This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

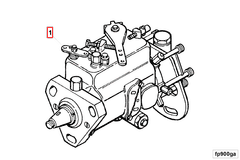

The Cummins 3908647 Fuel Injection Pump is a critical component in diesel engine systems, particularly in commercial trucks. It ensures precise and reliable fuel delivery to the engine cylinders, contributing to efficient engine operation. This part is part of Cummins Inc.’s extensive lineup of diesel engine components, renowned for their reliability and performance in demanding applications 1.

Basic Concepts of Fuel Injection Pumps

A fuel injection pump pressurizes diesel fuel and delivers it to the engine cylinders in a controlled manner. It uses mechanical or electronic systems to regulate the timing and amount of fuel injected, which is essential for combustion efficiency and engine performance 2. In diesel engines, the fuel injection pump ensures that fuel is delivered at the correct pressure and timing to optimize engine operation.

Operation of the Cummins 3908647 Fuel Injection Pump

The Cummins 3908647 operates through a series of mechanical and hydraulic processes. It includes a cam-driven plunger, a high-pressure fuel delivery system, and a control mechanism that regulates fuel flow. The pump uses engine-driven cams to move the plunger, pressurizing the fuel and delivering it to the injectors. This ensures that fuel is injected into the engine cylinders at the precise moment required for optimal combustion 3.

Purpose of the Cummins 3908647 Fuel Injection Pump

This Cummins part ensures efficient fuel delivery to the engine cylinders, enhancing engine performance and efficiency. It maintains consistent fuel pressure and timing, which is vital for the overall performance and reliability of the diesel engine 4.

Key Features

The Cummins 3908647 is characterized by precision engineering, durability, and compatibility with specific engine models. Its design ensures accurate fuel delivery, while its construction materials contribute to its longevity and reliability in demanding applications. The pump is engineered to meet the specific requirements of Cummins diesel engines, ensuring optimal performance and efficiency.

Benefits

This part offers several benefits, including improved fuel efficiency, enhanced engine performance, and reliable operation under various conditions. By ensuring precise fuel delivery, the pump contributes to more efficient combustion, which can lead to better fuel economy. Additionally, its robust design and precise engineering help maintain engine performance and reliability over time.

Troubleshooting Common Issues

Common issues associated with the Cummins 3908647 may include leaks, misfires, and irregular engine operation. Identifying these problems often involves checking for signs of fuel leakage, observing engine performance, and conducting diagnostic tests. Addressing these issues may require cleaning or replacing components, adjusting settings, or performing maintenance to ensure the pump operates correctly.

Maintenance Tips

To ensure optimal performance and longevity of the Cummins 3908647, regular maintenance is recommended. This includes conducting regular inspections for signs of wear or damage, cleaning components to remove any buildup, and replacing worn parts as necessary. Adhering to manufacturer guidelines for maintenance intervals and procedures can help maintain the pump’s efficiency and reliability.

Cummins Corporation

Cummins Inc. is a global power leader that designs, manufactures, and distributes a wide range of power solutions, including diesel engines, natural gas engines, and related technologies. With a history of innovation and quality, Cummins is committed to providing reliable and efficient power solutions for various applications, from commercial trucks to industrial equipment. The company’s product portfolio includes a range of components and systems designed to meet the demands of modern diesel engines.

Integration with the Fuel System

The Cummins 3908647 Fuel Injection Pump is integral to the efficient operation of modern engine systems. It works in conjunction with several key components to ensure optimal fuel delivery and combustion.

- Fuel Tank: The pump draws fuel from the tank, ensuring a consistent supply for the engine.

- Fuel Filter: Before reaching the injection pump, fuel passes through a filter to remove impurities, safeguarding the pump from damage.

- Fuel Lines: These transport the filtered fuel from the tank to the pump and subsequently to the injectors.

Coordination with Engine Components

- Engine Control Unit (ECU): The ECU monitors various engine parameters and sends signals to the injection pump to adjust fuel delivery based on real-time data.

- Injectors: The pump delivers pressurized fuel to the injectors, which then atomize the fuel into the combustion chamber.

- Combustion Chamber: Efficient fuel delivery by the pump ensures proper air-fuel mixture, leading to complete combustion and optimal engine performance.

- Turbocharger: In turbocharged engines, the pump must deliver fuel precisely to match the increased air intake, ensuring the engine operates within safe parameters.

Supporting Ancillary Systems

- Cooling System: Proper fuel delivery helps maintain engine temperature, reducing the load on the cooling system.

- Exhaust System: Efficient combustion results in cleaner exhaust emissions, supporting the function of catalytic converters and other emission control devices.

Conclusion

The Cummins 3908647 Fuel Injection Pump is a cornerstone in the fuel delivery process, interacting seamlessly with various engine and ancillary systems to ensure smooth and efficient operation. Its precise engineering, durability, and compatibility with specific engine models make it a vital component in the efficient operation of diesel engines.

-

Ribbens, W. B. (2003). Understanding Automotive Electronics. Elsevier Science.

↩ -

Kershaw, J. F. (2023). SAE International’s Dictionary for Automotive Engineers. SAE International.

↩ -

Watson, B. (2011). Mobile Equipment Hydraulics A Systems and Troubleshooting Approach. Cengage Learning.

↩ -

Xin, Q. (2011). Diesel Engine System Design. Woodhead Publishing.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.