This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

The Cummins 3600657 Fuel Drain Tube is a component designed for use in the fuel systems of heavy-duty trucks. Its primary role is to facilitate the safe and efficient drainage of fuel, which is necessary for routine maintenance or in emergency situations. This part is integral to ensuring the fuel system operates correctly and safely, contributing to the overall performance and reliability of the vehicle.

Purpose and Function

The Cummins 3600657 Fuel Drain Tube provides a controlled method for draining fuel. This function is vital for several reasons: it allows for the removal of contaminated fuel, aids in system cleaning, and can be used in emergency situations to quickly discharge fuel if necessary. The tube is designed to connect to the fuel tank and provide a pathway for fuel to be drained out, ensuring that this process is both safe and efficient 1.

Key Features

The Cummins 3600657 Fuel Drain Tube is constructed with several key features that enhance its performance and durability. It is made from high-quality materials that resist corrosion and wear, ensuring longevity in harsh operating environments. The design of the tube includes a secure fitting mechanism that ensures a tight seal, preventing fuel leaks during operation. Additionally, the tube is engineered to withstand the pressures and temperatures typical in heavy-duty truck fuel systems 2.

Benefits

Using the Cummins 3600657 Fuel Drain Tube offers several advantages. It simplifies the process of fuel system maintenance by providing a dedicated pathway for fuel drainage. This can reduce downtime during servicing and enhance safety by allowing for controlled fuel removal. The tube’s robust construction ensures reliability under various operating conditions, contributing to the overall efficiency and safety of the fuel system 3.

Installation and Usage

Proper installation of the Cummins 3600657 Fuel Drain Tube involves several steps to ensure it integrates seamlessly into the truck’s fuel system. First, the tube should be connected to the fuel tank using the provided fittings, ensuring a secure and leak-proof connection. It is important to follow the manufacturer’s guidelines for torque specifications and sealing procedures. Once installed, the tube should be tested for leaks before the vehicle is operated. Usage involves activating the drain valve to allow fuel to flow through the tube, which should be directed into a suitable container for disposal or recycling 4.

Maintenance and Troubleshooting

To ensure the longevity and optimal performance of the Cummins 3600657 Fuel Drain Tube, regular maintenance is recommended. This includes checking for signs of wear or corrosion, ensuring all connections are tight, and verifying that the drain valve operates correctly. Common issues may include leaks, which can often be resolved by tightening connections or replacing worn seals. If the tube shows significant signs of wear, it should be replaced to maintain system integrity.

Safety Considerations

When handling and maintaining the Cummins 3600657 Fuel Drain Tube, several safety guidelines should be observed. Always ensure that the vehicle is turned off and the fuel system is depressurized before beginning any work. Use appropriate personal protective equipment, such as gloves and safety glasses, to protect against fuel spills. During fuel drainage, ensure that the area is well-ventilated and free from ignition sources to prevent accidents. Adhere to local regulations and safety standards when disposing of drained fuel.

Cummins Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes a wide range of power solutions, including engines, filtration systems, and related technologies. Founded in 1919, Cummins has a long history of innovation and excellence in the automotive industry, particularly in the manufacturing of components for heavy-duty trucks. The company is known for its commitment to quality, reliability, and customer satisfaction, making it a trusted name in the industry.

Cummins Fuel Drain Tube (Part 3600657) Compatibility

The Cummins Fuel Drain Tube, identified by the part number 3600657, is a critical component in the fuel system of various Cummins engines. This part is designed to facilitate the removal of water and sediment from the fuel tank, ensuring that the engine operates smoothly and efficiently.

L10 Mechanical Engines

The Cummins L10 Mechanical engine is a robust and reliable power unit, often utilized in heavy-duty applications. The Fuel Drain Tube (3600657) fits seamlessly into the fuel system of the L10 Mechanical engine, providing a straightforward and effective method for draining water and contaminants from the fuel tank. This ensures that the engine’s performance is not compromised by impurities in the fuel.

Group Compatibility

The Fuel Drain Tube (3600657) is compatible with a range of Cummins engines beyond the L10 Mechanical. It is engineered to fit into the fuel systems of various engine models, ensuring that the same high-quality drainage solution can be applied across multiple platforms. This compatibility extends to other mechanical engines within the Cummins lineup, making it a versatile and essential component for maintaining fuel system integrity.

Role of Part 3600657 Fuel Drain Tube in Engine Systems

The Fuel Drain Tube (Part 3600657) is an essential component in the fuel system of an engine, designed to facilitate the safe and efficient removal of fuel from the system during maintenance or emergency situations. Its integration with various engine components ensures the system’s integrity and operational safety.

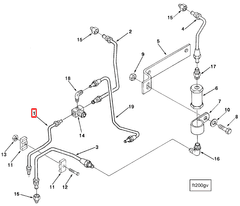

Integration with Fuel Plumbing

The Fuel Drain Tube is strategically positioned within the fuel plumbing system. It connects to the fuel tank and other critical fuel lines, allowing for the controlled release of fuel. This connection is vital for routine maintenance, such as filter changes or system inspections, where draining the fuel is necessary to prevent contamination and ensure the system’s cleanliness.

Interaction with the Fuel System

Within the broader fuel system, the Fuel Drain Tube works in conjunction with fuel pumps, filters, and injectors. When maintenance is required, the tube provides a direct pathway for fuel to be drained from the system, minimizing the risk of spills and ensuring that the fuel can be safely collected and disposed of. This is particularly important in high-pressure fuel systems where residual fuel can pose a safety hazard.

Role in Emergency Situations

In emergency scenarios, such as a fuel leak or system malfunction, the Fuel Drain Tube allows for rapid defueling. This capability is essential for mitigating risks associated with fuel system failures, enabling mechanics to quickly and safely remove fuel from the system to prevent further complications.

Contribution to System Reliability

By facilitating the efficient drainage of fuel, the Fuel Drain Tube contributes to the overall reliability and safety of the engine system. Regular use of the tube during maintenance helps to identify potential issues within the fuel lines and tank, allowing for early detection and resolution of problems that could otherwise lead to more significant failures.

Conclusion

The Cummins 3600657 Fuel Drain Tube is a vital component in the fuel systems of heavy-duty trucks, ensuring safe and efficient fuel drainage during maintenance and emergencies. Its robust construction, ease of installation, and compatibility with various Cummins engines make it an indispensable part for maintaining the integrity and reliability of the fuel system.

-

Kluczyk, B. (2008). How to Rebuild Any Automotive Engine. CarTech.

↩ -

Hiereth, H., Prenninger, P., & Drexl, K. W. (2010). Charging the Internal Combustion Engine. Springer.

↩ -

Awari, G. K., Kumbhar, V. S., & Tirpude, R. B. (2011). Automotive Systems Principles and Practice. CRC Press.

↩ -

Stone, R. (2012). Introduction to Internal Combustion Engines, Fourth Edition. Macmillan.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.