This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

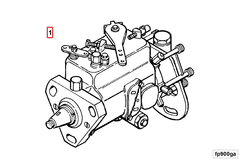

The Cummins 3916530 Fuel Injection Pump is a critical component for commercial trucks, ensuring precise fuel delivery to engine cylinders. This part is essential for the efficient and reliable performance of diesel engines in heavy-duty trucks 1.

Basic Concepts of Fuel Injection Pumps

Fuel injection pumps deliver fuel to engine combustion chambers by pressurizing it and injecting it at specific timings to optimize combustion. Diesel engines rely on these pumps to control fuel delivery, affecting performance and efficiency. There are two main types of fuel injection systems: mechanical and electronic. Mechanical systems use physical components and cam-driven mechanisms, while electronic systems employ sensors and electronic controls for precise fuel management 2.

Purpose of the Cummins 3916530 Fuel Injection Pump

The Cummins 3916530 is designed to deliver fuel with precision in timing and pressure, ensuring optimal combustion. This contributes to maintaining the engine’s power output and fuel economy 3.

Key Features

This Cummins part features high-quality materials for durability and reliability. It may include precision engineering and electronic controls, enhancing performance and efficiency. These features ensure accurate and consistent fuel delivery 4.

Benefits of Using the Cummins 3916530 Fuel Injection Pump

Using this part improves fuel efficiency by delivering fuel in optimal quantity and at the precise moment. This enhances engine performance and power. The pump’s reliable design also contributes to the engine’s durability and longevity.

Installation and Integration

Installing the Cummins 3916530 requires attention to specific requirements for proper integration into truck models. The process involves aligning the pump with the engine’s fuel system components and ensuring secure connections. Following manufacturer guidelines is crucial for optimal performance and compatibility.

Maintenance and Troubleshooting

Regular maintenance is necessary to ensure the Cummins 3916530 operates at its best. This includes inspecting for wear or damage, checking fuel lines for leaks, and ensuring tight connections. Common issues may involve irregular fuel delivery or engine performance problems. Troubleshooting tips may include checking for clogged fuel filters or malfunctioning sensors.

Performance and Efficiency

The Cummins 3916530 plays a significant role in the truck’s performance and efficiency. By delivering fuel with precision, it contributes to better fuel economy and increased power output. The pump’s design and technological features aim to optimize the engine’s combustion process, directly impacting operational efficiency.

Technological Advancements

This part incorporates technological innovations such as precision engineering for accurate fuel delivery and electronic controls for enhanced management of the injection process. These advancements contribute to the pump’s reliability, efficiency, and overall performance in diesel engines.

Cummins Overview

Cummins Inc. is renowned in the automotive industry for its diesel engines and components. The company’s commitment to innovation and quality is evident in its products, including the Cummins 3916530 Fuel Injection Pump.

Role of Part 3916530 Fuel Injection Pump in Engine Systems

The 3916530 Fuel Injection Pump is integral to the efficient operation of engine systems by ensuring precise fuel delivery to the combustion chambers. This component works in concert with several other engine components to optimize performance and fuel economy.

Interaction with the Base Fuel Pump

The base fuel pump draws fuel from the tank and delivers it to the 3916530 under low pressure. Once the fuel reaches this part, it is pressurized to a much higher level. This high-pressure fuel is then distributed to the injectors, which atomize the fuel into the combustion chambers at the precise moment required for optimal combustion.

Coordination with Fuel Injectors

Fuel injectors rely on the consistent, high-pressure fuel supply provided by the 3916530. The pump ensures that each injector receives the exact amount of fuel needed at the right time, enhancing combustion efficiency and reducing emissions. The precise timing and pressure regulation by the injection pump are essential for the injectors to perform their function effectively.

Integration with the Engine Control Unit (ECU)

The Engine Control Unit (ECU) monitors various engine parameters and adjusts the fuel delivery accordingly. The 3916530 receives signals from the ECU to modulate fuel pressure and delivery rate. This dynamic interaction allows the engine to adapt to changing conditions, such as load, speed, and environmental factors, ensuring optimal performance across a wide range of operating conditions.

Synergy with the Common Rail System

In engines equipped with a common rail fuel system, the 3916530 plays a pivotal role in maintaining the high-pressure fuel reservoir. The pump pressurizes the fuel, which is then stored in the common rail. From there, the fuel is distributed to each injector as needed. This system allows for more precise control over fuel delivery, enhancing both performance and fuel efficiency.

Contribution to Turbocharger Efficiency

In turbocharged engines, the 3916530’s ability to deliver high-pressure fuel is particularly important. The increased air density from the turbocharger requires a corresponding increase in fuel delivery to maintain the correct air-fuel ratio. The injection pump ensures that the fuel system can meet these demands, supporting the turbocharger’s role in enhancing engine power and efficiency.

Enhancement of Aftertreatment Systems

Modern engines are equipped with aftertreatment systems to reduce emissions. The 3916530 contributes to the effectiveness of these systems by ensuring precise fuel delivery, which helps in maintaining optimal combustion conditions. This reduces the formation of harmful emissions and supports the function of components like Diesel Particulate Filters (DPF) and Selective Catalytic Reduction (SCR) systems.

Conclusion

The 3916530 Fuel Injection Pump is a key component that enhances the functionality and efficiency of various engine systems through its precise control of fuel delivery. Its integration with other engine components ensures optimal performance, fuel economy, and emission reduction.

-

Reif, K. (2015). Automotive Mechatronics. Springer Vieweg.

↩ -

Barton, D. C., & Fieldhouse, J. D. (2009). Automotive Chassis Engineering Powertrain Chassis System and Vehicle Body. Elsevier.

↩ -

Denton, T., & Pells, H. (2022). Automotive Technician Training, Second Edition. Routledge.

↩ -

Stone, R. (2012). Introduction to Internal Combustion Engines, Fourth Edition. Macmillan.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.