This is an oversize product. Additional shipping fees may apply.

This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

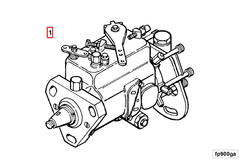

The Cummins 3908655 Fuel Injection Pump is a critical component in diesel engines, especially for commercial trucks. It ensures precise and controlled fuel delivery to the combustion chambers, contributing to efficient engine operation. This part is part of Cummins’ range of high-quality diesel engine components, recognized for their reliability and performance in demanding applications 1.

Basic Concepts of Fuel Injection Pumps

A fuel injection pump pressurizes diesel fuel and delivers it to the engine’s fuel injectors. It uses mechanical or electronic controls to regulate the amount of fuel injected into the engine’s cylinders. This precise control over fuel delivery is essential for efficient combustion in diesel engines, affecting both performance and emissions 2.

Role of the 3908655 Fuel Injection Pump in Truck Operation

The 3908655 Fuel Injection Pump ensures that fuel is delivered to the engine’s cylinders at the correct pressure and timing. This precise fuel delivery enhances the engine’s performance, including power output and fuel efficiency. By maintaining optimal fuel injection, the pump contributes to smoother engine operation and reduced emissions 3.

Key Features of the 3908655 Fuel Injection Pump

This Cummins part is characterized by several key features that enhance its performance and durability. Its design incorporates advanced materials and manufacturing techniques to ensure reliability under the demanding conditions of commercial truck operation. Technological advancements in the pump’s design contribute to its efficiency and longevity, making it a preferred choice for diesel engine applications 4.

Benefits of Using the 3908655 Fuel Injection Pump

Utilizing this part in a truck’s engine system offers several benefits. These include improved engine performance due to precise fuel delivery, enhanced fuel efficiency leading to cost savings, and increased reliability of the engine system. The pump’s design and construction also contribute to reduced maintenance requirements and longer service intervals 5.

Installation and Integration

When installing the 3908655 Fuel Injection Pump, it is important to follow manufacturer guidelines to ensure proper integration into the truck’s engine system. This includes verifying compatibility with the engine model and ensuring all connections are secure and leak-free. Proper installation is key to maximizing the pump’s performance and ensuring the engine operates efficiently 6.

Maintenance and Troubleshooting

Maintaining the 3908655 Fuel Injection Pump involves regular checks and cleaning to ensure its continued efficient operation. This includes inspecting for leaks, ensuring all connections are tight, and cleaning or replacing filters as necessary. Troubleshooting common issues may involve checking for proper fuel pressure, inspecting the pump for wear or damage, and ensuring the engine’s fuel system is free of contaminants 7.

Performance and Efficiency

The 3908655 Fuel Injection Pump contributes to the overall performance and efficiency of the truck’s engine by ensuring precise fuel delivery. This leads to more efficient combustion, which can result in increased power output and improved fuel economy. The pump’s role in maintaining optimal fuel injection timing and pressure is crucial for achieving these performance benefits 8.

Common Issues and Solutions

Common issues with the 3908655 Fuel Injection Pump may include leaks, reduced fuel pressure, or engine performance issues. Solutions or maintenance actions can range from tightening connections and replacing worn components to more comprehensive repairs or replacements, depending on the issue’s severity. Regular maintenance and prompt attention to any signs of trouble can help prevent more serious problems 9.

About Cummins

Cummins Inc. is a global power leader that designs, manufactures, and distributes a wide range of power solutions, including diesel and natural gas engines, as well as related technologies. With a history of innovation and quality, Cummins has established itself as a trusted name in the manufacturing of diesel engines and components, serving a variety of industries with reliable and efficient power solutions 10.

Integration with the Fuel System

-

Fuel Tank: The journey of fuel begins in the fuel tank, where it is stored until needed. The fuel injection pump draws fuel from the tank via the fuel lines.

-

Fuel Filter: Before reaching the injection pump, fuel passes through the fuel filter. This component removes impurities and contaminants, ensuring that only clean fuel enters the pump.

-

Fuel Lines: These transport fuel from the tank to the injection pump and from the pump to the injectors. The integrity of these lines is essential for maintaining consistent fuel pressure and flow.

Operation within the Engine

-

Fuel Injectors: The fuel injection pump pressurizes the fuel and delivers it to the fuel injectors. These injectors atomize the fuel into a fine mist, allowing for better combustion efficiency.

-

Engine Control Unit (ECU): The ECU monitors various engine parameters and sends signals to the fuel injection pump to adjust fuel delivery based on real-time data. This ensures optimal fuel-air mixture for varying engine loads and speeds.

-

Combustion Chambers: The atomized fuel is injected into the combustion chambers, where it mixes with air and ignites, driving the pistons and generating power.

Supporting Components

-

Camshaft and Crankshaft: The precise timing of fuel injection is often synchronized with the movement of the camshaft and crankshaft. This ensures that fuel is delivered at the optimal moment in the engine cycle.

-

Turbocharger (if present): In turbocharged engines, the fuel injection pump must deliver fuel in quantities that match the increased air intake provided by the turbocharger, ensuring balanced combustion.

-

Exhaust Gas Recirculation (EGR) System: The fuel injection pump also plays a role in the EGR system by providing the necessary fuel adjustments to accommodate recirculated exhaust gases, which help reduce emissions.

By understanding how the 3908655 Fuel Injection Pump interacts with these components, engineers and mechanics can better diagnose issues, perform maintenance, and optimize engine performance.

Conclusion

The Cummins 3908655 Fuel Injection Pump is a vital component in diesel engine systems, ensuring precise fuel delivery and contributing to engine performance, efficiency, and emissions control. Its integration with the fuel system and operation within the engine, along with its interaction with supporting components, highlights its importance in modern engine technology.

-

Hillier, Alma. Fundamentals of Motor Vehicle Technology Book 1 6th Edition. Oxford University Press, 2014.

↩ -

Huzij, Robert, et al. Modern Diesel Technology: Heavy Equipment Systems. Cengage Learning, 2019.

↩ -

Dixon, John. Modern Diesel Technology: Heating, Ventilation, Air Conditioning, Refrigeration, 2nd Edition. Cengage Learning, 2014.

↩ -

Naunheimer, Harald, et al. Automotive Transmissions Fundamentals Selection Design and Application. Springer Vieweg, 2011.

↩ -

Hillier, Alma. Fundamentals of Motor Vehicle Technology Book 1 6th Edition. Oxford University Press, 2014.

↩ -

Huzij, Robert, et al. Modern Diesel Technology: Heavy Equipment Systems. Cengage Learning, 2019.

↩ -

Dixon, John. Modern Diesel Technology: Heating, Ventilation, Air Conditioning, Refrigeration, 2nd Edition. Cengage Learning, 2014.

↩ -

Naunheimer, Harald, et al. Automotive Transmissions Fundamentals Selection Design and Application. Springer Vieweg, 2011.

↩ -

Huzij, Robert, et al. Modern Diesel Technology: Heavy Equipment Systems. Cengage Learning, 2019.

↩ -

Dixon, John. Modern Diesel Technology: Heating, Ventilation, Air Conditioning, Refrigeration, 2nd Edition. Cengage Learning, 2014.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.