This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

The Cummins 3201069 Fuel Drain Tube is a component designed for use in the fuel systems of heavy-duty trucks. Its primary role is to facilitate the draining of fuel from the system, which is necessary for routine maintenance or in emergency situations where fuel needs to be removed quickly. This part is integral to ensuring the fuel system operates efficiently and safely 1.

Purpose and Function

The Cummins 3201069 Fuel Drain Tube serves a specific function within the fuel system by providing a controlled means to drain fuel. This is particularly important during maintenance procedures where it is necessary to remove fuel for filter changes or system cleaning. Additionally, in emergency scenarios, the tube allows for rapid fuel removal, which can be crucial for safety. The tube is designed to ensure that fuel can be drained without causing spills or contamination, maintaining the integrity of the fuel system 2.

Key Features

The Cummins 3201069 Fuel Drain Tube is constructed with several key features that enhance its performance and durability. It is made from high-quality materials that resist corrosion and wear, ensuring longevity in demanding environments. The design includes a secure fitting mechanism that prevents leaks during operation. Additionally, the tube is engineered to withstand the pressures and temperatures typical in heavy-duty truck fuel systems, providing reliable performance over time 3.

Benefits

Using the Cummins 3201069 Fuel Drain Tube offers several benefits. It simplifies fuel system maintenance by providing a straightforward method for draining fuel, which can reduce downtime during service intervals. The tube enhances safety by allowing controlled fuel removal, minimizing the risk of spills and accidents. Furthermore, its robust construction contributes to the overall reliability of the fuel system, ensuring consistent performance in heavy-duty applications 4.

Installation and Usage

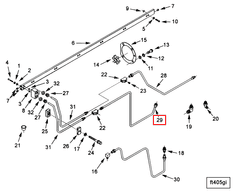

Proper installation of the Cummins 3201069 Fuel Drain Tube involves several steps to ensure safe and effective operation. Begin by locating the drain point in the fuel system and ensuring the truck is on a level surface. Use the appropriate tools to connect the tube securely to the drain fitting. When draining fuel, follow the manufacturer’s guidelines to avoid spills and ensure the work area is well-ventilated. After draining, securely reattach any caps or covers to prevent contaminants from entering the system.

Troubleshooting and Maintenance

Common issues with the Fuel Drain Tube may include leaks or blockages. To troubleshoot, inspect the connections for tightness and check for any signs of wear or damage. Regular maintenance involves ensuring the tube and fittings are free from debris and corrosion. Periodically testing the drain function can help identify potential problems before they become critical. Keeping the tube clean and well-lubricated (if applicable) will contribute to its longevity and performance.

Safety Considerations

When using the Cummins 3201069 Fuel Drain Tube, several safety considerations are important. Always handle fuel with care to avoid spills, which can be hazardous. Ensure that the work area is well-ventilated to dissipate any fuel vapors. Use appropriate personal protective equipment (PPE) such as gloves and safety glasses. Follow all manufacturer guidelines and local regulations regarding fuel handling and disposal.

Cummins Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a history spanning over a century, Cummins has established a reputation for quality and innovation in the automotive and heavy-duty truck industry. The company is committed to providing reliable and efficient solutions that meet the demanding needs of its customers, ensuring they can operate with confidence in various applications.

Compatibility

The Cummins Fuel Drain Tube, identified by the part number 3201069, is compatible with various Cummins engines, including the K19. This part is designed to facilitate the removal of water and sediment from the fuel tank, ensuring that the engine operates smoothly and efficiently.

Role in Engine Systems

The Cummins 3201069 Fuel Drain Tube is an essential component in the fuel system of an engine, facilitating the safe and efficient management of fuel flow. This tube is strategically integrated into the fuel system to ensure that any excess or contaminated fuel is effectively drained away from the primary fuel lines and components.

In conjunction with fuel tubing, the Fuel Drain Tube plays a significant role in maintaining the integrity of the fuel system. The fuel tubing transports fuel from the tank to the engine, while the Fuel Drain Tube provides a dedicated pathway for draining fuel that may have bypassed the filtration system or accumulated contaminants. This ensures that only clean fuel reaches the engine, thereby optimizing performance and longevity.

The integration of the Fuel Drain Tube with the fuel pump is also noteworthy. By ensuring that the fuel delivered to the pump is free from impurities, the tube helps maintain consistent fuel pressure and flow, which are vital for the pump’s efficient operation.

Additionally, the Fuel Drain Tube works in tandem with the fuel filter. While the filter captures larger particles, the drain tube addresses any fuel that may have circumvented the filtration process, providing an added layer of protection for downstream components such as the fuel injectors. This collaborative function helps prevent clogging and ensures precise fuel delivery to the combustion chambers.

Conclusion

The Cummins 3201069 Fuel Drain Tube is a vital component that enhances the reliability and efficiency of the engine’s fuel system by ensuring the removal of contaminants and maintaining the quality of fuel throughout the system.

-

Kershaw, John F. SAE International’s Dictionary for Automotive Engineers. SAE International, 2023.

↩ -

Eret, Angelina. Dynamic and Fatigue Assessment of Heavy-Duty Engine Valves. Springer Nature, 2024.

↩ -

Hilgers, Michael. The Drivers Cab. Springer Vieweg, 2022.

↩ -

Reif, Konrad Ed. Gasoline Engine Management Systems and Components. Springer Vieweg, 2015.

↩

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.