This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

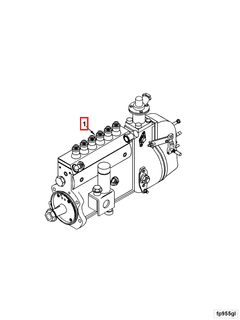

The Cummins 4063209 Fuel Injection Pump is a vital component in the operation of commercial trucks. It is responsible for delivering precise amounts of fuel to the engine, ensuring efficient combustion and optimal performance. This part is integral to the overall functionality of diesel engines, particularly in heavy-duty applications where reliability and efficiency are paramount.

Basic Concepts of Fuel Injection Pumps

A fuel injection pump is a device that pressurizes and delivers fuel to the engine’s combustion chambers. In diesel engines, this pump plays a role in ensuring that fuel is injected at the right time and in the correct quantity. There are two primary types of fuel injection systems: mechanical and electronic. Mechanical systems rely on physical components and cam-driven mechanisms to control fuel delivery, while electronic systems use sensors and computer controls to achieve greater precision and efficiency.

Purpose and Function of the Cummins 4063209 Fuel Injection Pump

The Cummins 4063209 Fuel Injection Pump is designed to deliver fuel to the engine under high pressure. It ensures that the fuel is atomized properly, which enhances combustion efficiency. By providing the engine with a consistent and precise fuel supply, this pump helps maintain engine performance, reduce emissions, and improve fuel economy 1.

Key Features

The Cummins 4063209 Fuel Injection Pump features a robust design that includes high-quality construction materials. It is built to withstand the demanding conditions of commercial truck operations. Key attributes include precision engineering, durable components, and a design that promotes longevity and reliable performance. These features contribute to the pump’s ability to deliver consistent fuel pressure and flow.

Benefits of Using the Cummins 4063209 Fuel Injection Pump

Utilizing the Cummins 4063209 Fuel Injection Pump offers several advantages. It contributes to improved fuel efficiency by ensuring that fuel is delivered precisely when needed. This results in better engine performance and reduced fuel consumption 2. Additionally, the pump’s reliable operation enhances the overall durability and longevity of the engine, providing commercial truck operators with a dependable component for their vehicles.

Installation and Integration

Proper installation of the Cummins 4063209 Fuel Injection Pump is important for ensuring it functions correctly within the truck’s fuel system. This process involves several steps, including preparing the fuel lines, mounting the pump securely, and connecting it to the engine’s fuel system. Careful attention to these steps ensures that the pump is integrated seamlessly and operates efficiently.

Maintenance and Care

Routine maintenance is important for keeping the Cummins 4063209 Fuel Injection Pump in optimal condition. This includes regular inspections to check for wear and tear, cleaning the pump to remove any contaminants, and replacing wear parts as needed. Adhering to a maintenance schedule helps prevent issues and ensures the pump continues to operate efficiently.

Troubleshooting Common Issues

Common problems with the Cummins 4063209 Fuel Injection Pump may include irregular fuel delivery, leaks, or decreased engine performance. Troubleshooting these issues involves checking the fuel lines for blockages, inspecting the pump for wear, and ensuring all connections are secure. Identifying and addressing these problems promptly can help maintain the pump’s efficiency and reliability.

Performance Enhancements

There are several ways to enhance the performance of the Cummins 4063209 Fuel Injection Pump. This may include tuning the pump for better fuel delivery, using higher-quality fuel filters to ensure clean fuel, and regularly maintaining the pump to prevent issues. These enhancements can lead to improved engine performance and fuel efficiency 3.

Safety Considerations

When working with the Cummins 4063209 Fuel Injection Pump, it is important to observe safety guidelines to prevent accidents. This includes wearing appropriate personal protective equipment, ensuring the engine is off before performing maintenance, and following all manufacturer recommendations for handling and installation. Adhering to these safety practices ensures a safe working environment.

Environmental Impact

The use of the Cummins 4063209 Fuel Injection Pump contributes to reduced emissions and improved fuel efficiency. By ensuring precise fuel delivery, the pump helps minimize waste and enhance combustion efficiency. This not only benefits the environment by reducing harmful emissions but also promotes more sustainable operation of commercial trucks.

Cummins Corporation Overview

Cummins Inc. is a renowned manufacturer of diesel engines and related components. With a history of innovation and excellence, Cummins has established a strong reputation in the industry. The company’s expertise in engine technology and commitment to quality are reflected in their products, including the Cummins 4063209 Fuel Injection Pump.

Conclusion

The Cummins 4063209 Fuel Injection Pump is a critical component for the efficient and reliable operation of diesel engines in commercial trucks. Its precise fuel delivery, robust design, and compatibility with various engine models make it an essential part of the fuel system. Proper installation, maintenance, and adherence to safety guidelines ensure optimal performance and longevity of the pump, contributing to improved engine efficiency and reduced environmental impact.

-

Isermann, R. (2017). Combustion Engine Diagnosis. Springer Vieweg.

↩ -

Hilgers, M. (2023). Fuel Consumption and Consumption Optimization, Second Edition. Springer Nature.

↩ -

Brown Jr, A. (2010). Technologies and Approaches to Reducing the Fuel Consumption of Medium and Heavy-Duty Vehicles. National Academy of Sciences.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.