fuel Transfer Pump

A fuel transfer pump moves fuel from the tank to the engine’s fuel system, ensuring it is delivered at the correct pressure and flow rate for efficient combustion. There are two primary types: mechanical and electric. The Cummins 3968188 is an electric pump, offering precise control over fuel delivery. It operates through suction and delivery mechanisms, drawing fuel from the tank and delivering it to the engine’s fuel injection system 2.

Purpose and Role of the Cummins 3968188 Fuel Transfer Pump

The Cummins 3968188 Fuel Transfer Pump is designed for commercial trucks, particularly those with Cummins engines. Reliable fuel transfer is vital for engine performance, ensuring the fuel injection system receives a consistent supply. The 3968188 model contributes to overall truck efficiency by providing stable and precise fuel delivery, essential for maintaining engine power and reducing fuel consumption. Its robust design and high-quality construction make it well-suited for the demanding conditions encountered in commercial trucking 3.

Detailed Operation of the Cummins 3968188 Fuel Transfer Pump

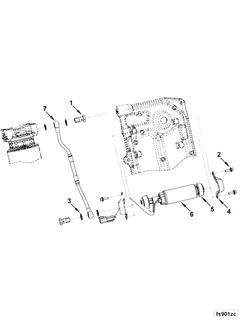

The Cummins 3968188 Fuel Transfer Pump comprises several key components, including the pump body, inlet and outlet ports, and internal components such as impellers and seals. The pump operates on the principle of centrifugal force, where the impeller spins to create a vacuum that draws fuel from the tank through the inlet port. The fuel is then pressurized and delivered to the engine through the outlet port. Pressure regulation and flow control are achieved through the pump’s internal mechanisms, ensuring that the fuel is delivered at the optimal pressure and rate for efficient engine operation 4.

Troubleshooting Common Issues with the Cummins 3968188 Fuel Transfer Pump

Common issues with the Cummins 3968188 Fuel Transfer Pump include leaks, cavitation, and inadequate fuel flow. Identifying these problems early is crucial for maintaining engine performance. Leaks can often be traced to worn seals or gaskets, while cavitation may indicate air in the fuel lines or a blocked filter. Inadequate fuel flow could be due to a clogged fuel filter or a malfunctioning pump. A step-by-step troubleshooting guide involves checking for visible leaks, ensuring the fuel lines are free of obstructions, and verifying that the pump is receiving power. If issues persist, consulting a professional is recommended to prevent further damage to the engine 5.

Maintenance Tips for the Cummins 3968188 Fuel Transfer Pump

Regular maintenance is essential for ensuring the longevity and reliability of the Cummins 3968188 Fuel Transfer Pump. This includes inspecting seals and gaskets for wear, cleaning the pump and fuel lines to prevent contamination, and lubricating moving parts to reduce friction. Preventive measures such as avoiding fuel contamination and proper storage of the vehicle can also extend the pump’s life. A recommended maintenance schedule should be followed, which typically includes periodic inspections and replacements of worn components 6.

Cummins’ Commitment to Quality and Innovation

Cummins is renowned for its commitment to quality and innovation in engineering and manufacturing processes. The company continually invests in research and development to enhance the performance and reliability of its components, including fuel transfer pumps. Cummins’ support and resources for technicians and fleet operators are extensive, providing access to technical assistance, training programs, and detailed documentation to ensure that professionals can maintain and troubleshoot their equipment effectively 7.

Expert Insights and Best Practices

Industry experts emphasize the importance of fuel transfer pumps in maintaining engine performance and efficiency. Best practices for installation and usage include following manufacturer guidelines, using high-quality fuel, and performing regular maintenance checks. Real-world examples and case studies demonstrate the impact of proper fuel transfer pump maintenance on engine longevity and fuel efficiency 8.

Conclusion

The Cummins 3968188 Fuel Transfer Pump is a critical component in commercial trucks, ensuring reliable and efficient fuel delivery to the engine. Understanding its function, maintenance requirements, and troubleshooting procedures is essential for mechanics and engineers to maintain optimal performance. Proper maintenance and timely troubleshooting are key to extending the life of the pump and ensuring the engine operates at peak efficiency.

Cummins Fuel Transfer Pump 3968188 Compatibility

The Cummins Fuel Transfer Pump, part number 3968188, is a critical component in the fuel system of various Cummins engines. This part is designed to ensure a steady and efficient transfer of fuel from the fuel tank to the engine, which is essential for maintaining optimal engine performance and reliability.

