This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

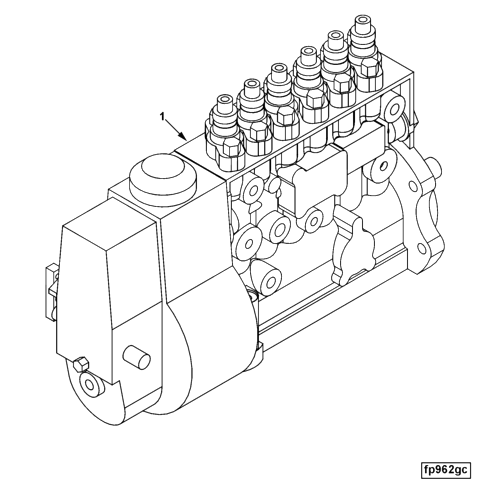

The Cummins 3415495 Fuel Injection Pump is a vital component in the operation of commercial trucks, particularly those equipped with Cummins diesel engines. This pump ensures the precise delivery of fuel to the engine’s combustion chambers, contributing to optimal engine performance, fuel efficiency, and emissions control 1.

Basic Concepts of Fuel Injection Pumps

A fuel injection pump delivers pressurized fuel to the engine’s combustion chambers. In diesel engines, this pump creates high-pressure fuel that is injected into the cylinders at precise moments to optimize combustion. The pump’s ability to control the timing and quantity of fuel delivered directly impacts engine performance and efficiency. Fuel injection systems can be mechanical or electronic, with electronic systems offering more precise management of the injection process 2.

Purpose of the Cummins 3415495 Fuel Injection Pump

The Cummins 3415495 Fuel Injection Pump enhances engine operation by ensuring accurate and timely fuel delivery. It provides the necessary fuel pressure and timing for efficient combustion, optimizes the fuel-air mixture for better mileage, and aids in emissions control by promoting complete combustion, thereby reducing harmful pollutants 3.

Key Features

The Cummins 3415495 Fuel Injection Pump is characterized by its robust design and construction, utilizing high-quality materials for durability and reliability. It incorporates advanced features such as precise fuel metering and high-pressure capabilities, essential for modern diesel engine performance. The pump’s design also includes provisions for easy maintenance and serviceability, making it a practical choice for commercial truck applications.

Benefits

The advantages of the Cummins 3415495 Fuel Injection Pump include improved fuel economy due to its efficient fuel delivery system, enhanced engine performance through optimal fuel-air mixture, reduced emissions through precise fuel delivery, and increased reliability designed to withstand the demanding conditions of commercial truck operation.

Installation and Integration

Proper installation of the Cummins 3415495 Fuel Injection Pump requires adherence to manufacturer guidelines, ensuring secure connections and correct alignment with the engine’s fuel system components. Consideration should be given to the pump’s compatibility with the engine model and any specific requirements for integration into the existing fuel system.

Troubleshooting Common Issues

Common problems associated with fuel injection pumps include leaks, erratic fuel delivery, and engine performance issues. Troubleshooting involves identifying symptoms such as engine misfires or difficulty starting, determining potential causes like clogged fuel filters or worn pump components, and applying recommended solutions such as cleaning or replacing faulty parts.

Maintenance Tips

Routine maintenance practices for the Cummins 3415495 Fuel Injection Pump include regular inspection for leaks or wear, cleaning to remove contaminants, and replacing worn components as necessary. Adhering to these maintenance procedures can help ensure the longevity and optimal performance of the pump.

Performance Enhancements

Potential upgrades or modifications to the Cummins 3415495 Fuel Injection Pump can further improve engine performance, power output, and fuel efficiency. This may involve the use of compatible aftermarket parts or tuning options designed to work with the pump. Careful consideration should be given to the compatibility and quality of any aftermarket components to ensure they meet the performance standards of the original equipment.

Cummins Company Overview

Cummins Inc. is a renowned manufacturer of diesel engines and powertrain technologies, known for innovation, quality, and customer satisfaction. The company has a history of developing advanced engine solutions that meet the demanding requirements of commercial and industrial applications. Cummins’ commitment to excellence is evident in its product line, which includes a wide range of diesel engines and components designed for durability, efficiency, and performance.

Cummins Fuel Injection Pump 3415495 Compatibility

The Cummins Fuel Injection Pump part number 3415495 is designed to work seamlessly with several engine models, including the 6C8.3, ensuring optimal performance and reliability.

Grouping of Engines

The 3415495 fuel injection pump is compatible with a broader range of engines, enhancing its versatility. These include the 6C8.3 engine model, specifically designed to work with the 3415495 pump, ensuring it meets stringent requirements for fuel delivery and engine performance.

Application Considerations

When using the Cummins Fuel Injection Pump 3415495, it is essential to ensure it is correctly matched with the engine specifications. This compatibility ensures the pump will function effectively, providing the necessary fuel pressure and timing for the engine to operate at peak efficiency.

Role of Part 3415495 Fuel Injection Pump in Engine Systems

The part 3415495 Fuel Injection Pump is integral to the efficient operation of engine systems, particularly in diesel engines where precise fuel delivery is essential for performance and emissions control. This component works in concert with several other engine components to ensure optimal fuel delivery and combustion.

Interaction with the Fuel System

- Fuel Tank and Fuel Lines: The fuel injection pump draws diesel from the fuel tank via the fuel lines. It is imperative that the fuel lines are free from obstructions and leaks to maintain consistent fuel pressure and flow.

- Fuel Filter: Before reaching the injection pump, the diesel passes through the fuel filter. This filter removes impurities that could damage the sensitive components within the pump or clog the injectors.

- Fuel Injectors: The fuel injection pump pressurizes the diesel and delivers it to the fuel injectors. These injectors then atomize the fuel into the combustion chamber at precise moments in the engine cycle, ensuring efficient combustion.

Coordination with Engine Components

- Engine Control Unit (ECU): Modern engines are equipped with an ECU that monitors various parameters such as engine speed, load, and temperature. The ECU sends signals to the fuel injection pump to adjust the fuel delivery accordingly, optimizing performance and fuel efficiency.

- Camshaft and Timing Mechanism: The fuel injection pump is often driven by the engine’s camshaft or a timing belt/chain. This mechanical linkage ensures that fuel injection is synchronized with the piston’s movement, enhancing combustion efficiency.

- Turbocharger (if equipped): In turbocharged engines, the fuel injection pump must deliver additional fuel to compensate for the increased air volume from the turbocharger. This ensures the air-fuel mixture remains within optimal combustion parameters.

- Exhaust Gas Recirculation (EGR) System: The EGR system recirculates a portion of the exhaust gas back into the intake to reduce nitrogen oxides (NOx) emissions. The fuel injection pump must adapt fuel delivery to accommodate the altered air-fuel ratio caused by the EGR system.

Impact on Engine Performance

The fuel injection pump’s role extends beyond mere fuel delivery; it influences several aspects of engine performance:

- Power Output: Precise fuel delivery ensures that the engine produces maximum power without unnecessary fuel consumption.

- Emissions Control: By delivering the correct amount of fuel at the right time, the pump helps minimize harmful emissions.

- Engine Longevity: Consistent and clean fuel delivery reduces the risk of engine wear and component failure.

Conclusion

The Cummins 3415495 Fuel Injection Pump is a pivotal component in the engine system, working in harmony with various other parts to ensure efficient, powerful, and clean engine operation. Its robust design, advanced features, and compatibility with a range of engine models make it a reliable choice for commercial truck applications.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.