This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

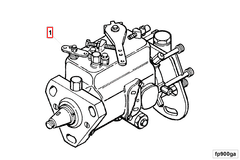

The Cummins 3908974 Fuel Injection Pump is a vital component in the operation of commercial trucks, particularly those equipped with Cummins diesel engines. This part plays a significant role in the fuel delivery system, ensuring that the engine receives the precise amount of fuel needed for optimal performance. Its efficient operation contributes to the overall reliability and efficiency of the truck 4.

Basic Concepts of Fuel Injection Pumps

A fuel injection pump is a device that delivers fuel to the engine’s combustion chambers. It operates by pressurizing fuel and injecting it into the engine at precise moments to maximize combustion efficiency. In diesel engines, the fuel injection pump is crucial for achieving the high-pressure injection required for proper fuel atomization and combustion. There are two primary types of fuel injection systems: mechanical and electronic. Mechanical systems rely on physical components and cam-driven mechanisms to control fuel delivery, while electronic systems use sensors and computer controls to manage injection timing and quantity 1.

Purpose of the Cummins 3908974 Fuel Injection Pump

The Cummins 3908974 Fuel Injection Pump is designed to deliver fuel to the engine in a controlled and precise manner. It contributes to engine performance by ensuring that the fuel is injected at the correct pressure and timing. This precision helps to optimize fuel efficiency, enhance engine power, and reduce emissions. The pump’s role in the fuel delivery system is fundamental to the overall operation and efficiency of the truck 4.

Key Features

The Cummins 3908974 Fuel Injection Pump is characterized by several key features that enhance its performance and reliability. Its design incorporates high-quality materials that withstand the rigors of heavy-duty use. The pump may include advanced technological features such as precision machining and durable construction, which contribute to its efficiency and longevity. These features ensure that the pump can operate under various conditions without compromising performance 2.

Benefits

Using the Cummins 3908974 Fuel Injection Pump offers several benefits. One of the primary advantages is improved fuel economy, as the pump’s precise fuel delivery helps to optimize combustion. This efficiency translates to cost savings for fleet operators. Additionally, the pump contributes to enhanced engine performance, providing consistent power output and reliability. Reduced emissions are another benefit, as precise fuel injection helps to minimize pollutants. The pump’s durable construction also ensures increased longevity, reducing the need for frequent replacements 4.

Installation and Integration

Proper installation and integration of the Cummins 3908974 Fuel Injection Pump are crucial for ensuring optimal performance. It is important to follow manufacturer guidelines to ensure compatibility with the truck’s engine system. Professional installation is recommended to avoid potential issues and ensure that the pump is correctly aligned and secured. Compatibility with various engine models should be verified to ensure seamless integration 3.

Troubleshooting and Maintenance

Common issues with the Cummins 3908974 Fuel Injection Pump may include leaks, inconsistent fuel delivery, or pump failure. Troubleshooting steps may involve checking for proper installation, inspecting for wear or damage, and ensuring that all connections are secure. Regular maintenance, such as cleaning and inspecting the pump, is vital for ensuring its longevity and optimal performance. Periodic servicing by a professional can help identify potential issues before they become critical 4.

Performance Optimization

To optimize the performance of the Cummins 3908974 Fuel Injection Pump, several strategies can be employed. Tuning the injection timing and pressure can enhance efficiency and power output. Upgrades such as high-performance injectors or improved fuel filters can further optimize the system. Adhering to best practices for maintenance and operation ensures that the pump operates at peak efficiency 4.

Cummins Corporation

Cummins Inc. is a renowned manufacturer in the automotive industry, known for its commitment to innovation, quality, and customer satisfaction. The company offers a wide range of products, including engines, filtration systems, and power generation equipment. Cummins’ reputation is built on its dedication to producing reliable and high-performing components, making it a trusted name in the industry 4.

Role of Part 3908974 Fuel Injection Pump in Engine Systems

This Cummins part is an integral component in the fuel delivery system of an engine. It works in conjunction with several other components to ensure efficient and precise fuel delivery, which is essential for optimal engine performance 4.

Interaction with the Fuel Pump

The fuel pump is responsible for drawing fuel from the tank and delivering it to the fuel injection pump. The fuel injection pump, part 3908974, then takes this fuel and pressurizes it to the levels required for injection into the engine’s combustion chambers. This pressurized fuel is then distributed to the individual injectors, which atomize the fuel into a fine mist for combustion 4.

Coordination with Fuel Injectors

Fuel injectors are the final point in the fuel delivery system where pressurized fuel is released into the engine’s cylinders. The fuel injection pump ensures that the fuel injectors receive a consistent and precise amount of pressurized fuel. This precision is vital for maintaining the correct air-fuel ratio, which directly impacts engine efficiency, power output, and emissions 4.

Integration with Engine Control Unit (ECU)

The Engine Control Unit (ECU) plays a significant role in regulating the fuel injection process. It monitors various engine parameters such as engine speed, load, and temperature. Based on this data, the ECU sends signals to the fuel injection pump to adjust the fuel delivery rate accordingly. This dynamic adjustment ensures that the engine operates efficiently under varying conditions 4.

Synergy with Sensors

Various sensors, such as the Mass Air Flow (MAF) sensor and Oxygen (O2) sensor, provide real-time data to the ECU about the air-fuel mixture and exhaust emissions. The fuel injection pump responds to these inputs by modulating the fuel delivery, thus maintaining optimal combustion conditions 4.

Contribution to Overall Engine Performance

By ensuring precise and consistent fuel delivery, the fuel injection pump significantly contributes to the engine’s overall performance. It helps in achieving better fuel economy, reduced emissions, and enhanced power output. The pump’s ability to maintain high pressure and deliver fuel at the right moment is essential for the engine’s smooth operation and longevity 4.

Conclusion

The Cummins 3908974 Fuel Injection Pump is a critical component in the fuel delivery system of commercial trucks. Its precise and efficient operation ensures optimal engine performance, improved fuel economy, and reduced emissions. Proper installation, regular maintenance, and performance optimization strategies are essential for maximizing the benefits of this part. Cummins Inc.’s commitment to quality and innovation ensures that this fuel injection pump remains a reliable and high-performing component in the industry 4.

-

Mohamed ElSayed PE, Fundamentals of Integrated Vehicle Realization (SAE International, 2017).

↩ -

Matthew Harrison, Controlling Noise and Vibration in Road Vehicles (SAE International, 2004).

↩ -

Cummins Inc., Operation and Maintenance Manual for B4.5 CM2350 B159C, Bulletin Number 5579839.

↩ -

Owen C Duffy and Gus Wright, Fundamentals of Medium-Heavy Duty Commercial Vehicle Systems (Jones Bartlett Learning, 2016).

↩ ↩ ↩ ↩ ↩ ↩ ↩ ↩ ↩ ↩ ↩ ↩ ↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.