This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

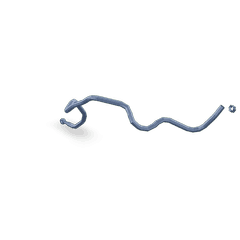

The Cummins 5440769 Fuel Drain Tube is a component designed for use in the fuel systems of commercial trucks. Its primary role is to facilitate the draining of fuel from the system, which is necessary for routine maintenance or in emergency situations. This part is integral to ensuring the fuel system operates efficiently and safely 1.

Purpose and Function

This Cummins part serves a specific function within the fuel system by allowing for the controlled release of fuel. This is particularly important during maintenance procedures where it is necessary to remove fuel for inspection or cleaning of the fuel tank and related components. Additionally, in emergency scenarios where fuel contamination is suspected, the drain tube provides a means to quickly and safely evacuate the fuel, minimizing potential damage to the engine and ensuring safety 2.

Key Features

The Fuel Drain Tube is constructed from durable materials that are resistant to the corrosive effects of fuel, ensuring longevity and reliable performance. Its design includes features such as a secure fitting mechanism to prevent leaks during operation and a straightforward drainage mechanism that allows for easy and efficient fuel removal. The tube’s construction and design are tailored to withstand the rigors of commercial truck operations, providing a robust solution for fuel system maintenance 3.

Benefits

Utilizing the 5440769 offers several advantages. It simplifies the process of fuel system maintenance by providing a dedicated pathway for fuel drainage, which can lead to more thorough and efficient inspections and cleanings. Additionally, the tube enhances safety during fuel draining procedures by offering a controlled method for fuel release, reducing the risk of spills and contamination. Furthermore, by facilitating easier and more effective maintenance, the tube can contribute to cost savings through efficient fuel management and reduced downtime.

Installation and Usage

Proper installation of this Cummins part is crucial for its effective operation. Installation should be performed according to the manufacturer’s guidelines, ensuring that all connections are secure and that the tube is correctly positioned within the fuel system. When using the tube for fuel drainage, it is important to follow safety protocols, including working in a well-ventilated area and ensuring that all ignition sources are eliminated to prevent the risk of fire or explosion. Regular checks should be performed to ensure the tube remains in good condition and functions as intended.

Troubleshooting and Maintenance

Common issues with the Fuel Drain Tube may include leaks or blockages. Troubleshooting should begin with a visual inspection of the tube and its connections for signs of wear or damage. If a leak is detected, the connections should be tightened or the tube replaced if necessary. Blockages can often be cleared by flushing the tube with a compatible solvent. Regular maintenance, including periodic inspections and cleaning, will help ensure the longevity and reliability of the tube.

Safety Considerations

When working with the Fuel Drain Tube, it is important to observe several safety considerations. Fuel is a flammable substance, and therefore, all work should be conducted in a well-ventilated area away from ignition sources. Appropriate personal protective equipment, such as gloves and safety glasses, should be worn to protect against fuel spills. Additionally, it is advisable to have fire extinguishing equipment readily available in case of emergencies.

Cummins Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes a wide range of power solutions, including engines, filtration, and emissions solutions. With a history spanning over a century, Cummins has established a reputation for quality, innovation, and reliability in the automotive and heavy-duty truck industries. The company’s commitment to excellence is reflected in its products, which are designed to meet the demanding requirements of commercial applications.

Role of Part 5440769 Fuel Drain Tube in Engine Systems

The 5440769 is an essential component in the fuel system of various engine setups. It is specifically designed to facilitate the safe and efficient drainage of fuel from the system. This component interfaces with several key elements within the engine system to ensure optimal performance and safety.

Integration with Plumbing Systems

In the context of engine plumbing, the Fuel Drain Tube is connected to the fuel lines and the fuel tank. Its primary function is to provide a controlled pathway for fuel to be drained from the system. This is particularly important during maintenance procedures or when the fuel needs to be changed. The tube is typically connected to a valve mechanism that allows the operator to open or close the drain as needed. This integration ensures that fuel can be safely removed without the risk of spills or contamination.

Functionality in Fuel Drain Systems

Within the fuel drain system, the Fuel Drain Tube plays a pivotal role. It is often connected to a collection container or a sump, where the drained fuel is collected for proper disposal or recycling. The tube is designed to handle the specific properties of the fuel, including its viscosity and potential for vaporization, ensuring that the drainage process is both efficient and safe.

The Fuel Drain Tube also works in conjunction with other components such as filters and sensors. Filters may be placed inline to catch any debris or contaminants that could otherwise enter the drainage system, while sensors can monitor the flow rate and detect any anomalies that might indicate a problem within the system.

Enhanced Safety and Efficiency

By providing a dedicated pathway for fuel drainage, the Fuel Drain Tube enhances the overall safety and efficiency of the engine system. It allows for routine maintenance to be performed with minimal risk, reducing the likelihood of fuel spills that could pose a fire hazard or environmental risk. Additionally, it ensures that the fuel system can be quickly and effectively drained when necessary, which is particularly important in emergency situations or during system upgrades.

Conclusion

In summary, the Cummins part number 5440769 is essential for the ISX15 CM2350 X101 and ISX15 CM2350 X116B engines, ensuring that the fuel system remains clean and free from contaminants. Its integration with plumbing and fuel drain systems allows for streamlined maintenance procedures and enhanced safety protocols.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.