This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

The BM76454 Fuel Pump Damper, manufactured by Cummins, is designed to enhance the performance of heavy-duty truck fuel systems. Cummins, a prominent name in the commercial truck industry, produces a range of high-quality parts aimed at improving engine efficiency and reliability. This part is integral to maintaining stable fuel flow and reducing pulsations within the fuel system, contributing to overall engine performance 1.

Function and Operation

The BM76454 operates by stabilizing the fuel flow within the system. Positioned between the fuel pump and the fuel injectors, it mitigates the pulsations generated by the fuel pump. These pulsations, if left unchecked, can lead to inconsistent fuel delivery and increased wear on fuel system components. The damper accomplishes this by using a diaphragm that flexes to absorb the pressure variations, ensuring a smoother and more consistent fuel flow to the engine 2.

Purpose of the BM76454 Fuel Pump Damper

This Cummins part plays a specific role in the operation of a truck by contributing to the efficiency of the fuel system and enhancing engine performance. By stabilizing fuel flow, it helps maintain consistent fuel pressure, which is vital for the precise operation of fuel injectors. This consistency leads to more efficient combustion, improved fuel economy, and reduced emissions. Additionally, by reducing pulsations, the damper helps protect other fuel system components from premature wear, thereby extending their service life 3.

Key Features

The BM76454 is characterized by several key features that enhance its performance. Its design incorporates a durable diaphragm made from high-quality materials resistant to fuel and pressure variations. The damper is engineered to withstand the demanding conditions of heavy-duty truck applications. Additionally, it features precise manufacturing tolerances to ensure optimal performance and reliability. The compact design allows for easy integration into existing fuel systems without requiring significant modifications 4.

Benefits

The advantages provided by the BM76454 include improved fuel delivery, reduced wear on fuel system components, and enhanced engine reliability. By ensuring a stable and consistent fuel flow, the damper contributes to more efficient engine operation, leading to better fuel economy and reduced emissions. The reduction in pulsations also minimizes the stress on fuel lines, injectors, and other components, thereby extending their service life. Furthermore, the damper helps maintain engine reliability by ensuring consistent fuel pressure, which is critical for the proper functioning of modern fuel injection systems 1.

Installation Considerations

Proper installation of the BM76454 is crucial for its effective operation. It should be installed between the fuel pump and the fuel injectors, following the manufacturer’s guidelines. Before installation, it is important to ensure that the fuel system is clean and free of contaminants. Special tools may be required to properly seat the damper and ensure there are no leaks in the system. Following the recommended procedures will help ensure the damper functions as intended and provides the expected benefits 4.

Troubleshooting Common Issues

Typical problems associated with Fuel Pump Dampers can include leaks, diaphragm failure, and inadequate pulsation damping. If the damper is leaking, it should be inspected for damage and replaced if necessary. Diaphragm failure can often be identified by inconsistent fuel pressure or engine performance issues. In such cases, the damper should be replaced. If pulsations are still noticeable after installation, it may be necessary to re-evaluate the fuel system for other potential issues or ensure the damper is correctly installed 1.

Maintenance Tips

To ensure the longevity and optimal performance of the BM76454, routine maintenance practices should be followed. Regularly inspecting the damper for signs of wear or damage is important. Additionally, keeping the fuel system clean and free of contaminants will help prevent issues that could affect the damper’s performance. Following the manufacturer’s recommended service intervals for inspection and replacement will help maintain the efficiency and reliability of the fuel system 3.

Cummins Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes a wide range of power solutions, including engines, filtration, and emissions solutions. With a history spanning over a century, Cummins has established a strong reputation in the commercial truck industry for producing high-quality, reliable, and efficient products. The company’s extensive product range and commitment to innovation have made it a preferred choice for heavy-duty truck applications, ensuring that fleets operate with maximum efficiency and minimal downtime 4.

