This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

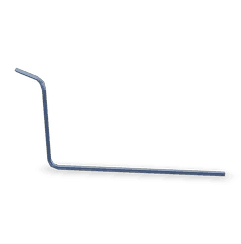

The Cummins 3254016 Fuel Drain Tube is a component designed for use in the fuel systems of heavy-duty trucks. Its primary role is to facilitate the draining of fuel from the system, which is necessary for routine maintenance or in emergency situations where fuel needs to be removed quickly and safely 1.

Purpose and Function

This Cummins part plays a role in the fuel system by providing a controlled method for draining fuel. This function is vital for several reasons. Firstly, it allows for the removal of contaminated fuel, which can occur due to water ingress or the presence of impurities. Secondly, it enables the system to be drained for maintenance purposes, such as filter changes or system inspections. Additionally, in emergency scenarios, the tube allows for rapid fuel removal, which can be crucial for safety 2.

Key Features

The Fuel Drain Tube is constructed from durable materials that are resistant to the corrosive effects of fuel. Its design includes features that enhance its performance and longevity, such as a secure fitting mechanism that ensures a tight seal when not in use, preventing fuel leaks. The tube is also designed for ease of use, with a straightforward operation that allows for quick and efficient fuel draining 3.

Benefits

Using the 3254016 offers several advantages. It simplifies fuel system maintenance by providing a dedicated pathway for fuel removal. This can lead to more efficient maintenance routines and reduced downtime for heavy-duty trucks. Additionally, the tube enhances safety during fuel draining procedures by providing a controlled outlet for fuel, minimizing the risk of spills or accidents. Furthermore, efficient fuel management facilitated by the tube can result in cost savings by reducing the amount of fuel wasted during maintenance operations.

Installation and Usage

Proper installation of this part involves securing it to the fuel system according to the manufacturer’s instructions. This may require specific tools or equipment, and it is important to follow safety precautions, such as ensuring the engine is off and the fuel system is depressurized before beginning installation. To drain fuel using the tube, one would typically open the valve or fitting associated with the tube, allowing fuel to flow out into a suitable container. It is important to follow recommended procedures to ensure safety and efficiency.

Troubleshooting and Maintenance

Common issues with the Fuel Drain Tube may include leaks or blockages. Troubleshooting these issues involves inspecting the tube and its connections for signs of wear or damage and ensuring that the fitting mechanism is secure. Regular maintenance of the tube, such as checking for corrosion or debris buildup, can help ensure optimal performance and longevity. It is also important to follow the manufacturer’s guidelines for maintenance to prevent issues from arising.

Safety Considerations

When working with the Cummins 3254016 Fuel Drain Tube, it is important to be aware of safety considerations. This includes proper handling of fuel, which is a flammable substance, and adherence to safety protocols when draining fuel from the system. Awareness of potential hazards, such as fuel spills or exposure to fuel vapors, is crucial to maintaining a safe working environment.

Cummins Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes a wide range of power solutions, including engines, filtration, and emissions solutions. With a history of innovation and a reputation for quality, Cummins is committed to manufacturing high-quality automotive components that meet the demanding requirements of heavy-duty applications. The company’s products are known for their reliability, performance, and durability, making them a preferred choice for professionals in the automotive and heavy-duty truck industries.

Role of Part 3254016 Fuel Drain Tube in Engine Systems

The 3254016 is an essential component within the Engine Block Module (EBM) that facilitates the safe and efficient management of fuel system operations. This component is integral to the plumbing network of the fuel system, ensuring that excess or contaminated fuel is effectively removed from the system.

Integration with Fuel System Components

-

Fuel Plumbing Network: The Fuel Drain Tube is a key element in the fuel plumbing network. It connects to various points within the system, allowing for the drainage of fuel that may have accumulated impurities or reached its operational limit. This helps maintain the integrity and performance of the fuel system.

-

Fuel Tubing: The tube interfaces with the fuel tubing, providing a dedicated pathway for draining fuel. This is particularly important in systems where fuel quality must be consistently high to ensure optimal engine performance.

-

Fuel Supply System: Within the fuel supply system, the drain tube plays a supportive role by offering a means to purge the system of any fuel that does not meet the required standards. This is vital for maintaining the efficiency and reliability of the fuel delivery process.

-

Supply Tube Mounting: The mounting of the supply tube is designed to accommodate the Fuel Drain Tube, ensuring that it is securely positioned and can effectively perform its function without interfering with other components.

-

Overall Fuel Management: The Fuel Drain Tube contributes to the overall fuel management strategy by providing a controlled method for fuel drainage. This is essential for routine maintenance procedures, such as fuel filter changes or system flushes, ensuring that the engine operates with clean and efficient fuel.

Conclusion

The Cummins 3254016 Fuel Drain Tube is a vital component in the fuel systems of heavy-duty trucks, offering a controlled and efficient method for draining fuel. Its durable construction, ease of use, and integration with the fuel system make it an essential part for maintaining the performance and safety of the engine. Regular maintenance and adherence to safety protocols are crucial for ensuring the longevity and effectiveness of this part.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.