This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

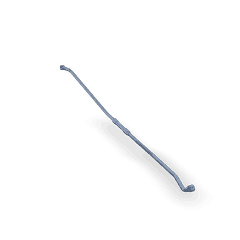

The Cummins 3972793 Fuel Drain Tube is a component designed for use in the fuel systems of heavy-duty trucks. Its primary role is to facilitate the draining of fuel, which is important for maintaining the integrity and efficiency of the fuel system. This tube ensures that fuel can be safely and effectively removed from the system during maintenance procedures or in the event of contamination 1.

Purpose and Function

The Cummins 3972793 Fuel Drain Tube serves a specific function within the fuel system by allowing for the controlled release of fuel. This is particularly important during maintenance operations where it may be necessary to drain fuel to replace filters, perform system checks, or address contamination. By providing a dedicated pathway for fuel drainage, the tube helps maintain the cleanliness and efficiency of the fuel system, ensuring optimal performance of the engine 2.

Key Features

The Cummins 3972793 Fuel Drain Tube is constructed from durable materials that are resistant to the corrosive effects of fuel. It features a robust design that includes secure connection points to ensure a leak-free seal within the fuel system. The tube is engineered to withstand the pressures and temperatures typical of heavy-duty truck applications. Additionally, it may include unique design elements such as reinforced sections or specialized fittings to enhance its functionality and reliability 3.

Benefits

Utilizing the Cummins 3972793 Fuel Drain Tube offers several advantages. It contributes to improved fuel system performance by allowing for efficient fuel drainage, which helps in maintaining system cleanliness. The tube’s design facilitates ease of maintenance, reducing the time and effort required for fuel system servicing. Its durable construction ensures long-term reliability, minimizing the need for frequent replacements and contributing to the overall longevity of the fuel system 4.

Installation Process

Installing the Cummins 3972793 Fuel Drain Tube involves several steps to ensure proper integration into the fuel system. Begin by identifying the correct location for the tube within the system. Use the appropriate tools to connect the tube to the fuel lines, ensuring all connections are secure and leak-free. It is important to follow the manufacturer’s guidelines for torque specifications when tightening fittings. After installation, perform a system check to verify that the tube is functioning correctly and that there are no leaks.

Maintenance and Troubleshooting

Regular maintenance of the Cummins 3972793 Fuel Drain Tube includes inspecting the tube and its connections for signs of wear or damage. It is important to ensure that the tube remains free of obstructions and that all connections are tight. Common issues that may arise include leaks at connection points or blockages within the tube. Troubleshooting steps involve checking for proper installation, ensuring all fittings are secure, and clearing any obstructions. If issues persist, it may be necessary to replace the tube.

Safety Considerations

When working with the Cummins 3972793 Fuel Drain Tube, it is important to follow safety guidelines to prevent accidents. Ensure that the fuel system is depressurized before beginning any work to avoid the risk of fuel spray. Use appropriate personal protective equipment, such as gloves and safety glasses, when handling fuel and components. Be aware of the flammable nature of fuel and take precautions to prevent sparks or open flames near the work area. Proper disposal of drained fuel is also important to comply with environmental regulations.

Cummins Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. Founded in 1919, Cummins has a long history of innovation and excellence in the automotive and heavy-duty truck industry. The company is known for its commitment to quality and reliability, providing solutions that meet the demanding requirements of various applications, including transportation, construction, and industrial uses.

Cummins Fuel Drain Tube 3972793 Compatibility

The Cummins Fuel Drain Tube part number 3972793 is designed to fit seamlessly with several engine models, ensuring efficient fuel management and maintenance. This component is crucial for the proper functioning of the fuel system, allowing for the removal of water and sediment that can accumulate in the fuel tank.

QSC8.3 CM850 (CM2850) Engines

The Cummins Fuel Drain Tube 3972793 is compatible with the QSC8.3 CM850 (CM2850) engines. This compatibility ensures that the part integrates smoothly with the fuel system of these engines, providing a reliable solution for fuel drainage.

Grouped Engine Compatibility

For the engines listed under the QSC8.3 CM850 (CM2850) category, the fuel drain tube is engineered to fit precisely, facilitating easy maintenance and ensuring the longevity of the engine’s fuel system. This part is essential for maintaining optimal engine performance by preventing contaminants from entering the fuel lines and injectors.

By ensuring that the fuel drain tube is correctly installed, users can avoid potential issues related to fuel contamination, which can lead to engine inefficiencies and increased maintenance costs. The compatibility of the part with these specific engine models underscores its importance in the overall maintenance and operational efficiency of the engines.

Role of Part 3972793 Fuel Drain Tube in Engine Systems

The part 3972793 Fuel Drain Tube is an integral component in the fuel system of an engine, facilitating the safe and efficient drainage of fuel. This tube is typically connected to the fuel tank and is designed to work in conjunction with various engine components to ensure optimal performance and safety.

Integration with Fuel System Components

- Fuel Tank: The Fuel Drain Tube is directly connected to the fuel tank. Its primary function is to allow for the controlled release of fuel, which is essential during maintenance procedures such as fuel filter replacement or when draining contaminated fuel.

- Fuel Lines: The tube interfaces with the fuel lines, ensuring that any drained fuel is safely directed away from the engine compartment. This prevents fuel spillage and reduces the risk of fire or environmental contamination.

- Fuel Filters: In systems where fuel filters are present, the Drain Tube plays a role in the filter change process. By draining the fuel before disconnecting the filter, it minimizes the mess and potential hazards associated with fuel spills.

- Plumbing System: The Drain Tube is part of the overall plumbing system within the engine. It ensures that fuel can be efficiently managed, whether for routine maintenance or emergency situations where fuel needs to be quickly drained.

- Safety Mechanisms: The tube is often incorporated into the engine’s safety systems. For instance, in the event of a fuel leak detected by the engine’s sensors, the Drain Tube can be activated to remove fuel from sensitive areas, thereby reducing the risk of ignition.

Operational Synergy

The Fuel Drain Tube operates in harmony with the engine’s fuel injection system and fuel pump. During regular operation, it remains closed, ensuring that fuel is delivered efficiently to the engine. However, when maintenance is required, the tube can be opened to allow for safe fuel drainage, ensuring that the fuel system remains clean and free from contaminants.

Conclusion

The Cummins 3972793 Fuel Drain Tube is a vital component that enhances the safety, efficiency, and maintainability of engine fuel systems. Its seamless integration with other components ensures that fuel management is both effective and secure.

-

Hilgers, Michael. Vocational Vehicles and Applications. Springer Nature, 2023.

↩ -

Xin, Qianfan. Diesel Engine System Design. Woodhead Publishing Limited, 2011.

↩ -

Brach, R. Matthew. SAE International’s Dictionary of Vehicle Accident Reconstruction and Automotive Safety. SAE International, 2023.

↩ -

Eret, Angelina. Dynamic and Fatigue Assessment of Heavy-Duty Engine Valves. Springer Nature, 2024.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.