5613501

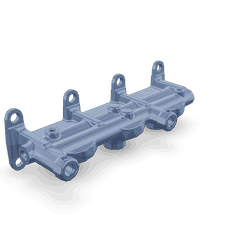

Fuel Filter Head

Cummins®

AVAILABLE

More than 10 are currently available

Ships within 2-4 business days

This is an oversize product. Additional shipping fees may apply.

This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

The Cummins 5613501 Check Valve is a component designed for use in commercial truck systems. Its purpose is to allow fluid to flow in one direction while preventing reverse flow, thereby maintaining system integrity and efficiency. This check valve is integral to the operation of various fluid systems within commercial trucks.

Basic Concepts of Check Valves

A check valve, also known as a non-return valve, is a mechanical device that permits fluid to flow through it in only one direction. It operates by using a movable element, such as a flap, ball, or spring-loaded plunger, which opens under the pressure of the fluid flow and closes when the flow stops or reverses. Check valves are commonly used in fluid systems to prevent backflow, which can cause damage or inefficiency in the system 1.

Operation of the 5613501 Check Valve

The Cummins 5613501 Check Valve functions by utilizing principles of fluid dynamics. When fluid flows in the correct direction, the valve opens, allowing the fluid to pass through. If the flow attempts to reverse, the valve closes, blocking the flow and preventing backflow. This mechanism relies on the pressure differential created by the fluid flow to operate effectively.

Purpose of the 5613501 Check Valve in Truck Systems

In commercial truck systems, the 5613501 Check Valve plays a role in maintaining the integrity and efficiency of fluid systems. By preventing reverse flow, it ensures that fluids move in the intended direction, which is vital for the proper operation of components such as fuel systems, hydraulic systems, and cooling systems. This helps in maintaining system performance and reducing the risk of damage due to backflow.

Key Features of the 5613501 Check Valve

The design and construction of the Cummins 5613501 Check Valve contribute to its performance and durability. It is built with high-quality materials that resist corrosion and wear, ensuring long-term reliability. The valve’s design includes a precise sealing mechanism that provides effective fluid control and minimizes the risk of leaks.

Benefits of Using the 5613501 Check Valve

The advantages of using the Cummins 5613501 Check Valve include improved system reliability, enhanced performance, and potential cost savings. By preventing backflow, the valve helps maintain consistent fluid pressure and flow, which can lead to more efficient system operation. Additionally, its durable construction reduces the need for frequent replacements, contributing to lower maintenance costs 2.

Installation Considerations

Proper installation of the Cummins 5613501 Check Valve is important for ensuring optimal performance and longevity. Guidelines for installation include ensuring the valve is correctly oriented to allow fluid flow in the intended direction, securing it firmly in place to prevent movement, and verifying that all connections are tight and leak-free. Following these best practices helps in achieving the valve’s full potential.

Troubleshooting Common Issues

Common problems associated with check valves can include leaks, failure to open or close properly, and blockages. Troubleshooting methods involve inspecting the valve for signs of wear or damage, checking the orientation and installation, and ensuring there are no obstructions in the fluid path. Addressing these issues promptly can help maintain system efficiency and prevent further complications.

Maintenance Tips

Routine maintenance practices for the Cummins 5613501 Check Valve include regular inspection intervals to check for wear, corrosion, or leaks. Cleaning the valve and its surrounding components can help prevent buildup that might affect its operation. Following these maintenance tips ensures the valve remains in good working condition and continues to provide reliable performance.

Cummins Corporation Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a history spanning over a century, Cummins has established a strong reputation in the commercial vehicle industry for producing high-quality, reliable components. The company’s product range includes engines, powertrains, and aftermarket parts, serving a variety of industries and applications 3.

Cummins Engine Part 5613501 Check Valve Compatibility

The Cummins part 5613501 Check Valve is a critical component in the engine systems of various Cummins engines. This check valve is designed to ensure the unidirectional flow of fluids, preventing backflow and maintaining system integrity. Below is a detailed description of how this part fits into the specified engines.

QSK38 Series

- QSK38 CM2150 MCRS

- QSK38 CM850 MCRS

The QSK38 series engines, including the CM2150 MCRS and CM850 MCRS variants, are equipped with the Cummins part 5613501 Check Valve. This valve is integral to the engine’s lubrication system, ensuring that oil flows in the correct direction and preventing any reverse flow that could compromise the system’s efficiency and longevity.

QSK50 Series

- QSK50 CM2150 K107

- QSK50 CM2150 MCRS

In the QSK50 series, both the CM2150 K107 and CM2150 MCRS engines utilize the Cummins part 5613501 Check Valve. This component is essential in maintaining the proper flow of fluids within the engine’s cooling and lubrication systems, ensuring optimal performance and reliability.

QSK60 Series

- QSK60 CM850 MCRS

The QSK60 CM850 MCRS engine also incorporates the Cummins part 5613501 Check Valve. This valve plays a crucial role in the engine’s hydraulic systems, ensuring that fluids move in the intended direction and preventing any backflow that could lead to system failures.

By integrating the Cummins part 5613501 Check Valve, these engines benefit from enhanced fluid management, which is critical for maintaining performance and extending the lifespan of the engine components.

Role of Part 5613501 Check Valve in Engine Systems

The 5613501 Check Valve is an essential component in maintaining the integrity and efficiency of fuel systems within various engine setups. Its primary function is to allow fuel to flow in one direction while preventing any backflow, which ensures consistent fuel pressure and delivery.

When integrated with the Fuel Filter, the 5613501 Check Valve works to maintain a stable fuel flow. The Fuel Filter is responsible for removing impurities and contaminants from the fuel before it reaches the engine. The check valve, positioned either before or after the filter depending on the system design, ensures that the filtered fuel moves toward the engine without any reverse flow. This setup helps in prolonging the filter’s lifespan by reducing the chances of contaminants being pushed back into it.

At the Fuel Filter Location, typically situated near the fuel tank or along the fuel lines, the 5613501 Check Valve plays a significant role. It ensures that the fuel, once filtered, is delivered efficiently to the engine components. This is particularly important in high-performance engines where fuel pressure and consistency are paramount for optimal combustion and power output.

In summary, the 5613501 Check Valve enhances the reliability and performance of the fuel system by ensuring unidirectional fuel flow, which is vital for the proper functioning of the Fuel Filter and maintaining overall system efficiency.

Conclusion

The Cummins 5613501 Check Valve is a vital component in commercial truck and engine systems, ensuring the unidirectional flow of fluids and preventing backflow. Its robust design, reliable performance, and compatibility with various Cummins engines make it an essential part for maintaining system integrity and efficiency. Proper installation, maintenance, and troubleshooting are key to maximizing the benefits of this part.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.