This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

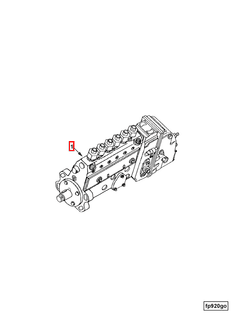

The Cummins Fuel Injection Pump Assembly, part number 3355291, is a critical component in the operation of commercial trucks. Cummins, a leader in the diesel engine industry, has designed this assembly to enhance the performance and efficiency of diesel engines used in heavy-duty applications. Understanding the role and functionality of this part is essential for maintaining and optimizing the performance of commercial trucks.

Basic Concepts of Fuel Injection Pump Assembly

Fuel injection pump assemblies are integral to the operation of diesel engines. They work by pressurizing fuel and delivering it to the engine’s combustion chambers at precise moments. This system differs from carburetor-based fuel delivery systems by providing more controlled and efficient fuel distribution. The precision of fuel delivery in diesel engines is crucial for achieving optimal combustion, which directly impacts engine performance and fuel efficiency 1.

Purpose and Function of the Cummins Fuel Injection Pump Assembly

The Cummins Fuel Injection Pump Assembly (part 3355291) plays a specific role in the operation of a truck by ensuring that fuel is delivered to the engine’s combustion chambers under high pressure and at the exact moment required for efficient combustion. This precise fuel delivery contributes to the engine’s performance by ensuring that the fuel burns completely, which enhances power output and fuel efficiency. Additionally, the assembly’s design helps in reducing emissions by promoting cleaner combustion 2.

Key Features of the Cummins Fuel Injection Pump Assembly

The Cummins Fuel Injection Pump Assembly (part 3355291) is characterized by several notable features. Its construction incorporates high-quality materials that ensure durability and reliability under the demanding conditions typical of commercial truck operations. The assembly is engineered with precision to meet the specific requirements of Cummins engines, ensuring compatibility and optimal performance. Its design also includes advanced features that enhance fuel delivery accuracy and efficiency 3.

Benefits of Using the Cummins Fuel Injection Pump Assembly

Utilizing the Cummins Fuel Injection Pump Assembly (part 3355291) offers several advantages. It contributes to improved fuel efficiency by ensuring that fuel is delivered to the engine in the most efficient manner possible. This results in better overall engine performance, as the precise fuel delivery supports optimal combustion. Additionally, the assembly’s robust construction and precision engineering make it reliable in demanding operating conditions, providing truck operators with peace of mind regarding their vehicle’s performance and durability.

Troubleshooting and Maintenance Tips

To ensure the optimal performance and longevity of the Cummins Fuel Injection Pump Assembly (part 3355291), it is important to be aware of common issues and follow recommended maintenance practices. Regular inspection and cleaning of the assembly can prevent buildup and ensure smooth operation. Additionally, monitoring the engine’s performance for signs of inefficient combustion, such as decreased power output or increased emissions, can help in early identification of potential issues with the fuel injection system. Following the manufacturer’s guidelines for maintenance and servicing is crucial for maintaining the assembly’s efficiency and reliability.

Cummins: A Brief Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes diesel and natural gas engines, as well as related technologies. With a history spanning over a century, Cummins has established a reputation for innovation, quality, and reliability in the diesel engine industry. The company’s commitment to advancing engine technology and providing comprehensive solutions for power needs underscores its position as a leader in the field. Cummins’ dedication to quality and innovation is evident in its product line, including the Cummins Fuel Injection Pump Assembly (part 3355291), which is designed to meet the high standards of performance and reliability expected in commercial truck applications.

Compatibility of Cummins Fuel Injection Pump Assembly 3355291

The Cummins Fuel Injection Pump Assembly (part 3355291) is a critical component for several engine models, ensuring precise fuel delivery and optimal engine performance. This part is designed to fit seamlessly with the following engines:

6C8.3 Engines

The Cummins 6C8.3 engine is a robust and reliable power unit often used in various industrial and commercial applications. The Cummins Fuel Injection Pump Assembly (part 3355291) is specifically engineered to integrate with the 6C8.3 engine, providing the necessary fuel metering and injection timing to maintain engine efficiency and power output.

Grouping of Compatible Engines

While the 6C8.3 is the primary engine model associated with the Cummins Fuel Injection Pump Assembly (part 3355291), it is also compatible with other similar Cummins engines. These engines share common design principles and operational requirements, ensuring that the fuel injection pump assembly can be used interchangeably across different models without compromising performance.

The compatibility of the Cummins Fuel Injection Pump Assembly (part 3355291) with these engines is due to the standardized design and engineering practices employed by Cummins, ensuring that the fuel injection pump assembly meets the specific needs of each engine model. This standardization allows for easier maintenance and repair, as technicians can use the same part across multiple engine types, reducing inventory needs and simplifying the repair process.

Role of Cummins Fuel Injection Pump Assembly 3355291 in Engine Systems

The Cummins Fuel Injection Pump Assembly (part 3355291) is integral to the efficient operation of modern engine systems. It works in concert with several key components to ensure optimal fuel delivery and engine performance.

Integration with the Fuel System

-

Fuel Tank: The journey of fuel begins in the tank, where it is stored under pressure. The Cummins Fuel Injection Pump Assembly draws fuel from here, ensuring a steady supply for combustion.

-

Fuel Filter: Before reaching the pump, fuel passes through a filter that removes impurities. This ensures that only clean fuel enters the injection pump, protecting it from damage and ensuring efficient operation.

-

Fuel Lines: These transport fuel from the tank to the injection pump. The design and material of these lines are important for maintaining fuel pressure and preventing leaks.

Operation within the Engine

-

Injectors: The Cummins Fuel Injection Pump Assembly meters and delivers fuel to the injectors. These injectors then spray atomized fuel into the combustion chamber at precise moments, optimizing air-fuel mixture for combustion.

-

Engine Control Unit (ECU): The ECU monitors various engine parameters and sends signals to the Cummins Fuel Injection Pump Assembly to adjust fuel delivery accordingly. This ensures that the engine operates efficiently under varying conditions.

-

Combustion Chamber: The atomized fuel mixes with air in the combustion chamber. The timing and quantity of fuel delivery, controlled by the injection pump, are vital for complete combustion and power generation.

Supporting Components

-

Sensors: Various sensors, such as the oxygen sensor and throttle position sensor, provide data to the ECU. This information helps the ECU make real-time adjustments to the Cummins Fuel Injection Pump Assembly’s operation.

-

Camshaft and Crankshaft: These components drive the Cummins Fuel Injection Pump Assembly mechanically in some engine designs. Their rotation ensures the pump operates in sync with the engine’s cycles.

-

Cooling System: Efficient operation of the Cummins Fuel Injection Pump Assembly also depends on the engine’s cooling system. Proper temperature management prevents overheating and ensures consistent performance.

Conclusion

In summary, the Cummins Fuel Injection Pump Assembly (part 3355291) is a pivotal component that interfaces with multiple systems within the engine, ensuring precise fuel delivery and contributing to overall engine efficiency and performance. Regular maintenance and adherence to manufacturer guidelines are essential for maximizing the longevity and reliability of this critical component.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.