This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

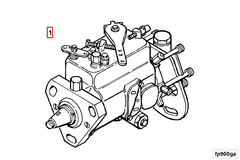

The Cummins 3910044 Fuel Injection Pump is a critical component in the operation of commercial trucks, especially those equipped with Cummins diesel engines. This part is engineered to deliver fuel to the engine at precise timing and pressure, ensuring optimal performance and efficiency. Its role in the fuel delivery system is significant, contributing to the overall reliability and effectiveness of the truck’s engine.

Basic Concepts of Fuel Injection Pumps

A fuel injection pump is a device that delivers fuel to the engine’s combustion chambers at the correct pressure and timing. In diesel engines, this process is essential for efficient combustion and power generation. Fuel injection pumps can be mechanical or electronic. Mechanical pumps use physical components and cam-driven mechanisms to control fuel delivery, while electronic pumps utilize sensors and electronic controls for more precise fuel management. The transition from mechanical to electronic systems has allowed for greater accuracy in fuel delivery, leading to improvements in engine performance and emissions control 1.

Purpose of the Cummins 3910044 Fuel Injection Pump

The Cummins 3910044 Fuel Injection Pump ensures that fuel is delivered to the engine at the precise timing and pressure required for efficient combustion. This part is responsible for atomizing the fuel into fine particles, which mix with air in the combustion chamber to produce power. The accurate delivery of fuel is essential for maintaining engine performance, fuel efficiency, and emissions standards 2.

Key Features

The Cummins 3910044 Fuel Injection Pump is characterized by its robust design and the use of high-quality materials, which contribute to its durability and reliability. This part incorporates advanced technological features such as precision engineering and electronic controls, which enhance its performance. The design of the pump allows for efficient fuel delivery, while the materials used ensure it can withstand the demanding conditions of commercial truck operation 3.

Benefits

The Cummins 3910044 Fuel Injection Pump offers several benefits, including improved fuel efficiency, enhanced engine performance, and reduced emissions. By delivering fuel at the optimal pressure and timing, this part helps to maximize the engine’s efficiency and power output. Additionally, the precise control of fuel delivery contributes to lower emissions, making it an environmentally friendly choice for commercial truck applications.

Installation and Integration

Installing the Cummins 3910044 Fuel Injection Pump requires careful consideration of compatibility with the truck’s engine model. Proper installation is crucial to ensure the pump functions correctly and integrates seamlessly with the engine’s fuel system. Following manufacturer guidelines and using the appropriate tools and techniques will help to achieve a successful installation, ensuring the pump operates efficiently and reliably.

Maintenance and Troubleshooting

Regular maintenance of the Cummins 3910044 Fuel Injection Pump is important to ensure its continued performance and longevity. This includes inspecting the pump for signs of wear or damage, checking fuel lines and connections for leaks, and ensuring that all components are clean and free from debris. Common issues to watch for include irregular engine performance, changes in fuel efficiency, and unusual noises from the pump. Troubleshooting these issues may involve checking the pump’s electrical connections, inspecting the fuel filter, and ensuring that the pump is receiving the correct voltage.

Performance Enhancements

The Cummins 3910044 Fuel Injection Pump contributes to overall truck performance by providing precise fuel delivery, which enhances power output and torque. The pump’s ability to deliver fuel at the optimal pressure and timing ensures that the engine operates efficiently, leading to improved fuel economy. These performance enhancements are particularly beneficial for commercial trucks, where efficiency and reliability are paramount.

Technological Advancements

The Cummins 3910044 Fuel Injection Pump incorporates several technological advancements that improve its functionality. Precision engineering ensures that the pump delivers fuel with accuracy, while electronic controls allow for fine-tuning of fuel delivery based on engine conditions. These advancements contribute to the pump’s reliability, efficiency, and performance, making it a valuable component in modern diesel engines.

Environmental Impact

The use of the Cummins 3910044 Fuel Injection Pump has a positive environmental impact due to its role in reducing emissions and improving fuel efficiency. By delivering fuel more precisely, the pump helps to ensure complete combustion, which reduces the emission of harmful pollutants. Additionally, the improved fuel efficiency contributes to lower fuel consumption, further reducing the environmental footprint of commercial trucks.

Cummins Overview

Cummins Inc. is a leading manufacturer of diesel engines and related technologies, with a reputation for quality and innovation in the industry. Founded in 1919, Cummins has a long history of developing reliable and efficient engine components, including fuel injection pumps. The company’s commitment to technological advancement and environmental responsibility is reflected in its products, such as the Cummins 3910044 Fuel Injection Pump.

Role of Part 3910044 Fuel Injection Pump in Engine Systems

The Part 3910044 Fuel Injection Pump is integral to the efficient operation of engine systems by ensuring precise fuel delivery. This part works in conjunction with several key components to optimize engine performance.

Integration with the Fuel System

-

Fuel Tank: The pump draws fuel from the tank, where it is stored under pressure. This ensures a consistent supply of fuel to the engine, regardless of the vehicle’s orientation or fuel level.

-

Fuel Filter: Before reaching the injection pump, fuel passes through a filter that removes impurities. This protects the pump from damage and ensures clean fuel is delivered to the engine.

-

Fuel Lines: These transport fuel from the tank to the pump and from the pump to the injectors. The pump maintains the necessary pressure within these lines to facilitate efficient fuel delivery.

Interaction with Engine Components

-

Injectors: The pump delivers pressurized fuel to the injectors, which spray atomized fuel into the combustion chamber. This precise delivery is essential for achieving the correct air-fuel mixture, which is vital for combustion efficiency and power output.

-

Engine Control Unit (ECU): The ECU monitors various engine parameters and adjusts the fuel injection timing and quantity. The pump must respond accurately to these signals to maintain optimal engine performance.

-

Camshaft and Crankshaft Sensors: These sensors provide data on engine speed and position, allowing the ECU to time the fuel injection precisely. The pump’s ability to deliver fuel at the exact moment required is dependent on this timing information.

Impact on Engine Performance

-

Combustion Efficiency: By ensuring that fuel is delivered at the right pressure and timing, the pump enhances combustion efficiency, leading to better fuel economy and reduced emissions.

-

Power Output: Consistent and precise fuel delivery allows the engine to operate at its peak power output, improving overall vehicle performance.

-

Engine Longevity: Proper fuel delivery reduces the risk of engine knocking and other performance issues, contributing to the longevity of the engine components.

Conclusion

The Cummins 3910044 Fuel Injection Pump is a vital component in the operation of commercial trucks, ensuring precise fuel delivery for optimal engine performance, efficiency, and reduced emissions. Its robust design, advanced technological features, and integration with the engine’s fuel system make it a reliable and efficient choice for modern diesel engines.

-

Bennett, S. (2012). Modern Diesel Technology: Light Duty Diesels. Cengage Learning.

↩ -

Gilles, T. (2020). Automotive Service: Inspection, Maintenance, Repair: 2nd Edition. Cengage Learning.

↩ -

Zhan, Q., Eben, S., & Deng, L. K. (2018). Automotive Heating Ventilation and Air Conditioning. Jones Bartlett Learning.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.