This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

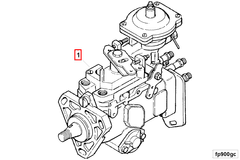

The Cummins 3917523 Fuel Injection Pump is a component designed for use in commercial truck engines. It plays a significant role in the fuel delivery system, ensuring that the engine receives the precise amount of fuel needed for optimal performance. This part is integral to the efficient operation of diesel engines, contributing to both power output and fuel economy.

Basic Concepts of Fuel Injection Pumps

A fuel injection pump is a device that delivers fuel to the engine’s combustion chambers. It operates by pressurizing fuel and injecting it into the cylinders at specific intervals, which are determined by the engine’s operational requirements. In diesel engines, the fuel injection pump is particularly important because it must deliver fuel at high pressure to ensure proper atomization and combustion. There are two primary types of fuel injection systems: mechanical and electronic. Mechanical systems rely on physical components and cam-driven mechanisms to control fuel delivery, whereas electronic systems use sensors and computer controls to manage injection timing and quantity more precisely 1.

Purpose of the Cummins 3917523 Fuel Injection Pump

The Cummins 3917523 Fuel Injection Pump is designed to deliver precise amounts of fuel to the engine cylinders at the correct time. This ensures that the fuel is atomized properly and combusts efficiently, which is crucial for the engine’s performance and fuel economy. By maintaining accurate fuel delivery, the pump helps to optimize the engine’s power output and efficiency.

Key Features

The Cummins 3917523 Fuel Injection Pump features a robust design that incorporates high-quality materials to ensure durability and reliability. It includes advanced technological features such as precision engineering and electronic controls, which enhance its functionality and performance. The pump is designed to withstand the demanding conditions of commercial truck operations, providing consistent and reliable fuel delivery.

Benefits

Using the Cummins 3917523 Fuel Injection Pump offers several advantages. It contributes to improved fuel efficiency by ensuring that fuel is delivered precisely when needed, which reduces waste and enhances engine performance. The pump’s reliable operation also contributes to the overall reliability of the truck, minimizing downtime and maintenance costs. Additionally, its advanced features help to reduce emissions, making it an environmentally friendly choice.

Installation and Integration

Installing the Cummins 3917523 Fuel Injection Pump involves several steps and considerations. It is important to follow the manufacturer’s guidelines to ensure proper integration with the truck’s engine system. This may include making necessary modifications or adjustments to accommodate the pump. Careful attention to detail during installation will help to ensure that the pump operates efficiently and reliably.

Troubleshooting and Maintenance

Common issues that may arise with the Cummins 3917523 Fuel Injection Pump include fuel delivery inconsistencies and pump wear. Diagnostic procedures should be followed to identify and address these issues promptly. Regular maintenance, such as cleaning and inspecting the pump, can help to ensure its longevity and optimal performance. Following the manufacturer’s recommended maintenance schedule is crucial for preventing problems and extending the pump’s service life.

Performance and Efficiency

The Cummins 3917523 Fuel Injection Pump plays a role in the overall performance and efficiency of the truck engine. By delivering fuel precisely when needed, it helps to optimize fuel economy and power output. The pump’s advanced features contribute to its ability to maintain consistent performance under varying operating conditions, ensuring that the engine operates efficiently and reliably.

Technological Advancements

The Cummins 3917523 Fuel Injection Pump incorporates several technological features that enhance its functionality. Precision engineering ensures accurate fuel delivery, while electronic controls allow for fine-tuning of injection timing and quantity. These advancements contribute to the pump’s ability to deliver consistent performance and reliability, even in demanding commercial truck applications.

Environmental Impact

Using the Cummins 3917523 Fuel Injection Pump can have positive environmental benefits. Its precise fuel delivery helps to reduce emissions by ensuring that fuel is combusted efficiently. Additionally, improved fuel efficiency means that less fuel is consumed overall, which contributes to lower greenhouse gas emissions. These factors make the pump a valuable component in efforts to reduce the environmental impact of commercial truck operations.

Cummins Overview

Cummins Inc. is a well-established company with a strong reputation in the diesel engine industry. Founded in 1919, Cummins has a long history of innovation and quality in diesel engine components. The company is committed to developing advanced technologies that enhance the performance, efficiency, and reliability of its products. Cummins’ dedication to innovation and quality has earned it a respected place in the industry, making it a trusted choice for commercial truck operators 2.