Compatibility with Cummins Engines

The 3968188 Fuel Transfer Pump is compatible with a wide range of Cummins engines, including:

- 6C8.3

- ISB CM850

- ISC CM2150

- ISC CM850

- ISC8.3 CM2250

- ISL CM2150

- ISL9 CM2150 SN

- ISL9 CM2250

- ISL9.5 CM2880 L138

- QSB4.5 CM850 (CM2850)

- QSB5.9 CM850

- QSB6.7 CM850 (CM2850)

- QSC8.3 CM850 (CM2850)

- QSC9 CM2250 / QSL9 CM2250

- QSL8.9 CM2150 L141

- QSL9 CM2250

- QSL9 CM2350 L102

- QSL9 CM850 (CM2850)

Grouping of Compatible Engines

- ISC Series: ISC CM2150, ISC CM850, ISC8.3 CM2250

- ISL Series: ISL CM2150, ISL9 CM2150 SN, ISL9 CM2250, ISL9.5 CM2880 L138

- QSB Series: QSB4.5 CM850 (CM2850), QSB5.9 CM850, QSB6.7 CM850 (CM2850)

- QSC and QSL Series: QSC8.3 CM850 (CM2850), QSC9 CM2250 / QSL9 CM2250, QSL8.9 CM2150 L141, QSL9 CM2250, QSL9 CM2350 L102, QSL9 CM850 (CM2850)

- ISB Series: ISB CM850

This compatibility ensures that the 3968188 Fuel Transfer Pump can be used across various models and configurations of Cummins engines, providing a reliable solution for maintaining fuel flow and engine performance 9.

Role of Part 3968188 Fuel Transfer Pump in Engine Systems

The Fuel Transfer Pump (part 3968188) is an integral component in modern engine systems, working in conjunction with several other parts to ensure efficient and reliable fuel delivery.

When integrated with an Electronic Control Cooler (ECC), the Fuel Transfer Pump enhances the overall performance of the fuel system. The ECC regulates the temperature of the electronic control module, ensuring it operates within optimal parameters. The Fuel Transfer Pump, in this context, provides a consistent fuel supply, which is essential for the ECC to maintain stable control signals. This synergy between the pump and the cooler ensures that the engine receives a precise amount of fuel, tailored to the current operating conditions, thus optimizing both performance and fuel efficiency.

In combination with a Lift Pump Kit, the Fuel Transfer Pump plays a significant role in pre-pressurizing the fuel before it reaches the high-pressure injection system. The Lift Pump Kit typically includes components such as a pre-filter, which removes contaminants from the fuel, and a priming pump, which ensures the system is free of air before engine start-up. The Fuel Transfer Pump works in tandem with these components to maintain a steady fuel flow, reducing the load on the high-pressure pump and enhancing the overall reliability of the fuel system.

Together, these components create a robust fuel delivery system that not only meets the demands of modern engines but also contributes to their longevity and efficiency. The Fuel Transfer Pump’s role in this ecosystem is to ensure that fuel is delivered smoothly and consistently, supporting the functions of the ECC and the Lift Pump Kit 10.

-

Bonneau, D., Fatu, A., & Souchet, D. (2014). Internal Combustion Engine Bearings Lubrication in Hydrodynamic Bearings. Wiley-ISTE.

↩ -

Hu, H., Smaling, R., & Baseley, S. (2014). Heavy-Duty Wheeled Vehicles. SAE International.

↩ -

Mollenhauer, K., & Tschoeke, H. (2010). Handbook of Diesel Engines. Springer.

↩ -

Pulkrabek, W. W. (2014). Engineering Fundamentals of the Internal Combustion Engine. Pearson Education.

↩ -

Cummins Inc. (n.d.). Owners Manual for L9 CM2350 L129C. Bulletin Number 5579687.

↩ -

Cummins Inc. (n.d.). Owners Manual for L9 CM2350 L129C. Bulletin Number 5579687.

↩ -

Cummins Inc. (n.d.). Owners Manual for L9 CM2350 L129C. Bulletin Number 5579687.

↩ -

Cummins Inc. (n.d.). Owners Manual for L9 CM2350 L129C. Bulletin Number 5579687.

↩ -

Cummins Inc. (n.d.). Owners Manual for L9 CM2350 L129C. Bulletin Number 5579687.

↩ -

Cummins Inc. (n.d.). Owners Manual for L9 CM2350 L129C. Bulletin Number 5579687.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.