This is an oversize product. Additional shipping fees may apply.

This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

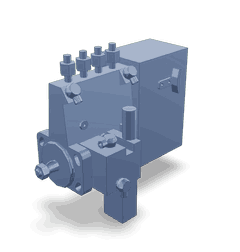

The Cummins 5335177 Fuel Injection Pump is a component designed for commercial trucks, aimed at enhancing diesel engine performance and efficiency. This part is integral to the operation of these vehicles, ensuring optimal fuel delivery to the engine.

Basic Concepts of Fuel Injection Pumps

A fuel injection pump pressurizes fuel and delivers it to the engine’s combustion chambers at precise moments. In diesel engines, this pump ensures fuel is injected at the correct pressure and timing, crucial for efficient combustion and engine performance 1. It operates using mechanical or electronic controls to regulate fuel injection.

Purpose of the Cummins 5335177 Fuel Injection Pump

The Cummins 5335177 Fuel Injection Pump delivers fuel to the engine at the precise timing and pressure required for optimal combustion. This ensures correct fuel atomization, enhancing the mixing of fuel and air for more efficient burning and improved engine performance. It maintains the balance between fuel delivery and engine demand, vital for commercial trucks’ variable operating conditions.

Key Features

This Cummins part is characterized by its robust design and high-quality materials, ensuring durability and reliability. It incorporates advanced features such as precise fuel metering and electronic controls for fine-tuning fuel delivery. These features contribute to the pump’s ability to meet the demanding requirements of commercial truck engines.

Benefits

The benefits of the Cummins 5335177 Fuel Injection Pump include improved fuel efficiency, enhanced engine performance, and increased reliability. By ensuring optimal fuel delivery pressure and timing, this pump maximizes engine power output while minimizing fuel consumption. Its robust construction and advanced features contribute to its longevity and consistent performance under various operating conditions.

Installation and Integration

Installing the Cummins 5335177 Fuel Injection Pump involves integrating it into the truck’s engine system, which may require specific modifications or considerations to ensure compatibility with the engine’s fuel system. Proper installation is crucial to maintain the pump’s performance and efficiency and should be carried out by qualified professionals to ensure all connections and adjustments are correctly made.

Troubleshooting and Maintenance

Common issues with the Cummins 5335177 Fuel Injection Pump may include fuel delivery inconsistencies or pump wear. Troubleshooting these issues involves checking for proper fuel pressure, inspecting the pump for signs of wear, and ensuring all connections are secure. Regular maintenance practices, such as cleaning and inspecting the pump, can help prevent issues and ensure optimal performance.

Performance and Efficiency

The Cummins 5335177 Fuel Injection Pump contributes to the overall performance and efficiency of the truck by ensuring fuel is delivered to the engine in a manner that optimizes combustion. This results in improved fuel economy and power output, critical factors in the operation of commercial trucks. The pump’s precise fuel delivery also helps reduce emissions, contributing to cleaner and more efficient engine operation.

Safety Considerations

When operating and maintaining the Cummins 5335177 Fuel Injection Pump, it is important to follow safety procedures to prevent accidents and ensure the longevity of the pump. This includes handling the pump with care, using the appropriate tools for installation and maintenance, and adhering to safety guidelines when working with fuel systems. Proper training and awareness of safety precautions are essential for anyone involved in the maintenance of this component.

Cummins Overview

Cummins Inc. is a well-established company with a long history in the commercial truck industry. Known for its commitment to quality and innovation, Cummins has built a reputation for producing reliable and high-performance diesel engines and components. The company’s expertise in engine technology is reflected in its range of products, including the Cummins 5335177 Fuel Injection Pump, designed to meet the rigorous demands of commercial truck applications.

Cummins Fuel Injection Pump 5335177 Compatibility

The Cummins Fuel Injection Pump part number 5335177 is designed to be compatible with a range of engine models, ensuring reliable performance and efficient fuel delivery. This part is engineered to meet the specific needs of various Cummins engines, providing precise control over fuel injection timing and quantity.

B3.3 Engine Group

The Cummins B3.3 engine series is one of the key beneficiaries of the 5335177 Fuel Injection Pump. This engine series is known for its robust design and versatility, making it suitable for various applications, including agricultural, industrial, and marine uses. The 5335177 part is meticulously crafted to integrate seamlessly with the B3.3 engines, enhancing their operational efficiency and longevity.

The compatibility of the 5335177 Fuel Injection Pump with the B3.3 engine series is a testament to Cummins’ commitment to quality and performance. This part ensures that the engine operates at peak efficiency, delivering the power and reliability that users expect from Cummins engines.

Role of Part 5335177 Fuel Injection Pump in Engine Systems

The 5335177 Fuel Injection Pump is an integral component in the fuel delivery system of an engine, ensuring precise and efficient fuel distribution. This pump works in conjunction with several other components to maintain optimal engine performance.

Interaction with the Fuel System

-

Fuel Tank: The pump draws fuel from the tank, where it is stored under pressure. This ensures a consistent supply of fuel to the engine, regardless of the vehicle’s orientation or fuel level.

-

Fuel Filter: Before the fuel reaches the injection pump, it passes through the fuel filter. This component removes impurities and contaminants, ensuring that only clean fuel enters the pump. This protects the delicate internal mechanisms of the pump from wear and damage.

-

Fuel Lines: The pump is connected to the fuel lines, which transport the pressurized fuel from the pump to the injectors. These lines must be robust and leak-free to maintain the integrity of the fuel system.

Coordination with Engine Components

-

Injectors: The pressurized fuel from the pump is delivered to the injectors, which atomize the fuel into the combustion chamber. The precise timing and quantity of fuel injection are controlled by the pump, ensuring efficient combustion and power delivery.

-

Engine Control Unit (ECU): The ECU monitors various engine parameters and adjusts the fuel injection timing and quantity accordingly. The fuel injection pump must be capable of responding to these signals to maintain optimal engine performance under varying conditions.

-

Camshaft and Crankshaft Sensors: These sensors provide the ECU with data on the engine’s rotational speed and position. The fuel injection pump uses this information to time the fuel delivery accurately, enhancing engine efficiency and reducing emissions.

Performance and Efficiency

The 5335177 Fuel Injection Pump plays a significant role in the overall performance and efficiency of the engine. By ensuring a consistent and precise fuel supply, it contributes to smooth engine operation, improved fuel economy, and reduced emissions. The pump’s ability to adapt to changing engine conditions, in coordination with the ECU and other components, is essential for maintaining optimal engine performance.

Conclusion

The Cummins 5335177 Fuel Injection Pump is a critical component for commercial trucks, designed to enhance engine performance and efficiency. Its robust design, advanced features, and precise fuel delivery contribute to improved fuel economy, power output, and reduced emissions. Proper installation, maintenance, and adherence to safety procedures are essential for ensuring the longevity and optimal performance of this part.

-

Schneider, Wolf-Henning. Pistons and Engine Testing. Springer Nature, 2016.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.