Cummins Fuel Injection Pump 3917523 Compatibility

The Cummins Fuel Injection Pump part number 3917523 is designed to be compatible with a range of engines, ensuring reliable performance and efficiency. This part is engineered to meet the demands of various applications, providing precise fuel delivery and optimal engine performance.

Engine Compatibility

-

4B3.9 Series

- The 3917523 fuel injection pump is specifically engineered to fit seamlessly with the 4B3.9 engine series. This compatibility ensures that the pump can handle the unique requirements of this engine model, delivering the necessary fuel pressure and timing for smooth operation.

-

Group Compatibility

- The 3917523 fuel injection pump is also compatible with other engines within the same family or group as the 4B3.9 series. This broad compatibility allows for easier maintenance and repair, as the same part can be used across multiple engine models, reducing inventory needs and simplifying the supply chain.

Performance and Reliability

-

The Cummins 3917523 fuel injection pump is built to deliver consistent performance, ensuring that engines operate at peak efficiency. This reliability is critical for maintaining the longevity and performance of the engine, especially in demanding applications.

-

The design of the 3917523 pump ensures that it can withstand the rigors of continuous operation, providing a durable solution for engine maintenance and repair.

Role of Part 3917523 Fuel Injection Pump in Engine Systems

The part 3917523 Fuel Injection Pump, specifically the Bosch injection pump, is integral to the efficient operation of diesel engine systems. This component is responsible for delivering precise amounts of fuel into the combustion chamber at the exact moment required for optimal engine performance.

Integration with Engine Components

-

Fuel System: The Bosch injection pump is a key component in the fuel system. It works in conjunction with the fuel tank, fuel lines, and fuel filters to ensure a consistent and clean fuel supply. The pump pressurizes the fuel, which is then delivered to the injectors.

-

Injectors: The pressurized fuel from the pump is directed to the injectors. These injectors atomize the fuel into fine particles, ensuring a more complete and efficient combustion process. The timing and quantity of fuel delivery are controlled by the pump, directly influencing engine power and efficiency.

-

Engine Control Unit (ECU): Modern diesel engines often incorporate an ECU that communicates with the injection pump. The ECU monitors various engine parameters such as RPM, load, and temperature. It sends signals to the pump to adjust fuel delivery accordingly, ensuring optimal performance under varying conditions.

-

Turbocharger: In turbocharged diesel engines, the fuel injection pump must work in harmony with the turbocharger. The pump delivers more fuel to match the increased air intake provided by the turbocharger, allowing for higher power output without compromising efficiency.

-

Common Rail System: In engines equipped with a common rail fuel system, the Bosch injection pump plays a vital role in maintaining the high-pressure fuel rail. It ensures that the fuel is always available at the required pressure for the injectors to operate effectively.

-

Glow Plugs: During cold starts, glow plugs are used to preheat the combustion chamber. The injection pump must deliver fuel precisely when the glow plugs have heated the chamber sufficiently, ensuring smooth starts in cold conditions.

-

Exhaust Gas Recirculation (EGR) System: The pump must also adapt to the EGR system, which recirculates a portion of the exhaust gas back into the intake tract to reduce nitrogen oxides (NOx) emissions. The pump adjusts fuel delivery to compensate for the altered air-fuel mixture.

-

Sensors and Feedback Mechanisms: Various sensors, such as the mass airflow sensor, oxygen sensor, and throttle position sensor, provide feedback to the ECU. The ECU uses this data to fine-tune the injection pump’s operation, ensuring that the engine runs smoothly and efficiently under all conditions.

By precisely controlling the fuel delivery, the Bosch injection pump (part 3917523) ensures that the engine operates efficiently, produces maximum power, and meets emission standards. Its integration with other engine components is essential for the overall performance and reliability of the engine system.

Conclusion

The Cummins 3917523 Fuel Injection Pump is a critical component in the efficient operation of commercial truck engines. Its precise fuel delivery, robust design, and advanced technological features contribute to improved engine performance, fuel efficiency, and reduced emissions. Proper installation, maintenance, and integration with other engine components are essential for maximizing the benefits of this Cummins part.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.