This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

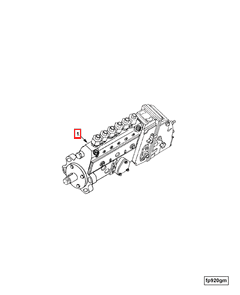

The Cummins 3355362 Fuel Injection Pump is a critical component in the operation of commercial trucks, ensuring that the diesel engine receives the precise amount of fuel needed for optimal performance, efficiency, and emissions control.

Basic Concepts of Fuel Injection Pumps

A fuel injection pump is responsible for delivering pressurized fuel to the engine’s combustion chambers. In diesel engines, this pump operates by drawing fuel from the tank, pressurizing it, and injecting it into the cylinders at the precise moment for combustion. The principles of fuel injection involve maintaining the correct fuel pressure and timing to ensure efficient engine operation. Fuel injection systems can be mechanical or electronic. Mechanical systems use physical components like cams and springs to control fuel delivery, while electronic systems utilize sensors and computer controls for more precise fuel management 1.

Purpose of the Cummins 3355362 Fuel Injection Pump

The Cummins 3355362 Fuel Injection Pump is designed to enhance the operation of trucks by ensuring accurate fuel delivery to the engine. It contributes to fuel efficiency by providing the right amount of fuel at the right time, which helps in achieving better mileage. Additionally, it plays a role in engine performance by ensuring consistent power output and smooth operation. The pump also aids in emissions control by promoting complete fuel combustion, which reduces the release of harmful pollutants 2.

Key Features

The Cummins 3355362 Fuel Injection Pump is characterized by its robust design and high-quality construction materials, which ensure durability and reliability. It incorporates advanced technological features such as precise fuel metering and efficient pressurization mechanisms. The pump’s design allows for easy integration into various truck fuel systems, making it a versatile component for different applications.

Benefits

Using the Cummins 3355362 Fuel Injection Pump offers several advantages. It provides improved fuel economy by ensuring optimal fuel delivery, which can lead to cost savings over time. The pump enhances engine performance by maintaining consistent fuel pressure and timing, resulting in smoother and more powerful operation. Additionally, it contributes to reduced emissions by promoting efficient fuel combustion, which helps in meeting environmental regulations 3.

Operational Mechanism

The Cummins 3355362 Fuel Injection Pump operates through a series of processes that include fuel pressurization, injection timing, and delivery to the engine cylinders. The pump draws fuel from the tank and pressurizes it using a plunger mechanism. It then injects the fuel into the cylinders at precise intervals, controlled by the pump’s cam and valve system. This ensures that the fuel is delivered at the optimal moment for combustion, maximizing engine efficiency and performance.

Installation and Integration

Proper installation and integration of the Cummins 3355362 Fuel Injection Pump into a truck’s fuel system are crucial for its effective operation. This involves mounting the pump in the designated location, connecting it to the fuel lines, and ensuring all electrical connections are secure. Any necessary adjustments or configurations should be made according to the manufacturer’s guidelines to ensure the pump operates within the specified parameters.

Troubleshooting and Maintenance

Common issues with the Cummins 3355362 Fuel Injection Pump can include fuel leaks, inconsistent fuel delivery, and pump failure. Troubleshooting these issues involves checking for proper fuel line connections, inspecting the pump for wear or damage, and ensuring the electrical connections are intact. Regular maintenance, such as cleaning the fuel filter, checking for leaks, and performing routine inspections, can help ensure the pump’s optimal performance and longevity.

Cummins Corporation

Cummins Inc. is a leading manufacturer in the commercial truck industry, known for its innovative products and commitment to quality. The company has a long history of providing reliable and high-performance engine components, including fuel injection pumps. Cummins is dedicated to advancing technology and meeting the needs of its customers through continuous innovation and superior product design.

Compatibility

The Cummins Fuel Injection Pump part number 3355362 is compatible with several engine models, including the 6B5.9. This part is designed to deliver fuel efficiently and precisely to the engine cylinders, ensuring optimal performance and reliability.

Compatible Engines

- 6B5.9: This engine model is known for its robust performance and reliability, often used in heavy-duty applications. The 3355362 fuel injection pump is engineered to work seamlessly with the 6B5.9 engine, providing the necessary fuel delivery to maintain engine efficiency and power output.

Engine Grouping

The Cummins 6B5.9 engine is part of a series of engines that share similar design principles and performance characteristics. The 3355362 fuel injection pump is specifically designed to fit within this engine group, ensuring compatibility and ease of integration. This allows for a streamlined maintenance and repair process, as the same fuel injection pump can be used across multiple engine models within this group.

Application Considerations

When installing the Cummins Fuel Injection Pump 3355362, it is essential to consider the specific requirements and conditions of the engine it will be paired with. Proper installation and calibration are crucial to ensure that the fuel injection pump operates correctly and efficiently, contributing to the overall performance and longevity of the engine.

Role in Engine Systems

The Cummins 3355362 Fuel Injection Pump, specifically designed as a Bosch injection pump, is integral to the operation of diesel engine systems. It works in concert with several key components to ensure efficient fuel delivery and combustion.

Interaction with the Common Rail System

In common rail systems, the Bosch injection pump pressurizes fuel and delivers it to a high-pressure accumulator, known as the common rail. From there, the fuel is distributed to individual injectors. The pump’s precise control over fuel pressure and timing is essential for optimal performance and emissions control.

Coordination with Fuel Injectors

The fuel injection pump directly influences the operation of fuel injectors. By providing a consistent and pressurized fuel supply, it allows injectors to atomize fuel finely, ensuring thorough mixing with air for complete combustion. This interaction is vital for achieving the desired power output and fuel efficiency.

Integration with the Engine Control Unit (ECU)

The Bosch injection pump often communicates with the ECU, which monitors various engine parameters such as load, speed, and temperature. The ECU adjusts the pump’s operation to maintain optimal fuel delivery under varying conditions, enhancing overall engine performance and reliability.

Relationship with the Fuel Filter

A clean fuel supply is imperative for the efficient operation of the injection pump. The fuel filter removes contaminants from the fuel before it reaches the pump, preventing wear and ensuring consistent performance. The pump’s ability to deliver precise fuel quantities relies on the quality of the fuel it receives.

Synergy with the Turbocharger

In turbocharged engines, the fuel injection pump must adapt to the increased air volume delivered by the turbocharger. It ensures that the fuel supply matches the higher airflow, maintaining the correct air-fuel ratio for efficient combustion and power delivery.

Collaboration with the Glow Plug System

In cold-start conditions, the glow plug system preheats the combustion chamber. The fuel injection pump must deliver fuel at the right pressure and timing to facilitate ignition in these conditions, ensuring smooth starts and reducing wear on engine components.

Impact on the Exhaust Gas Recirculation (EGR) System

The EGR system recirculates a portion of the exhaust gas to reduce nitrogen oxides (NOx) emissions. The fuel injection pump must adjust fuel delivery to compensate for the altered air-fuel mixture, ensuring that the engine operates efficiently while meeting emissions standards.

Conclusion

Understanding the role of the Cummins 3355362 Fuel Injection Pump within these engine systems allows engineers and mechanics to better diagnose issues, perform maintenance, and optimize engine performance. By ensuring proper installation, regular maintenance, and addressing compatibility considerations, users can maximize the efficiency and reliability of their diesel engines.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.