This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

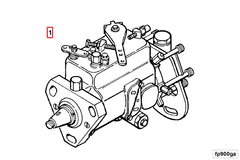

The Cummins 3916669 Fuel Injection Pump is a critical component in the operation of heavy-duty trucks. It is essential for the fuel delivery system, ensuring that the engine receives the precise amount of fuel needed for optimal performance. This part is designed to deliver fuel to the engine cylinders at the correct pressure and timing, which is vital for efficient combustion and overall engine functionality 2.

Basic Concepts of Fuel Injection Pumps

Fuel injection pumps are fundamental to the operation of diesel engines. Their primary function is to deliver fuel to the engine cylinders under high pressure. This process ensures that the fuel is atomized properly, leading to efficient combustion. Precise fuel metering is essential for maintaining engine performance, fuel efficiency, and emissions standards. The pump must operate within specific parameters to ensure that the fuel is delivered at the right time and in the right quantity 1.

Purpose of the Cummins 3916669 Fuel Injection Pump

The Cummins 3916669 Fuel Injection Pump plays a significant role in the operation of a truck by delivering fuel to the engine cylinders at the correct pressure and timing. This ensures that the fuel is atomized properly, leading to efficient combustion. The pump’s ability to maintain precise fuel delivery contributes to the overall performance and efficiency of the engine. It is designed to work in harmony with the engine’s requirements, ensuring that the fuel system operates smoothly under various conditions 2.

Key Features

The Cummins 3916669 is characterized by several key features. Its design incorporates advanced technology to ensure reliable performance. The pump is constructed using high-quality materials that enhance its durability and resistance to wear. Additionally, it may include unique technological advancements such as improved seals and precision-machined components, which contribute to its efficiency and longevity 2.

Benefits

The Cummins 3916669 offers several benefits. It contributes to improved fuel efficiency by ensuring that fuel is delivered precisely when needed. This leads to enhanced engine performance, as the engine operates more efficiently with optimal fuel delivery. The pump’s reliability in various operating conditions ensures that the truck maintains performance even under demanding situations. Additionally, its design helps in reducing emissions, contributing to environmental sustainability 2.

Troubleshooting and Maintenance

Common issues with the Cummins 3916669 may include leaks, inconsistent fuel delivery, or pump failure. Diagnostic procedures involve checking for proper fuel pressure, inspecting for leaks, and ensuring that the pump is receiving the correct electrical signals. Regular maintenance practices, such as cleaning the pump and replacing worn-out components, are essential for ensuring optimal performance and longevity. Following the manufacturer’s guidelines for maintenance can help prevent many common issues 2.

Integration with Engine Management Systems

The Cummins 3916669 integrates with modern engine management systems, including electronic control units (ECUs) and sensors. This integration allows for optimized fuel delivery and engine performance. The ECU monitors various parameters and adjusts the fuel delivery accordingly to ensure that the engine operates within optimal conditions. Sensors provide real-time data to the ECU, allowing for precise control over the fuel injection process 2.

Environmental Impact

The use of the Cummins 3916669 contributes to reduced emissions and improved fuel economy. By ensuring precise fuel delivery, the pump helps in minimizing the amount of unburned fuel, which reduces emissions. Improved fuel economy also means that less fuel is consumed over time, contributing to sustainable transportation practices. The pump’s efficiency plays a role in lowering the overall environmental impact of heavy-duty trucks 2.

Historical Development

The development of fuel injection technology has seen significant milestones, with Cummins playing a notable role. Over the years, Cummins has innovated in the design and manufacturing of fuel injection pumps, leading to more efficient and reliable components. The evolution of this technology has resulted in pumps that offer better performance, durability, and environmental benefits. Cummins’ commitment to innovation continues to drive the advancement of fuel injection systems 2.

Cummins Company Overview

Cummins Inc. is a global leader in the design and manufacturing of diesel engines and related technologies. With a rich history of innovation, Cummins has established a strong global presence. The company is committed to advancing diesel engine technology, focusing on efficiency, reliability, and sustainability. Cummins’ expertise in fuel injection systems is a testament to its dedication to providing high-quality components that enhance the performance of heavy-duty trucks 2.

Role of Part 3916669 Fuel Injection Pump in Engine Systems

The 3916669 is an integral component in the fuel delivery system of an engine, working in concert with several other components to ensure efficient and precise fuel delivery.

When the engine is operational, the base fuel pump draws fuel from the tank and delivers it to the Fuel Injection Pump. The Fuel Injection Pump then takes this fuel and pressurizes it to the required levels for injection into the engine’s combustion chambers.

This pressurized fuel is then delivered to the fuel injectors, which are responsible for spraying the fuel into the combustion chambers at the precise moment needed for optimal engine performance. The timing and amount of fuel delivered are controlled by the engine’s electronic control unit (ECU), which receives input from various sensors throughout the engine system.

The Fuel Injection Pump must work seamlessly with the ECU to maintain the correct fuel pressure and delivery rate. Any discrepancies can lead to inefficient combustion, reduced engine performance, or increased emissions.

Conclusion

In summary, the 3916669 plays a significant role in the fuel delivery process, ensuring that the engine receives the correct amount of pressurized fuel at the right time for optimal performance and efficiency. Its integration with modern engine management systems and its contribution to reduced emissions and improved fuel economy make it a vital component in the operation of heavy-duty trucks.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.