This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

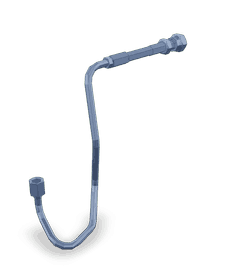

The Cummins 5367099 Crankshaft Pulley is a component designed for use in commercial trucks equipped with Cummins engines. This pulley plays a role in the operation of these vehicles by facilitating the transfer of power from the engine to various accessories. Understanding its function and importance can help in maintaining the efficiency and reliability of the truck’s engine system.

Basic Concepts of Crankshaft Pulleys

A crankshaft pulley, also known as a harmonic balancer, is a component attached to the front of an engine’s crankshaft. Its primary function is to drive various engine accessories through a series of belts or chains. These accessories may include the alternator, water pump, and air conditioning compressor, among others. The pulley helps in reducing vibrations caused by the engine’s operation, ensuring smoother and more efficient performance 1.

Purpose of the 5367099 Crankshaft Pulley

This Cummins part is specifically designed to integrate with Cummins engines found in commercial trucks. It plays a role in driving engine accessories by transferring rotational force from the crankshaft. This ensures that critical components such as the alternator and water pump operate efficiently. The pulley also contributes to reducing engine vibrations, which can enhance the overall performance and longevity of the engine 2.

Key Features

The 5367099 is engineered with several key features that enhance its performance and durability. It is constructed from high-quality materials that can withstand the rigors of commercial truck operation. The design includes a dampening element that helps in reducing vibrations, contributing to a smoother engine operation. Additionally, the pulley is precision-machined to ensure accurate fitment and optimal performance 3.

Benefits

The use of the 5367099 offers several benefits. It contributes to improved engine efficiency by ensuring that engine accessories receive the necessary power to operate effectively. The reduction in vibrations can lead to a more stable engine performance, which may result in increased reliability and longevity of the engine components. Additionally, the high-quality materials and precise engineering of the pulley enhance its durability, making it a robust choice for commercial truck applications 4.

Installation Process

Installing the 5367099 requires careful attention to detail to ensure proper fitment and function. The process involves removing the old pulley, if present, and aligning the new pulley with the crankshaft. Tools such as a pulley puller and torque wrench may be necessary. It is important to follow the manufacturer’s guidelines to ensure that the pulley is installed correctly and securely.

Common Issues and Troubleshooting

Common issues with the 5367099 may include wear, misalignment, or damage. Signs of these issues can include unusual engine vibrations, noise, or a decrease in the performance of engine accessories. Troubleshooting may involve inspecting the pulley for signs of wear or damage, ensuring proper alignment, and replacing the pulley if necessary. Regular maintenance can help in identifying and addressing these issues before they lead to more significant problems.

Maintenance Tips

To ensure the optimal performance and longevity of the 5367099, regular maintenance is recommended. This includes inspecting the pulley for signs of wear or damage, ensuring that it is properly aligned, and replacing it if necessary. Additionally, keeping the pulley clean and free from debris can help in maintaining its efficiency. Following the manufacturer’s guidelines for maintenance can contribute to the overall reliability of the engine system.

Cummins Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes a wide range of power solutions, including engines, filtration, and emissions control technologies. With a history spanning over a century, Cummins has established a reputation for quality, reliability, and innovation in the commercial truck industry. The company’s product range includes engines for on-highway and off-highway applications, as well as components and systems that enhance the performance and efficiency of these engines.

Compatibility of Crankshaft Pulley Part 5367099

The Cummins crankshaft pulley part number 5367099 is designed to fit seamlessly with several engine models, ensuring optimal performance and reliability. This part is integral to the engine’s operation, as it interfaces with the crankshaft to drive the engine’s ancillary systems.

QSB6.7 M CM2250 Engines

The part 5367099 is specifically engineered to fit the QSB6.7 M CM2250 engines. These engines are known for their robust design and efficiency, making them suitable for a variety of applications, from industrial use to heavy-duty transportation. The crankshaft pulley’s precise fit ensures that it can handle the torque and rotational forces generated by these engines, contributing to their overall durability and performance.

Grouping of Engines

While the part 5367099 is explicitly designed for the QSB6.7 M CM2250 engines, it is essential to note that Cummins often designs parts to be compatible across similar engine models within the same series. This design philosophy ensures that maintenance and repair processes are streamlined, allowing for easier part sourcing and installation. For instance, other engines within the QSB series might also use similar crankshaft pulleys, provided they share the same specifications and design requirements.

Role of Part 5367099 Crankshaft Pulley in Engine Systems

The part 5367099 Crankshaft Pulley is integral to the efficient operation of several engine systems. It is primarily responsible for driving the engine’s accessories through the serpentine belt. Here’s how it interfaces with various components:

Accessory Drive System

The Crankshaft Pulley is the primary driver for the serpentine belt, which in turn powers multiple engine accessories. These accessories include:

- Alternator: The pulley ensures the alternator receives the necessary rotational force to generate electricity, which charges the battery and powers the electrical systems.

- Water Pump: By driving the water pump, the pulley helps maintain optimal engine temperature through efficient coolant circulation.

- Power Steering Pump: In systems equipped with a hydraulic power steering pump, the pulley provides the necessary drive to assist in steering operations.

- Air Conditioning Compressor: For engines with air conditioning, the pulley drives the compressor, enabling the cooling system to function.

Timing System

Although the Crankshaft Pulley is not directly part of the timing system, its consistent and smooth operation ensures that the crankshaft’s rotation is steady. This steadiness is essential for the proper synchronization of the camshaft and other timing components, indirectly influencing the engine’s overall performance and efficiency.

Fuel System

While the Crankshaft Pulley does not directly interact with the fuel filter, its role in driving the engine’s accessories indirectly supports the fuel system. A well-maintained and efficiently operating engine, powered by the pulley, ensures that the fuel system components, including the fuel filter, function under optimal conditions. This results in better fuel delivery and combustion efficiency.

Vibration Dampening

The Crankshaft Pulley often incorporates a harmonic balancer, which helps reduce vibrations caused by the engine’s reciprocating parts. This balancer ensures smoother operation of the engine, reducing wear on connected components and contributing to the longevity of the fuel filter and other parts by minimizing undue stress.

Conclusion

In summary, the part 5367099 Crankshaft Pulley is a key component that supports various engine systems by ensuring the reliable operation of driven accessories and maintaining engine smoothness, which indirectly benefits the fuel system and other critical components.

-

Minaker, Bruce P. Fundamentals of Vehicle Dynamics and Modelling. John Wiley & Sons, 2019.

↩ -

Lakshminarayanan, P. A., and Avinash Kumar. Design and Development of Heavy Duty Diesel Engines: A Handbook. Springer Nature, 2020.

↩ -

Rajamani, Rajesh. Vehicle Dynamics and Control. Springer, 2005.

↩ -

Boyce, Meherwan P. Gas Turbine Engineering Handbook 4th Edition. Butterworth-Heinemann, 2011.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.