Cummins BM76454 Fuel Pump Damper Compatibility

The Cummins BM76454 Fuel Pump Damper is designed to ensure the smooth and efficient operation of the fuel system in various engine configurations. This part is engineered to fit seamlessly with several Cummins engine models, providing stability and reliability in fuel delivery.

L10 Mechanical

The BM76454 is compatible with the L10 Mechanical engine. This engine is known for its robust design and is often used in heavy-duty applications. The damper ensures that the fuel pump operates within optimal parameters, reducing wear and tear and enhancing the engine’s overall performance.

N14 Mechanical

Similarly, the N14 Mechanical engine benefits from the use of the BM76454 Fuel Pump Damper. This engine is another staple in the Cummins lineup, favored for its durability and power. The damper’s role in this engine is to maintain the integrity of the fuel system, ensuring consistent fuel flow and preventing potential issues that could arise from fuel pump vibrations.

V903

The V903 engine also integrates the BM76454 Fuel Pump Damper effectively. This engine is designed for high-performance applications and requires precise control over fuel delivery. The damper’s design helps in achieving this precision, contributing to the engine’s efficiency and longevity.

By ensuring compatibility with these engines, the Cummins BM76454 Fuel Pump Damper plays a vital role in maintaining the reliability and performance of the fuel system across various engine types 4.

Role of BM76454 Fuel Pump Damper in Engine Systems

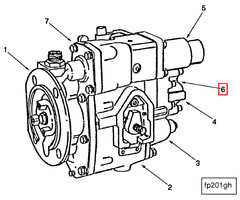

In the orchestration of engine systems, the BM76454 assumes a significant role by ensuring the stability and efficiency of fuel delivery. This component is integral to the Fuel Pump (F.P.) system, where it works in tandem with the Fuel Pump and Mounting Damper to mitigate pulsations and vibrations that arise from the fuel pump’s operation.

When the Fuel Pump draws fuel from the Fuel Base, it inherently generates pulsations due to the intermittent nature of its pumping action. These pulsations, if unchecked, can lead to inefficiencies in the Fuel Injection system, potentially affecting engine performance and longevity. The BM76454, as part of the F.P. and Mounting Damper assembly, absorbs these pulsations, providing a smoother flow of fuel to the Pump and subsequently to the Fuel Injection system.

The damper’s role extends beyond mere pulsation control; it contributes to the overall stability of the fuel system. By ensuring a consistent fuel flow, it aids in maintaining optimal pressure levels within the system, which is essential for the precise operation of the Fuel Injection components. This consistency is particularly important in modern engines where fuel injection systems demand a steady and reliable fuel supply to function at peak efficiency.

In summary, the BM76454 Fuel Pump Damper is a key component in the fuel delivery system, working silently yet effectively to enhance the performance and reliability of the engine’s fuel system. Its integration with the Fuel Pump, Fuel Base, and Fuel Injection system underscores its importance in the seamless operation of these interconnected components 1.

Conclusion

The BM76454 Fuel Pump Damper is a critical component in the fuel delivery system of heavy-duty trucks, ensuring stable and efficient fuel flow. Its role in mitigating pulsations and maintaining consistent fuel pressure contributes to improved engine performance, fuel economy, and emissions reduction. Proper installation, maintenance, and troubleshooting are essential to maximize the benefits of this Cummins part, ensuring the longevity and reliability of the fuel system 1234.

-

Dempsey, Paul. Troubleshooting and Repairing Diesel Engines, 5th Edition. McGraw-Hill, 2018.

↩ ↩ ↩ ↩ ↩ -

Goodnight, Nicholas, and Kirk Van Gelder. Automotive Braking Systems. Jones & Bartlett Learning, 2018.

↩ ↩ -

Schneider, Wolf-Henning. Pistons and Engine Testing. Springer Nature, 2016.

↩ ↩ ↩ -

Cummins Inc. QSC8.3 CM2880 C102, Service Manual (4388785).

↩ ↩ ↩ ↩ ↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.