This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

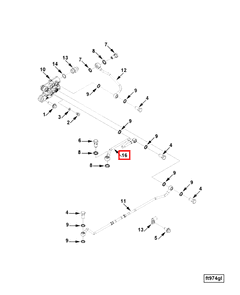

Understanding the Cummins 5254031 Fuel Drain Tube

Introduction

Cummins is a respected name in the automotive and heavy-duty truck industry, known for its robust and reliable engine components. Among these, the Cummins 5254031 Fuel Drain Tube is crucial for ensuring the smooth operation of commercial truck engines. This component is essential for maintaining fuel purity, which directly impacts engine performance and reliability 1.

Basic Concepts Related to Fuel Drain Tubes

A fuel drain tube is a vital part of the fuel system in commercial truck engines. Its primary function is to allow for the safe and efficient draining of fuel from the system. This is particularly important for maintenance purposes, such as when changing fuel filters or performing system cleanouts. The fuel drain tube integrates seamlessly into the fuel system, typically located near the fuel filter housing, facilitating easy access for draining operations 2.

Operationally, the fuel system of a commercial truck engine comprises several components, including the fuel tank, fuel lines, fuel filters, and the fuel injection system. The fuel drain tube plays a critical role in this system by ensuring that any contaminants or water that may have entered the fuel can be effectively removed. This helps in maintaining the purity of the fuel, which is essential for optimal combustion and engine performance 3.

Purpose of the Cummins 5254031 Fuel Drain Tube

The Cummins 5254031 Fuel Drain Tube is instrumental in enhancing the overall efficiency and reliability of the engine. Clean fuel is paramount for optimal combustion, and the fuel drain tube ensures that any impurities are regularly removed from the system. This not only improves engine performance but also extends the lifespan of other fuel system components 4.

In the context of truck operations, the fuel drain tube significantly impacts daily activities. A well-maintained fuel drain tube ensures that the truck operates smoothly, with minimal downtime. Conversely, a malfunctioning fuel drain tube can lead to contaminated fuel, resulting in poor engine performance, increased emissions, and potential damage to the fuel injection system.

Troubleshooting and Maintenance

Identifying signs of a failing fuel drain tube is crucial for maintaining engine health. Common symptoms include difficulty in draining fuel, leaks around the tube, or contaminated fuel. A clogged or damaged fuel drain tube can lead to more severe issues, such as fuel filter blockages and inefficient combustion.

Regular inspection and cleaning of the fuel drain tube are recommended best practices. Mechanics should incorporate these checks into their routine maintenance schedules. A typical maintenance routine might involve inspecting the tube for signs of wear or damage, ensuring that it is securely fitted, and cleaning any debris or contaminants from the area.

For troubleshooting, a step-by-step guide can be followed:

- Visual Inspection: Check for any visible signs of damage or wear.

- Functional Test: Attempt to drain fuel to ensure the tube is operating correctly.

- Cleaning: Use appropriate solvents to clean the tube and surrounding areas.

- Replacement: If damage is detected, replace the fuel drain tube with a compatible part.

Cummins: A Leader in Engine Technology

Cummins has a storied history in the automotive and heavy-duty truck industry, marked by numerous achievements and innovations. The company’s commitment to quality and innovation is evident in its fuel system components, including the 5254031 Fuel Drain Tube. Cummins continually invests in research and development to enhance the performance and reliability of its parts, ensuring that they meet the demanding requirements of commercial truck engines.

Expert Insights and Tips

Industry professionals emphasize the importance of regular maintenance and proper handling of fuel drain tubes. Tips from experienced engineers and mechanics include:

- Routine Checks: Incorporate fuel drain tube inspections into regular maintenance routines.

- Proper Cleaning: Use appropriate cleaning agents to avoid damaging the tube.

- Timely Replacements: Replace the fuel drain tube at the first sign of wear or damage to prevent more significant issues.

Case studies have shown that proper maintenance of fuel drain tubes can prevent major engine problems. For instance, regular cleaning and inspection have been proven to avoid fuel contamination, which can lead to costly repairs and downtime.

Conclusion

The Cummins 5254031 Fuel Drain Tube is a critical component in the fuel system of commercial truck engines. Its role in maintaining fuel purity and ensuring engine efficiency cannot be overstated. Regular maintenance and timely troubleshooting are essential practices for mechanics and engineers to adopt. By understanding the importance of this component and following best practices, professionals can ensure the reliable and efficient operation of commercial trucks.

-

Professor SG Tzafestas, Automotive Mechatronics: Operational and Practical Issues

↩ -

Gus Wright, CDX Automotive Fundamentals of Medium-Heavy Duty Diesel Engines, Jones & Bartlett Learning

↩ -

Michael Hilgers, Fuel Consumption and Consumption Optimization

↩ -

Cummins, Operation and Maintenance Manual, Bulletin Number 2883560

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.